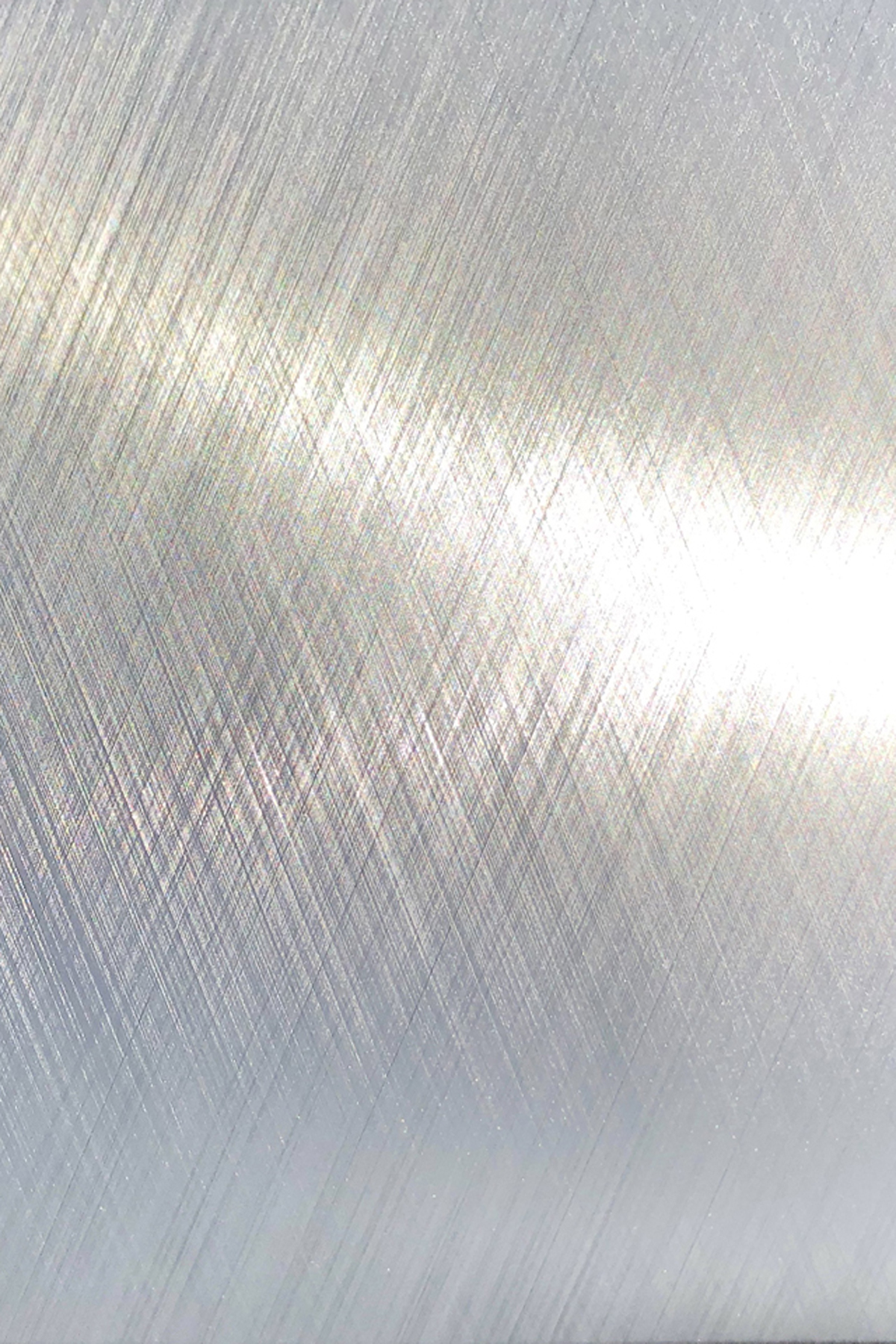

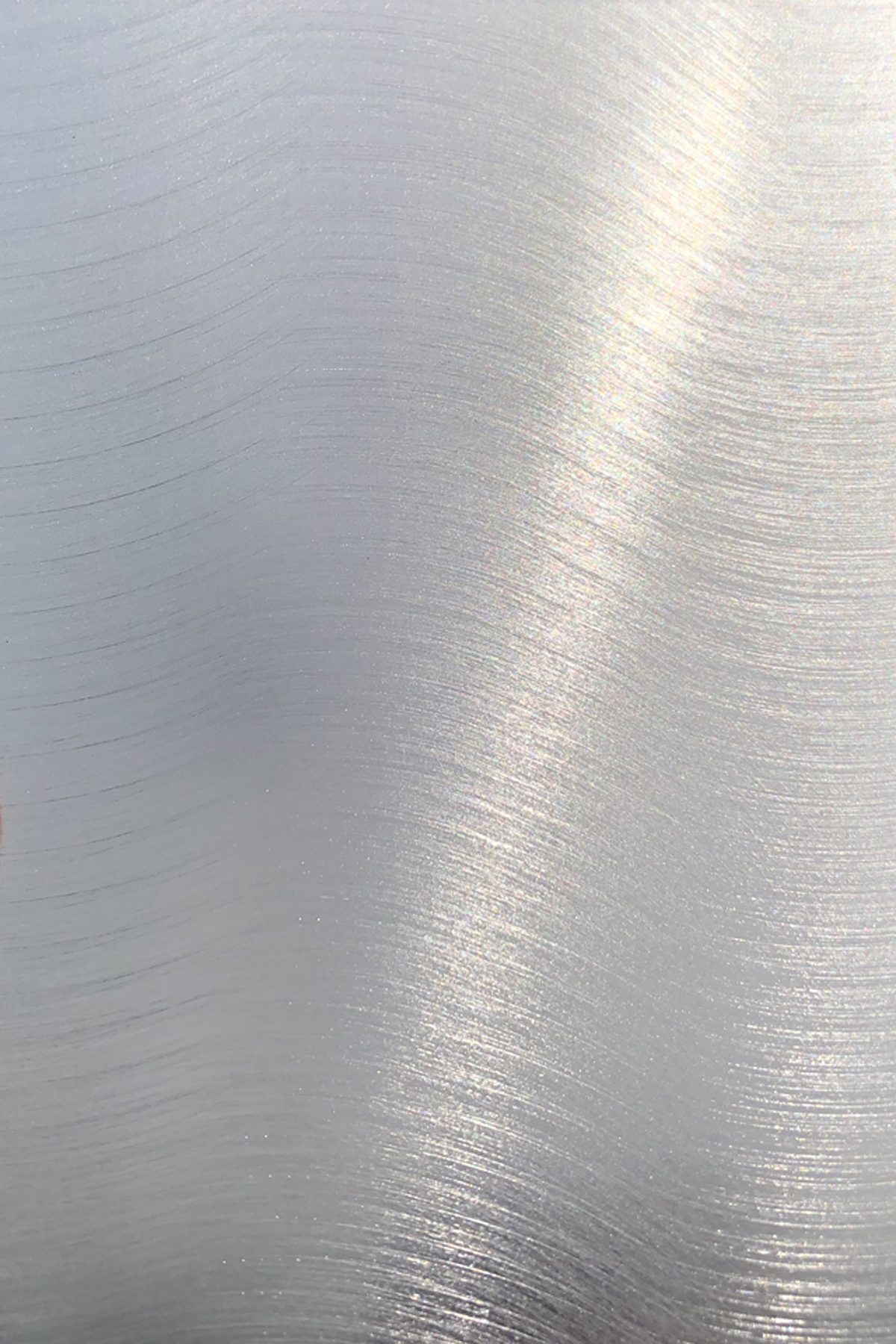

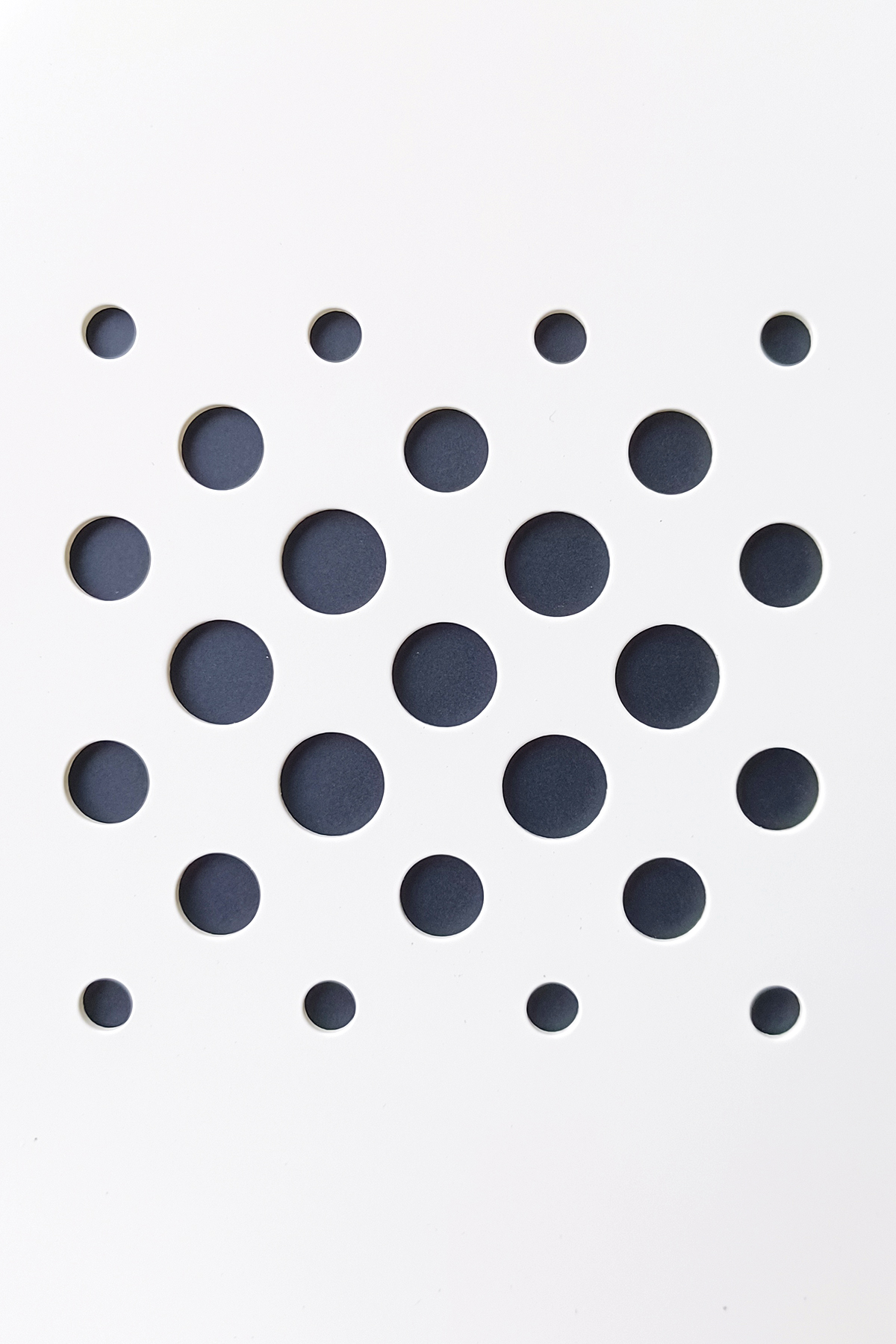

