November 13, 2018

Facade Renovation with Galvanized and Zinc Phosphate Coated Steel Panels

Zinc phosphate coated steel elevates the natural crystalline aesthetics of hot-dipped galvanized steel for decorative use. It is recently attracting attention for its natural, luxurious, stately ambiance and gray tones that settle over time – an effect that cannot be actualised with paint coatings.

The resulting colours and patterns of the zinc phosphate coating are highly dependant on conditions such as material composition or the thickness of the material, making the process an art as much as it is science. However, KIKUKAWA has an established quality control to ensure a level of consistency in the finish.

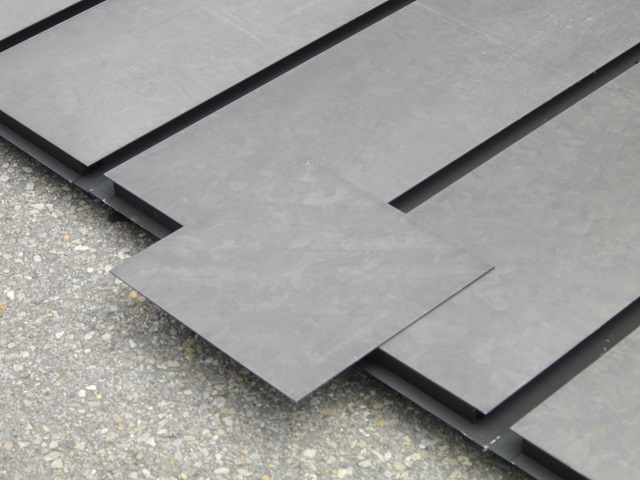

An example of a renovation construction featured today is a facade with hot-dipped galvanized and zinc phosphate coated steel panels. The steel panels were treated with hot-dip galvanization and dark zinc phosphate coating (Phozinc: PZ-03), to be used as the facade of a gallery.

Dark zinc phosphate coated panels form a chic facade

The facade before and after the renovation

While the facade was previously a shop window, the renovated facade is lined with cut-edge 2.3mm thick steel panels. The panels contribute to the establishment of a composed ambiance.

The rectangular hot-dipped galvanized and zinc phosphate coated panels contribute to a Japanese-esque ambiance

The 48 panels form a 15m long wall, with the standard panel size being 283mm (W) x 3220mm (H).

The entrance doors are also lined with hot-dipped and zinc phosphate coated steel panels

The automatic entrance flush doors are lined with similarly dark phosphate coated panels of 2100mm (W) x 2750mm (H).

Comparing an approved finish sample and the actual panels

Inspecting the 48 hot-dipped galvanized and zinc phosphate coated panels

By lining the panels, the consistency of colour is inspected. These panels are installed strategically on-site to ensure a natural colour gradation.

Zinc phosphate coatings have limitations such as size, shape, and difficulties in controlling the finishing colours. However, Kikukawa’s Phozinc is quality controlled with our metal expertise and technology to respond to the project requirements.

For more information on zinc phosphate coating, click here

For more information on Kikukawa’s renovation constructions, click here