May 28, 2018

Welding Brass Without Discolouration

Kikukawa has developed a new technology to weld brass without discolouration.

Previously, Kikukawa was able to minimize discolouration by refining its welding technology, however, it was near impossible to remove it. With this new technology, we are able to fabricate over-sized brass panels or weld extrusions without discolouration.

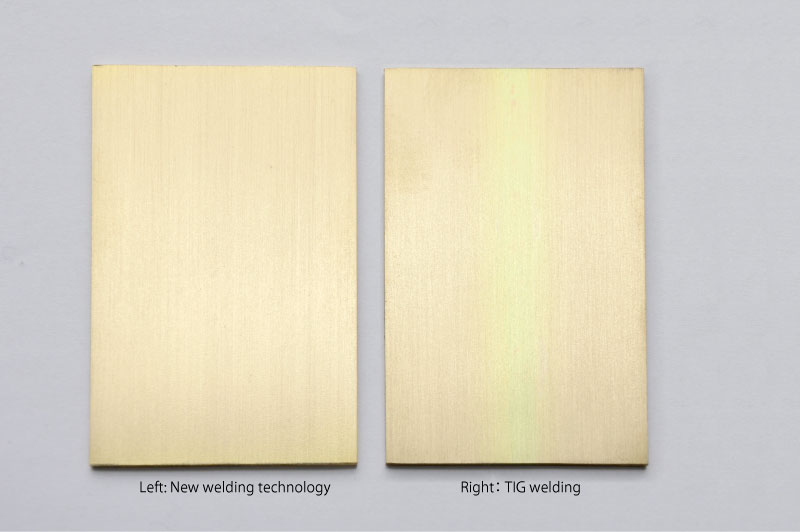

Two brass samples, welded at the center. Left: New welding technology. Right: TIG welding. As the picture shows, discolouration can only be observed from TIG welded sample.

Brass is a widely used material in architecture, as door handles, handrails, faucets, signboards and others. From the gold hue of new brass to the rich brown hues of patinated brass, the changing colour is part of the material’s appeal.

However, it has not been a common choice in larger products for various reasons.

For instance, casting, extruding or machining brass to the necessary quality meant longer fabrication lead time and higher costs.

To combat discolouration from welding brass, brazing was used for products that required less welding strength. However, brazing requires experience and the filler material lead to slight discolourations.

With the new technology developed by Kikukawa, we overcame these difficulties so that fabrications of larger products or products that hope to utilize the original texture and hues of brass are possible. Furthermore, as the material is not exposed to discolouration, finishes such as sulfurization are also possible.

For more information, testing or manufacturing feasibility, contact us