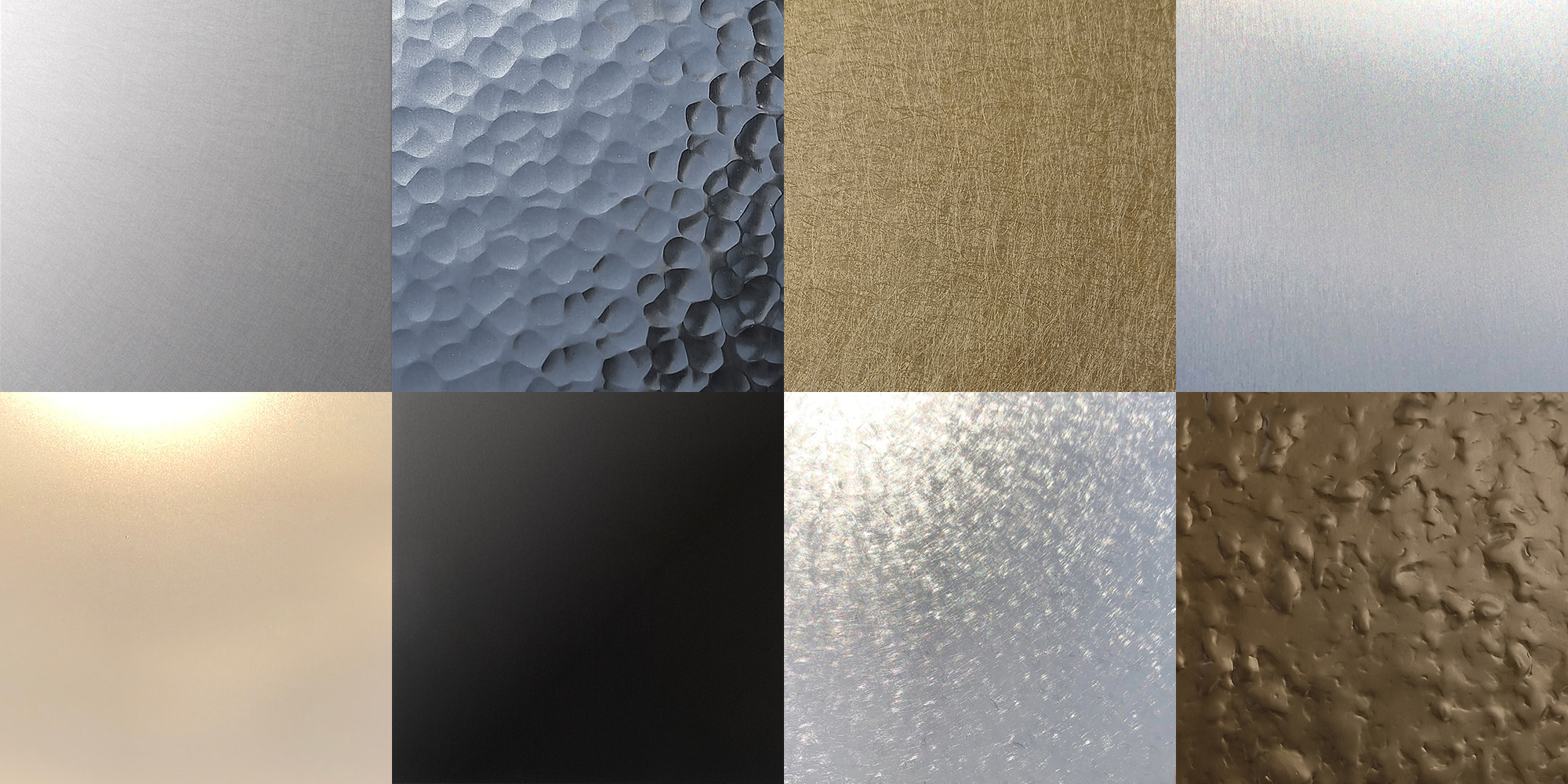

Alumiére is KIKUKAWA’s original finishing series that maximizes the glossiness of aluminium.

Gentle metallic reflection which is different from that of stainless steel is achieved with lightweight aluminium.

