June 27, 2018

Minimal Distortion And High Strength Welding Brass

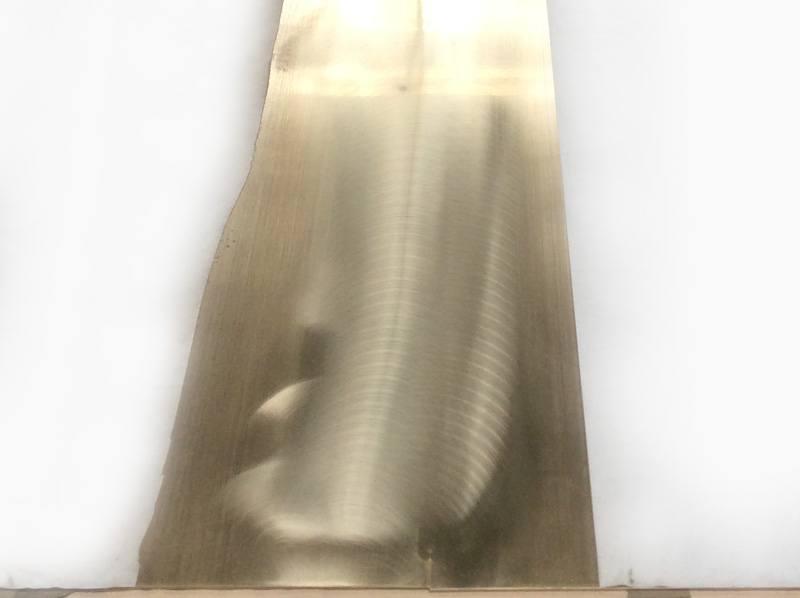

Brass is a popular material for interior use, for its chic gold texture and high workability.

Kikukawa is able to weld extra-long and 3 dimensionally curved panels with minimal distortion.

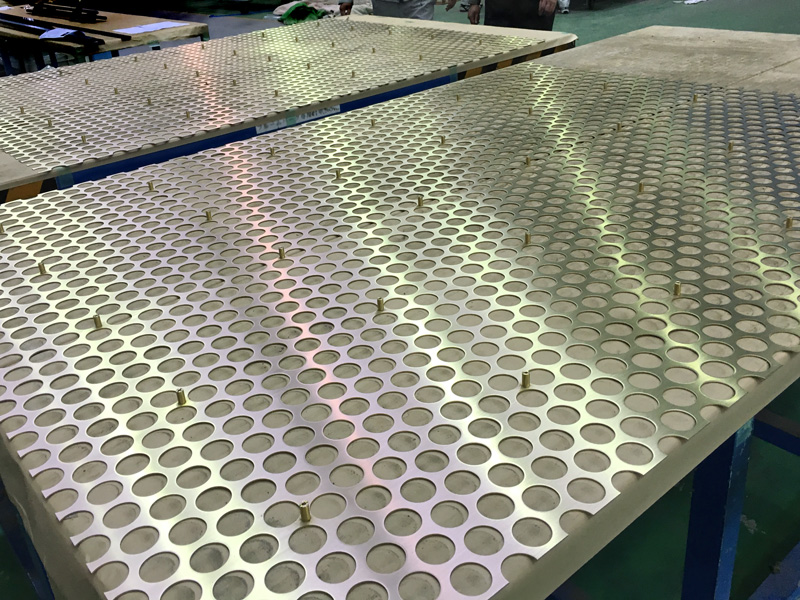

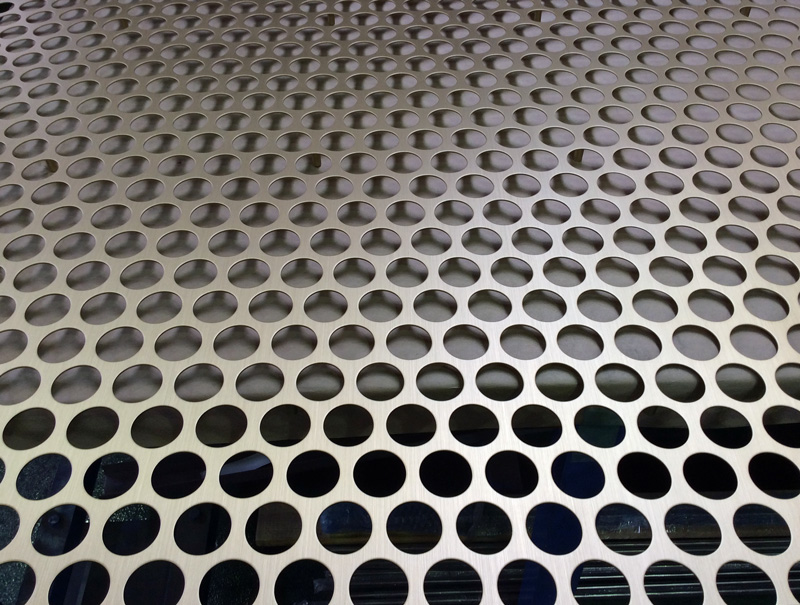

Here is a perforated brass metal product over the market available material sheet size. Finished with hair-line and clear coating, a texture that fully displays the beauty of brass.

Perforated brass panel, welded vertically between the second and third perforation from the bottom left corner.

To satisfy the requirements, welded brass metal sheets with high strength, minimal distortion and minimal discolouration were necessary.

While the final product size is 2140mm (W) x 1604mm (L), the largest market available sheet is 1250mm (W) x 3050mm (L). To ensure the necessary strength for perforation with typical welding methodology (TIG welding) would have required careful welding – and the carefully TIG welded sheets would have suffered from discolouration and distortion from the heat.

Kikukawa overcame this difficulty by combining the latest welding technology and craftsmanship.

The welded and finished brass sheets. Originally 1230mm (W) x 2500mm (L) sheet and 500mm (W) x 2500mm (L).

The result is a flat perforated metal sheet, over the market available sheet size, without visible welding marks.

As shown, Kikukawa combines the latest welding technology, such as laser welding, to the classics, such as TIG welding, and craftsmanship to implement various metal crafting needs.

For more information on Kikukawa’s TIG welding, click here

For more information on Kikukawa’s welding technology, click here