February 27, 2018

Stretch Forming

Fabrication of bespoke items comes with its own challenges – R bending complex shaped products is one example.

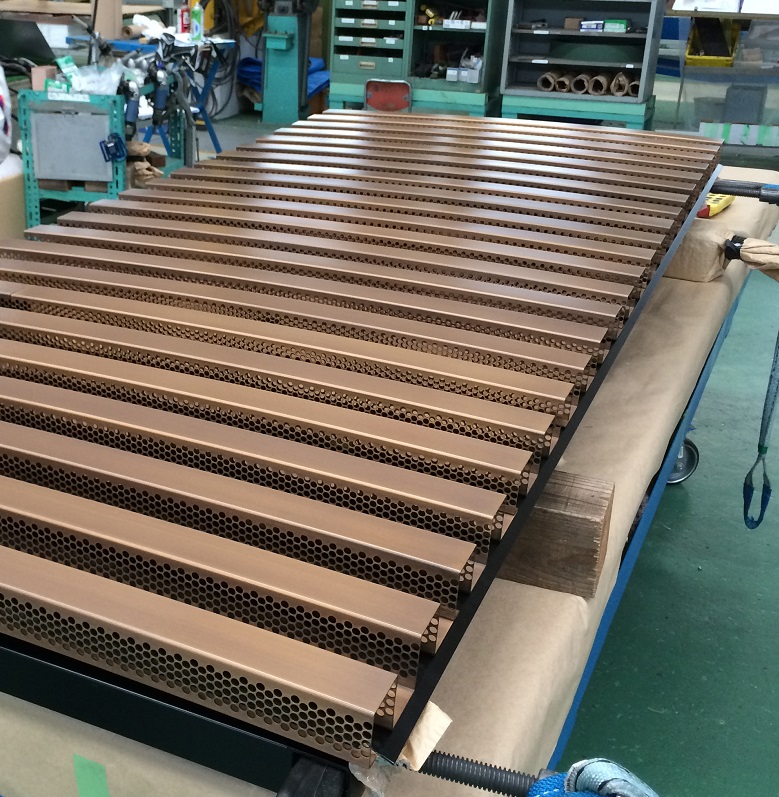

Typically, R bending corrugated parts requires welding pieces, which tends to compromise the aesthetics, consume time and add to the fabrication cost.

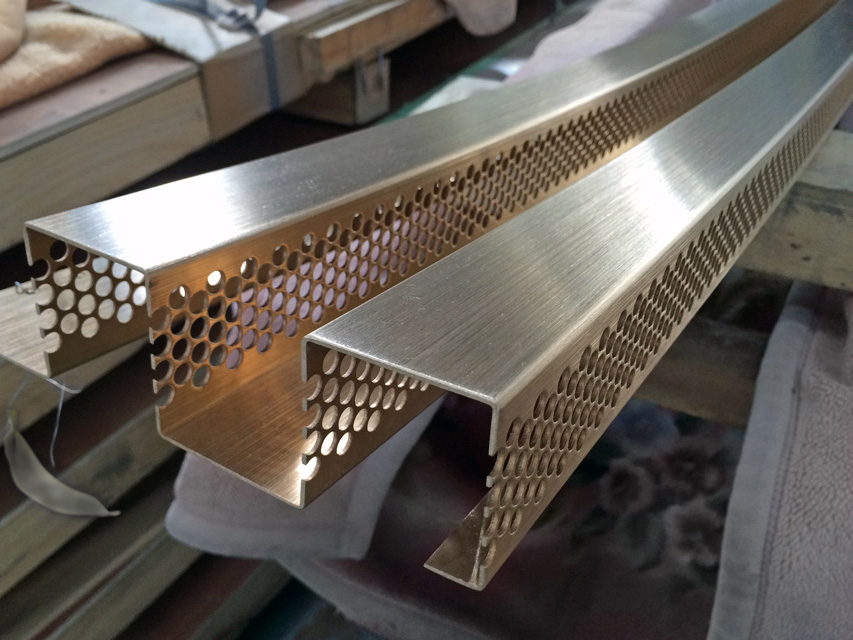

Stretch forming overcomes these difficulties. The produced products are stretched into shape, thus eliminating the need for welding.