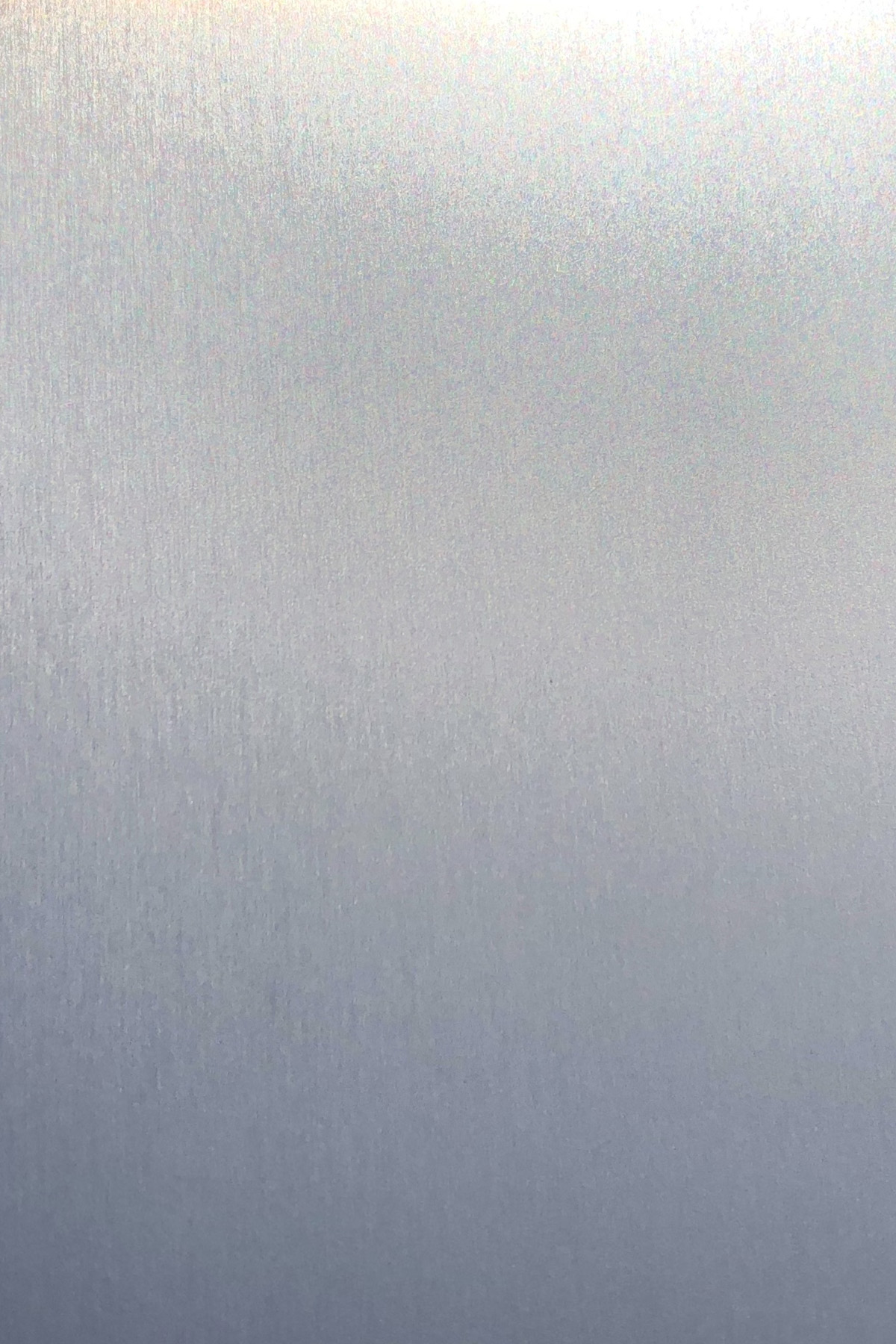

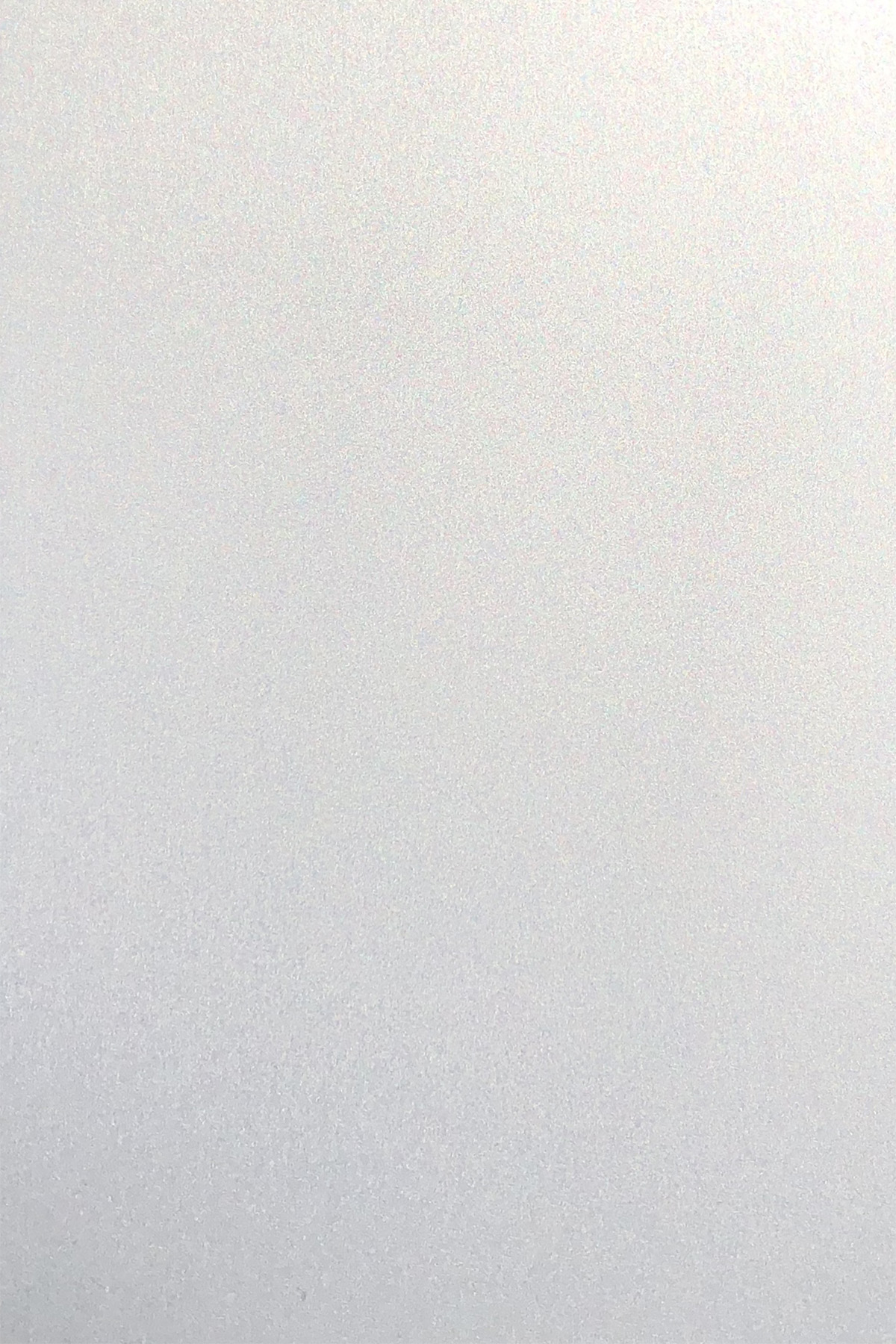

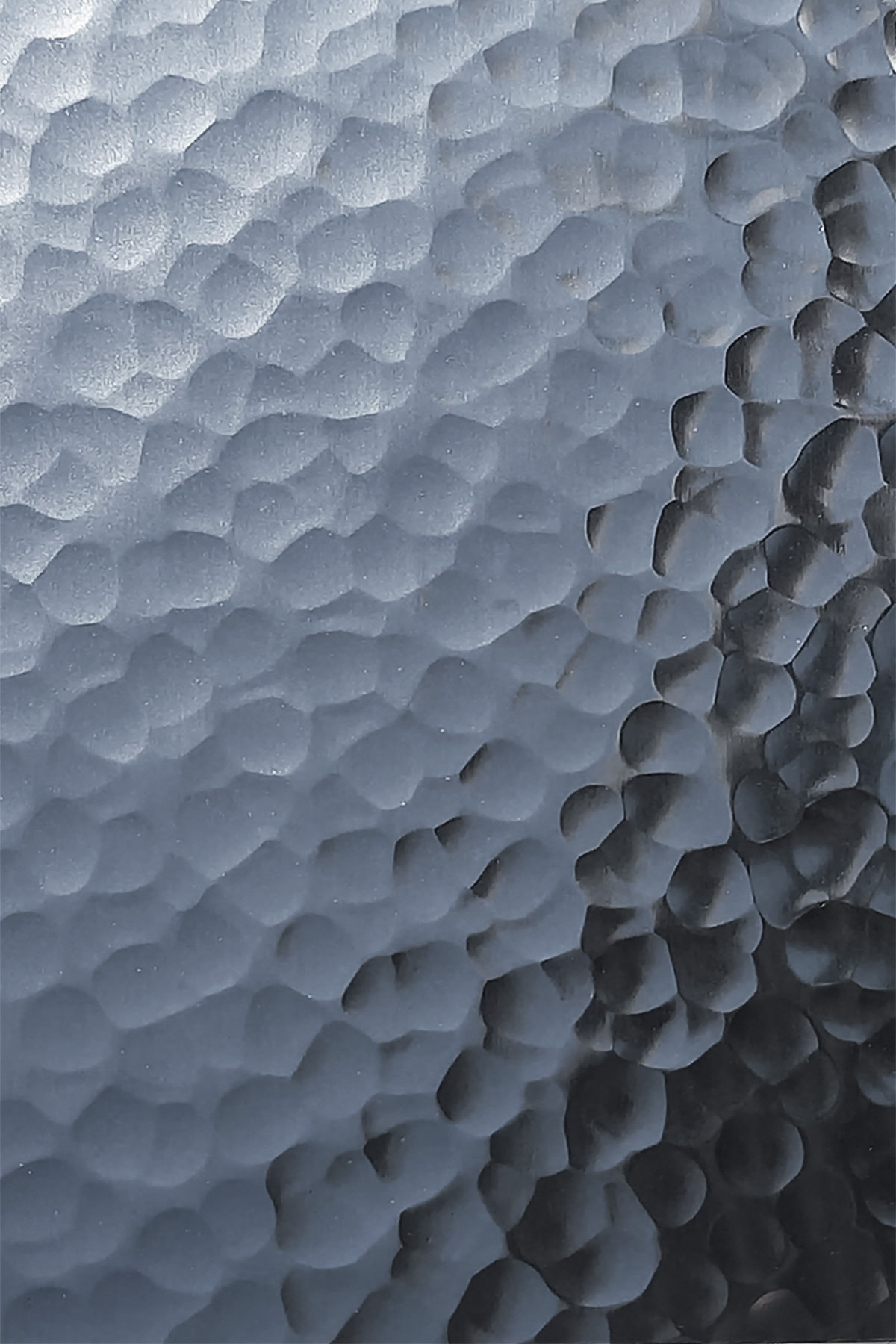

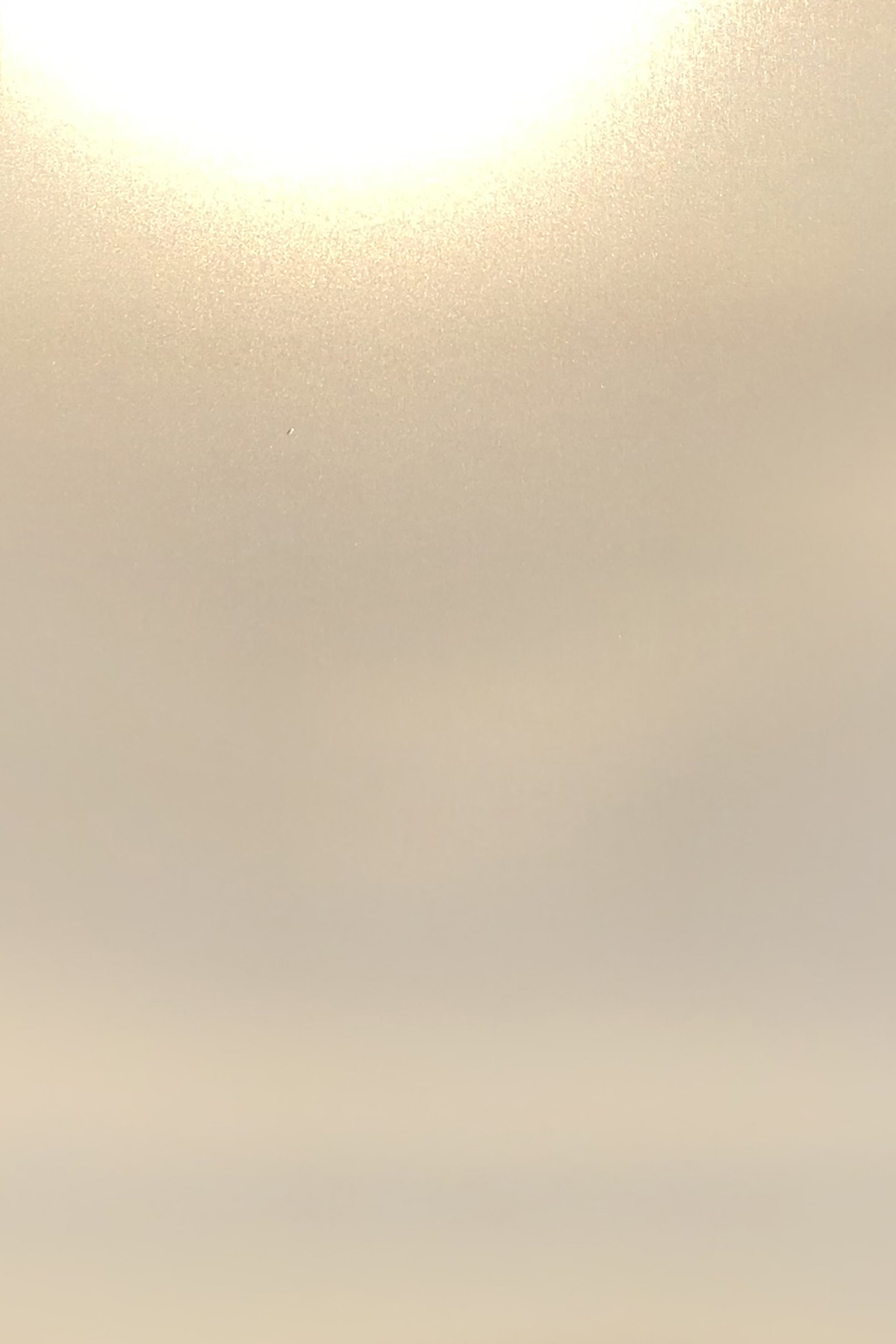

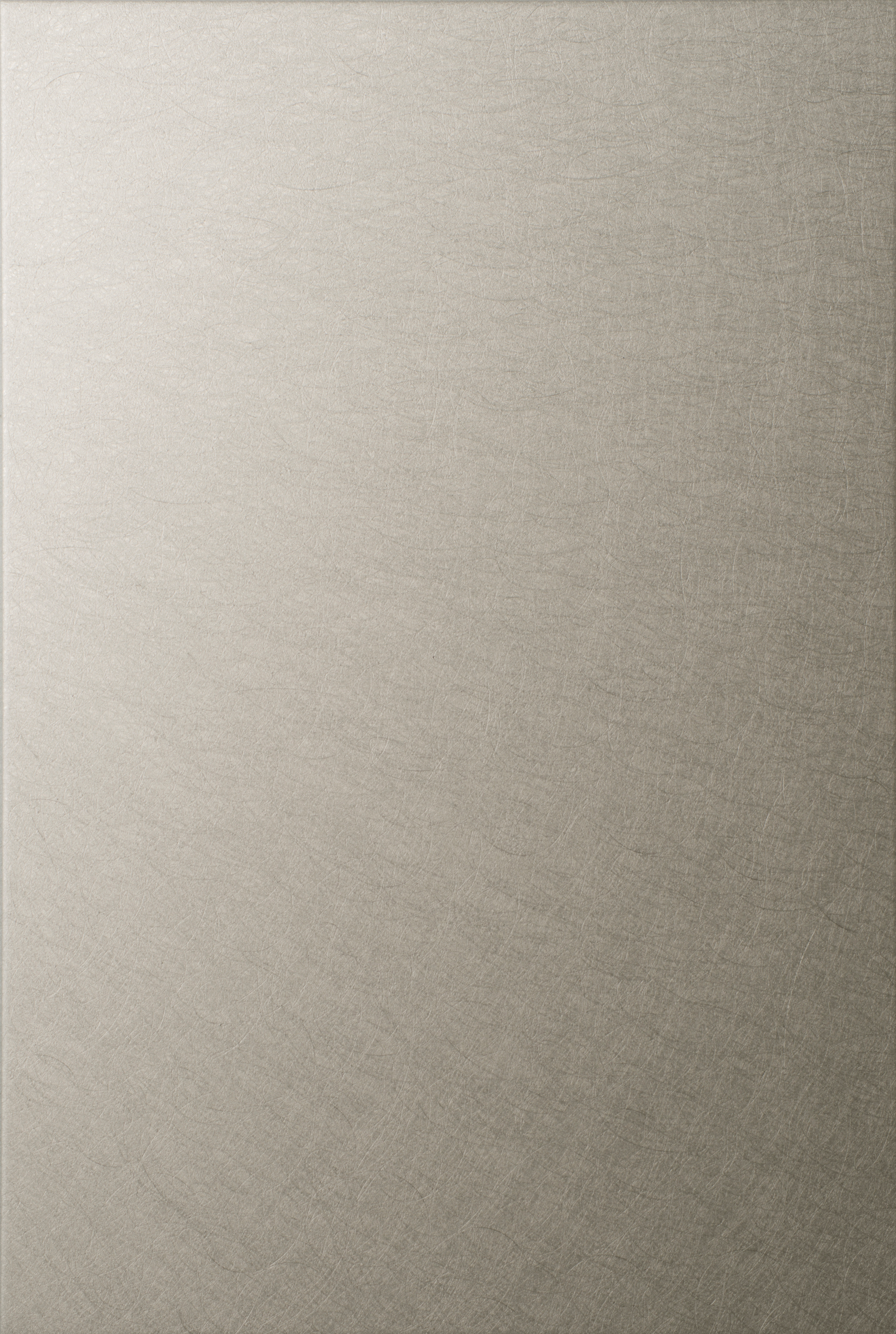

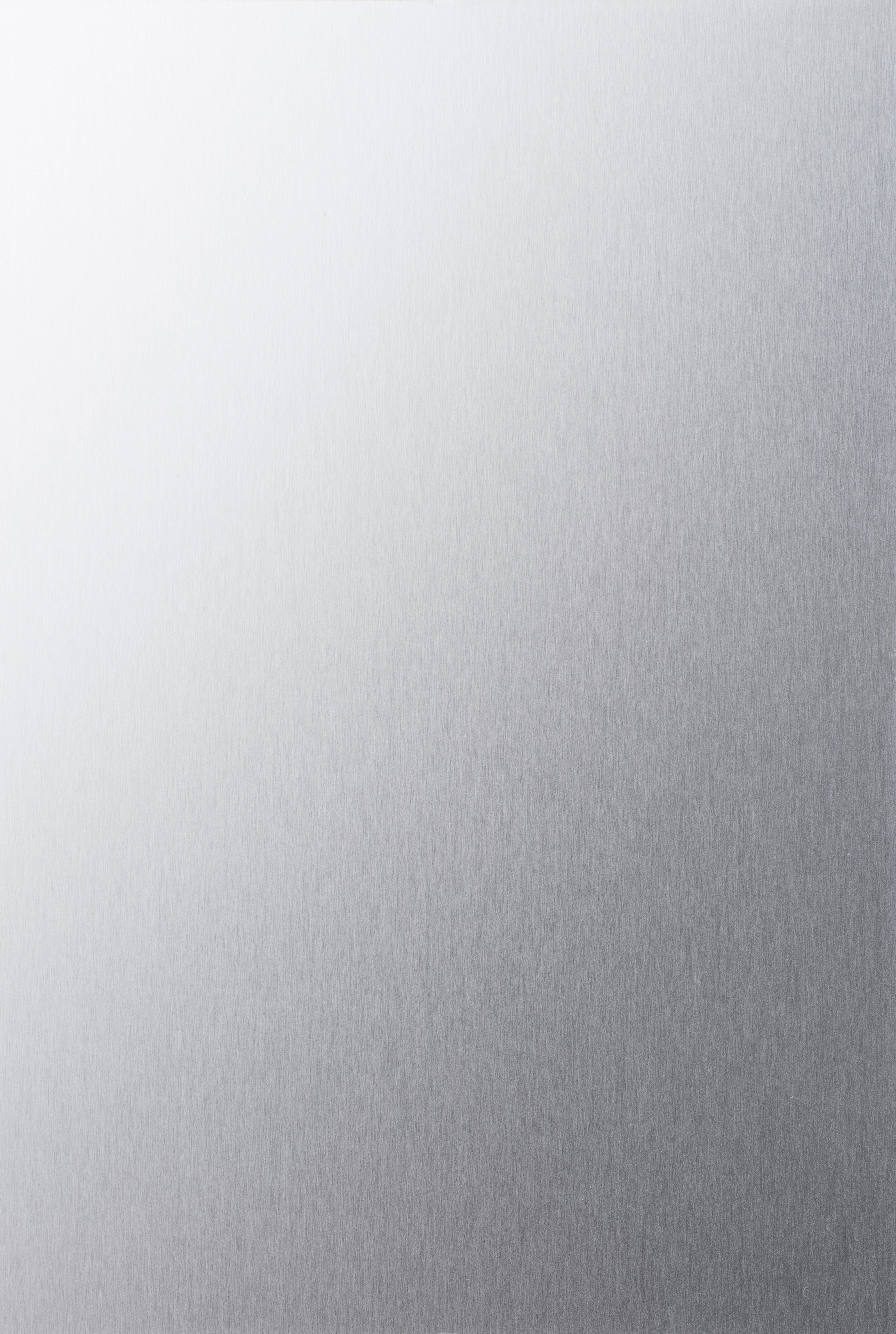

