January 26, 2021

Cylindrical Bronze Tsuchime (Hammertone) Lampshade

Kikukawa is most known for its ability to apply high-standard and complex metalworking from design to implementation. However, our expertise extends to applications of bespoke finishes in addition to the shaping or dual curving of the product.

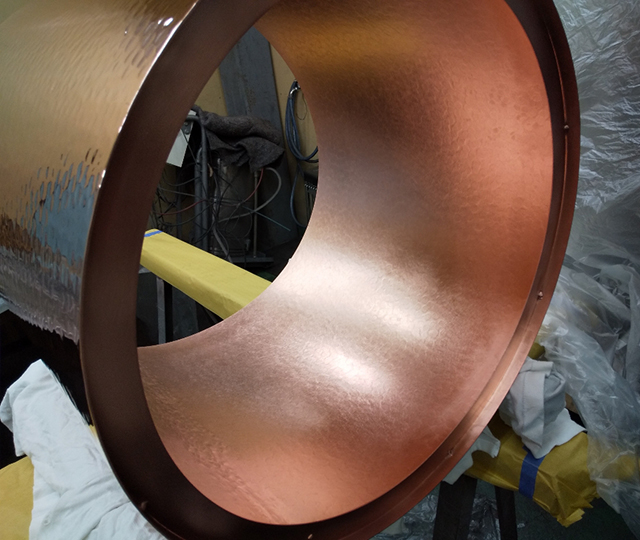

An example of this is the bronze Tsuchime (hammertone) lampshade installed within a shop in Yokohama. The nine copper lampshades are the central piece to this space, delivering warm gentle light to the room.

In this space, there are seven φ540mm by 490mm high bronze hoods, and two φ540mm by 590mm high bronze hoods, fabricated and installed by Kikukawa.

The design intent was to create ‘warm antique textures with bronze Tsuchime (hammertone) patterning’. Through various sample finishes, the intent materialized into the current glossy clear coated Tsuchime (hammertone) finish, TM-2*.

*Click here to check out TM-2, one of our standard Tsuchime pattern finishes

On a 1.5mm copper sheet, Tsuchime (hammertone) was patterned using Kikukawa’s proprietary technology, then R curved into a pipe then welded to create the cylinder. As any metalworking process after the patterning process interferes with the pattern, Kikukawa’s expertise and craftsmanship were required to pattern and weld the piece into the high-standard product required.

This was made possible by obtaining different approved samples for the welding quality, colour of the product, and patterning, each implemented under Kikukawa’s strict quality control. While the timeline for fabrication was limited, these measures resulted in a high evaluation from our client.

Given the current social situation, this project started and concluded without any face-to-face meeting with the client. Based on e-mail, online meetings or phone-calls, Kikukawa’s experts are able to consult and provide a high standard product from design to installation.

From complex projects to bespoke finishes or feasibility, please consult Kikukawa’s representative to implement your design intent.

Click here to learn more about Kikukawa’s proprietary Tsuchime (hammertone) technology

Click here to learn more about another project with Tsuchime (hammertone) pattern