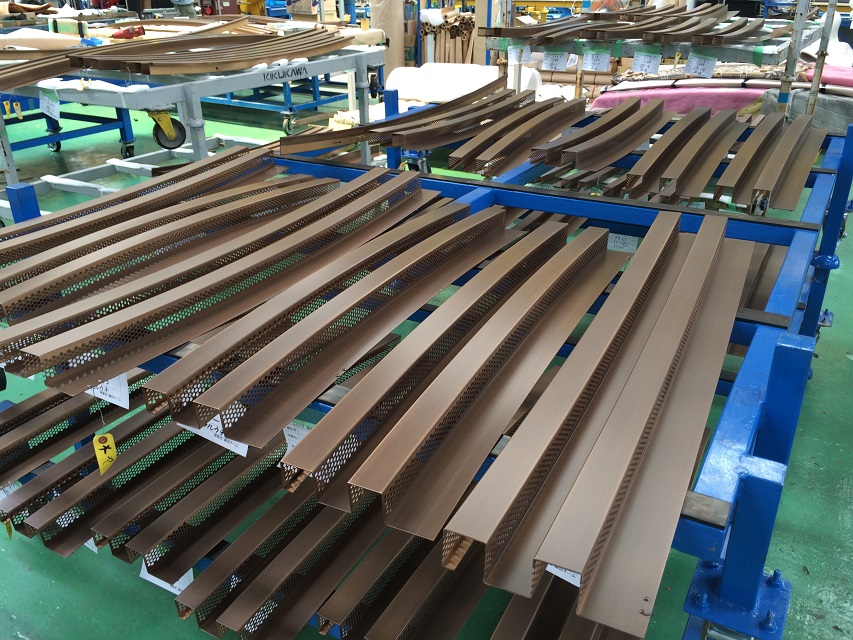

Various corrugated louvres, with various R bending, show the versatility of stretch forming. The perforations at the edge, close to the bent corners, made this process more difficult.

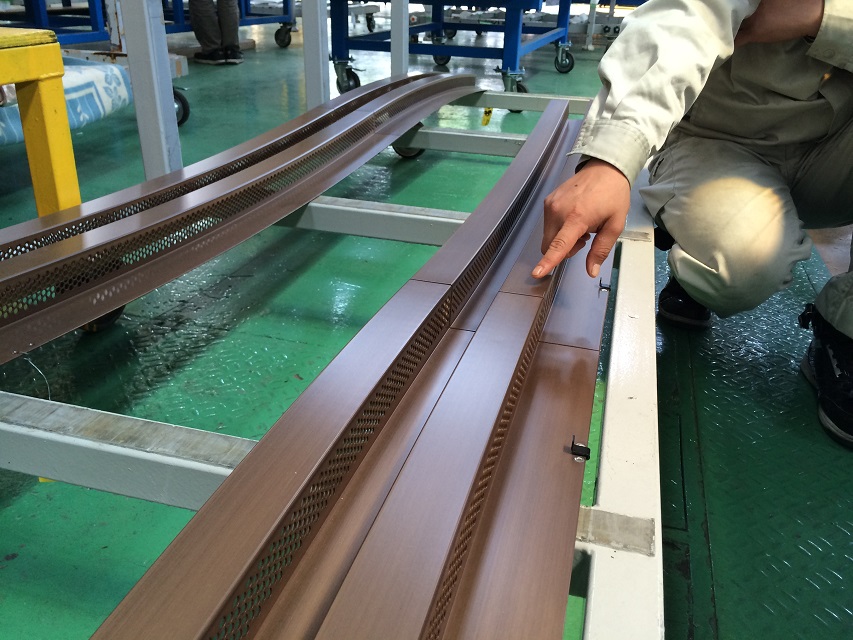

The pointed area shows the joint of two R bent corrugated louvres. Joining R bent pieces are typically more difficult as it requires precision in the R curvatures.

The R bent corrugated louvres are installed, in line with the gentle folds of the facades.

The featured photos are from the Bloomberg project in London.