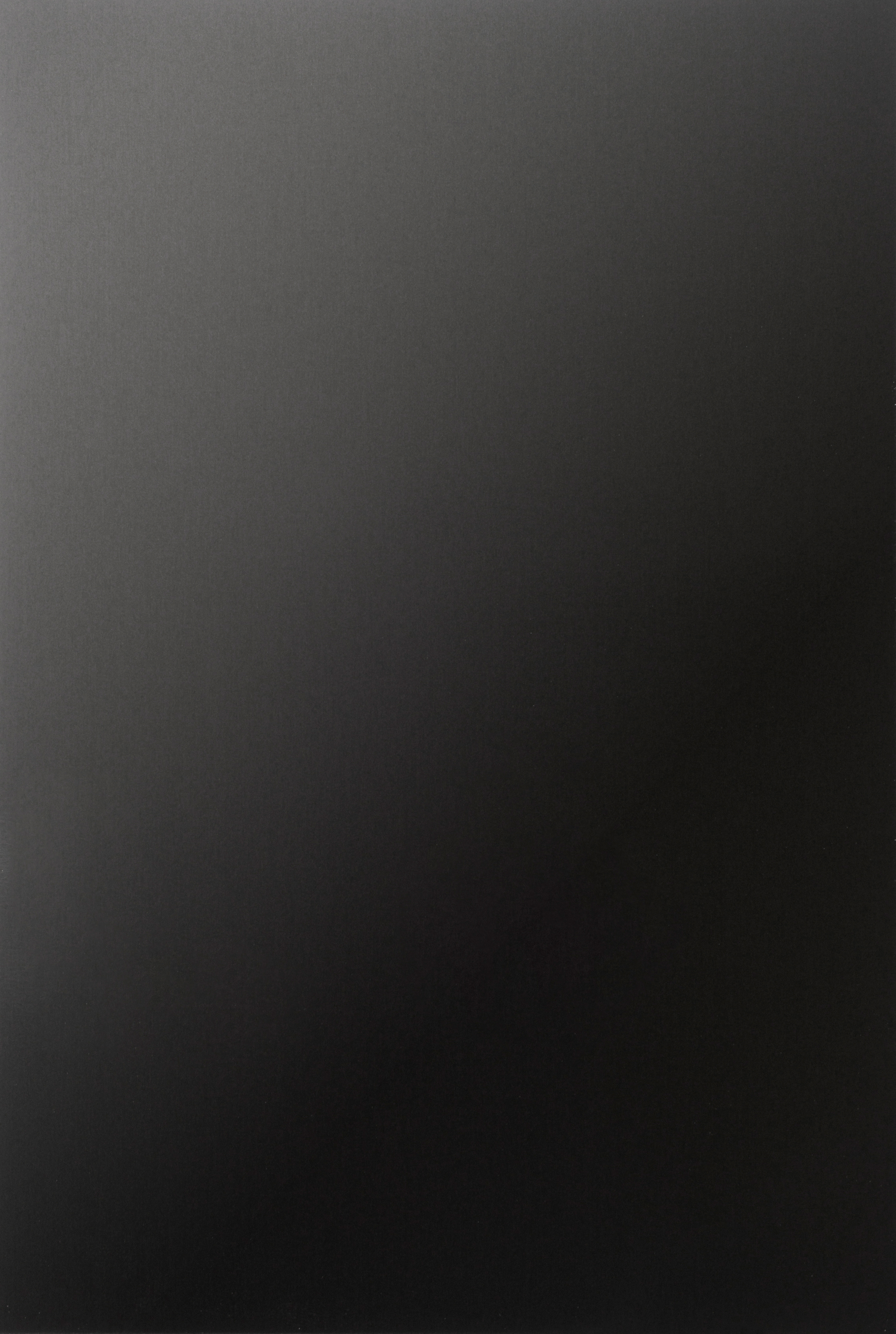

Two different levels of gloss and reflection (Le-01: High Bright Silver / Le-02 Bright Silver) are available for comparison with silver anodized aluminium (Le-03).

