January 29, 2019

Bespoke Copper Hood

As a bespoke architectural metalworker, Kikukawa’s main specialty has been in large interior and exterior constructions. As exemplified by the establishment of the interior division earlier this month, Kikukawa is also an expert in small-scale or smaller sized products such as the following copper hood.

The pictures below show the fabrication process. Ultimately meant for a high-end restaurant in Ginza, this space houses counter seats which face the kitchen where the food is served directly from the chef.

Kikukawa’s handcrafted copper hood, a piece that balances both aesthetics and functionality, lies in the centre of this kitchen, contributing to a calming and classic ambiance of the Japanese-style space.

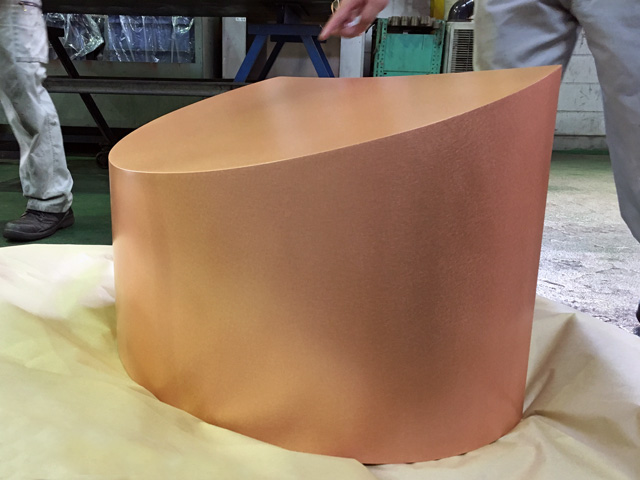

This hood is shaped like a half cylindrical tube, cut diagonally then welded with a lid at the top. It is roughly 630mm in diameter and its height ranges from 245mm to 360mm.

The texture of the copper and the gloss of the clear coating is a beauty in itself

The selected finish is PHL and clear coating. This unique texture stems from the PHL finish which softens the natural red glisten of the copper, and the clear coating which emphasizes its shine. The clear coating allows the natural tint of the copper to be enjoyed for a longer period.

Copper alloys with PHL and clear coating. From the left; copper, bronze and brass. (Please confirm the colours with an actual sample.)

A Kikukawa craftsman carefully applying a coat of the clear coating

With the fabrication of copper products that requires both aesthetic and functionality, the most difficult process is considered to be welding. As copper alloys have a higher thermal conductivity in comparison to other metals such as steel, problems such as welding strength, distortion or discolouration occurs more easily.

At Kikukawa, we overcome these potential issues by applying high-quality bending and cutting, as well as careful welding by expert craftsman that fully utilizes their expertise.

A Kikukawa craftsman carefully welding the copper pieces

Inspecting the copper hood

This project is an example of the OSS (One Stop Solution) system, which means that Kikukawa was responsible for the process from fabrication to installation.

With interior constructions, attention to details influences the product’s quality, in aesthetics and functionality, especially for appliance-related products. Kikukawa will continue to contribute to interior constructions by using its know-how established from bespoke metal constructions.