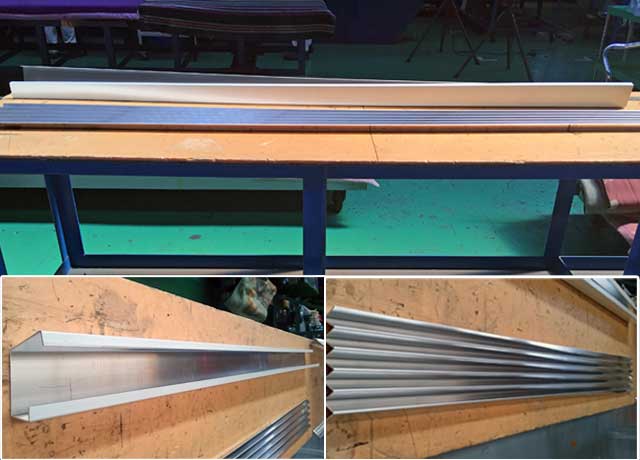

Mirror Finish

High quality metal material sheet press bending (8000mm) at once

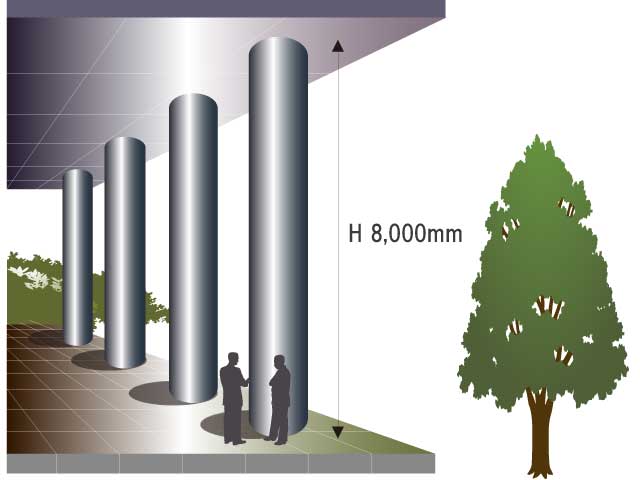

With this machine, Kikukawa is able to bend metal sheets up to 8m in length. Having one of the largest bending machines in the industry allows the fabrication of over-sized or extra-long panels. The custom NC press machine was installed in Kikukawa’s factory to realise a project that required minimal-joints. The machine is able to bend stainless steel, bronze (copper alloy), steel and aluminium up to 6mm thickness.

By combining our craftsmanship and machinery, KIKUKAWA is able to undertake extra-long and difficult bending that meets our high-quality standards.

| Main Features | -Extra-long (8m) bending with one of the largest NC bending machines in the industry -High quality and high precision bending -Over-sized and extra-long bending possible -Realisation of designs with minimal joints |

|---|---|

| Name/Type | -HD6008NT -8m bending machine -NC press brake -Metalwork bender |

| Fabricator | AMADA CO., LTD. |

| Applicable Materials | -Stainless Steel -Steel -Aluminium -Bronze (Copper Alloys) Maximum thickness 6mm |

| Categories | -Sheet metal bending -Step bending -Corrugating -Roll bending (radius bending) -Taper bending |

| Maximum Workable Size | 500mm(W) x 8000mm(L) *Please consult us for any products over this size |

■Overview of the 8m Bending Machine

The eco-friendly bending machine is based on AMADA’s HD-NT series and has many features that ensure high-quality bending. Together with our collection of dies it expands the possibilities of bending.

1) Auto features

With the NC control and the auto-crowning feature, the machine and KIKUKAWA’s expertise ensure precise and consistent bending.

2) Various dies

KIKUKAWA holds over 30 dies to realise various bespoke bending needs. The collection includes custom-made roll bending dies, diverse radius dies and deep bending dies.

With KIKUKAWA’s experience, these dies allow us to fabricate shapes such as cones, corrugated fans or products such as round column covers.

3) Eco-friendly

The Hybrid drive system is engineered for low energy consumption and requires less hydraulic fluid than conventional machines.

For more information about the machinery (Jump to AMADA’s page):

http://www.amada.com/america/down-acting-hd-2204l-nt-

■KIKUKAWA’s Bending Technology

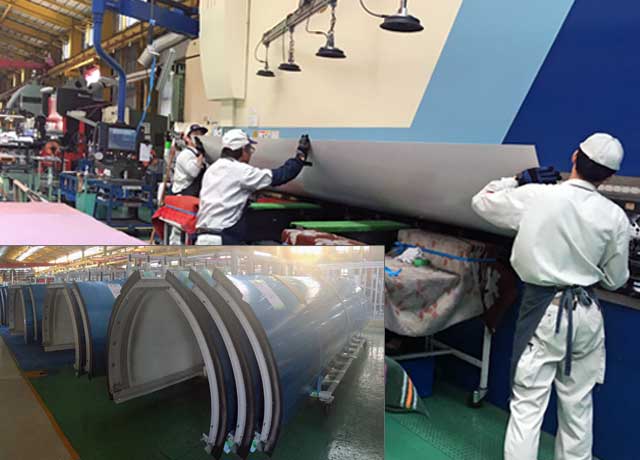

The machine alone is not enough to realise the high-quality products that KIKUKAWA fabricates. The additional length and thus the weight of the product increases the difficulty of the metalworking process. The longer the bend, the more chances there are for inconsistency in the bend. It also necessitates teamwork and extra care to ensure that no scratches are made on the surface of the material.

To ensure the quality of the bend, KIKUKAWA’s operators utilise their knowledge and experience to select the best bending procedure required.

Here are some examples of metalwork KIKUKAWA can realise by combining our technology and other metalworking facilities:

-fan shaped corrugation

-cones

-fabrication of oversized (not available in the market) material, and panels

-extra long round column covers

-corrugating

-twisting

-complex shapes

-double curved panels

■Changing Demand

With the development of 3D CAD and fabrication technology, the complexity and diversity of architectural designs that can be realised continues to expand. As a bespoke architectural metalworker, we are often consulted on the feasibility of unique designs with “minimal joints” or “3D curvatures”.

The addition of this machinery to our factory was one way of responding to this changing demand. While the common maximum workable size is 4~5m, this custom-made machine allows us to fabricate larger sizes.

Along with the large collection of dies, KIKUKAWA continues to hone its know-how to exceed our customer’s requirements.

■Please Consult Us

With our expertise and cutting-edge technology, we choose the most suitable fabrication method and procedure depending on the material, finish and difficulty of the bend. From consultation to fabrication feasibility, please do not hesitate to contact us.

For more information on metalworking capabilities, click here

Custom Metalwork

To make an inquiry, click here

Contact Us

Bent metal samples

Fabrication of round column covers with 8m bending press

Rendering of design that can be actualised with 8m bending machine