Please consult us for both interior and exterior architectural applications.

*This finish is part of the Alumiére sample book.

Aluminium - a silvery-white metal - is widely known for its usage in everyday items such as jewelry, eyeglass frames and Japanese one-yen coins. Light and highly workable, aluminium is used as metal sheets, pipes, and extrusions.

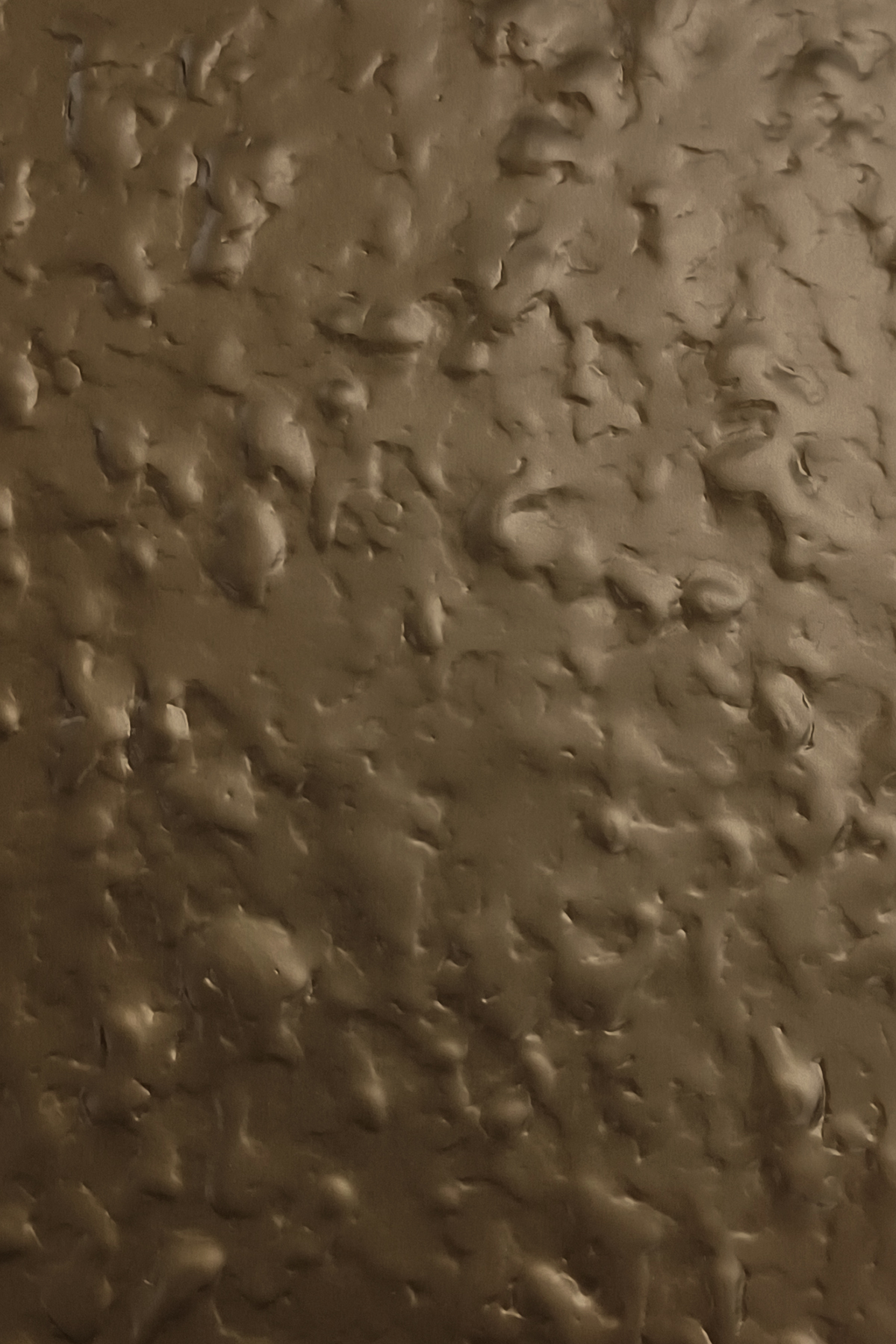

Finishes listed below are excerpts - other colours, gloss levels or embossing may be available upon request.

*Please note that the photos of the samples are guidelines. Please confirm the finish with an actual sample prior to making your final selection.

Click here to check the contents of KIKUKAWA's Aluminium Finish Sample Book