Mirror Finish

Bespoke Tsuchime (hammered) patterns, sizes, depth and pitch accommodated

Tsuchime (hammered) finish, or Tsuchime pattern, is a traditional Japanese artisanal finish, fabricated by hammering the metal sheet one pattern at a time. The Tsuchime pattern varies depending on the size, pattern, depth, and the pitch of the pattern.

Tsuchime is favored for various uses from monuments to architectural interior constructions, to accessories and cooking utensils. In architecture, the aesthetically versatile artistic texture creates a space that is interesting; it transforms a space into rustic, industrial, classic, contemporary or cozy depending on the hammering pattern.

Kikukawa has elevated this classic artisanal finish with its proprietary technology to apply the patterns in a more efficient manner while maintaining the artisanal taste. This newly developed technology reduces cost, and lead-time while also allowing greater freedom in patterns and workable sheet sizes and products.

Kikukawa’s Tsuchime is applicable to copper and aluminium, and the maximum workable size is 1200mm(W) by 2500mm(L).

| Main Features | ・High-quality artisanal Tsuchime (hammered) architectural products available with years of experience and QC know-how ・Bespoke Tsuchime (hammered) patterns, sizes, depth and pitch accommodated ・Metalworking the Tsuchime (hammered) sheets accommodated ・Bespoke finishes in combination with Tsuchime (hammered) accommodated |

|---|---|

| Applicable Materials | Metal ・Copper ・Aluminium Other metals available upon request |

| Maximum Workable Size | Maximum 1200mm (W) × 2500mm (L) Please consult us for any products over this size |

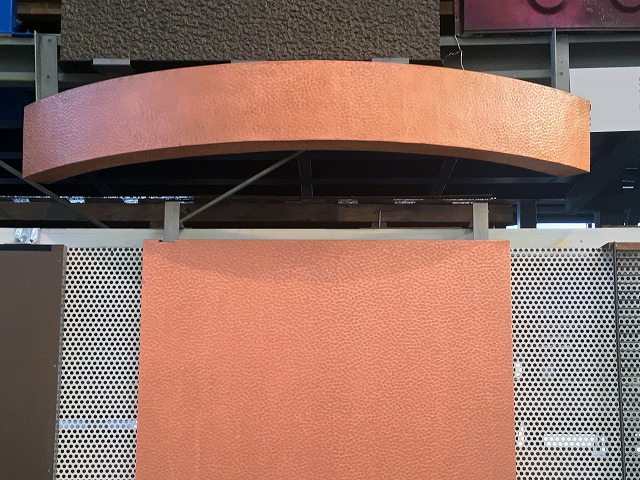

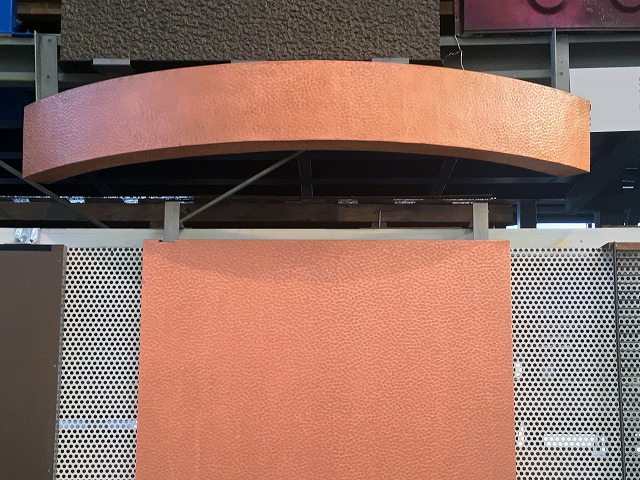

Tokyo Kaikan's Tsuchime finished double curved panel

■Tsuchime (hammered) finish

Tsuchime (hammered) is a textural patterning technique that is achieved by hammering sheets with a tool, one pattern at a time. The Tsuchime (hammered) pattern varies depending on the hammering tool’s size, pattern, material, type and the artisan’s working space and his/her strength.

Tsuchime (hammered) is favoured for its aesthetics, as well as its versatility. Typically as a design focal point, the texture is used in various ways, including monuments, interiors, interior constructions such as walls and ceilings, accessories and cooking utensils.

Small Tsuchime (hammered) tones create a classic and delicate tone within a space, while the larger Tsuchime (hammered) patterns add an accent to the surrounding space.

■Producing the Tsuchime (hammered) pattern

Traditionally, Tsuchime patterns were produced by hammering one texture at a time. Therefore, the Tsuchime pattern and the resulting texture, production speed and quality depended on the skill and experience of the craftsman.

To apply the Tsuchime (hammered) finish, in an (inconsistent yet consistent) artisanal way, skilled craftsmen and expertise are required in each of the Tsuchime patterning steps. That is, (annealing) preparing the metal sheets, the selection of the tools (hammers or the hammering platform), and the quality control know-how to create consistency in the pattern and in removing distortion from the metal sheets as it is hammered.

Consider the selection of the hammering tool, for instance. To apply the patterns, hammers with rounded tips (karakami) are used, while shaping the work piece would require the “Imo” hammer, and embossing would require “Otafuku” hammer. For additional texture, such as striped patterns, bespoke “Arashi” hammers with patterned tips would be used.

In recent years, ready-made hammered products are also fabricated with die-casting, machine embossing, and through hammertone paint; expanding the design feasibilities and manufacturing options for various products.

However, each methodology has varying limitations in cost, pattern and workable sizes. Therefore, double-checking the requirements and limitations prior to your final selection is necessary.

■KIKUKAWA’s Tsuchime finish

Traditionally, Tsuchime finish was applied piece by piece by an experienced craftsman. Thus, the resulting quality of the pattern, the production speed and cost depended on the craftsman’s expertise and know-how. With other fabrication methodologies such as die-casting or machine embossing, limitations such as workable sheet sizes, feasible patterns, fabrication lead-time, or cost such as the fabrication of casting die existed.

Kikukawa developed its proprietary fabrication methodology that produces Tsuchime patterns more efficiently. Kikukawa’s Tsuchime (hammered) allows greater design options in pattern and workable sizes, while maintaining the traditional artisanal physique.

For additional touches to the Tsuchime (hammered) patterns, bronze alloys could be polished or FURUMI (sulufrized) and clear-coated, and aluminium could be anodized and paint coating.

Kikukawa expands the Tsuchime design options by answering bespoke requests such as variations in patterns, sizes, and textures, or through the combination of finishes. Please contact us for Tsuchime (hammered) finished products of other metals that are not mentioned above.

For more information on FURUMI (sulfurization), click here

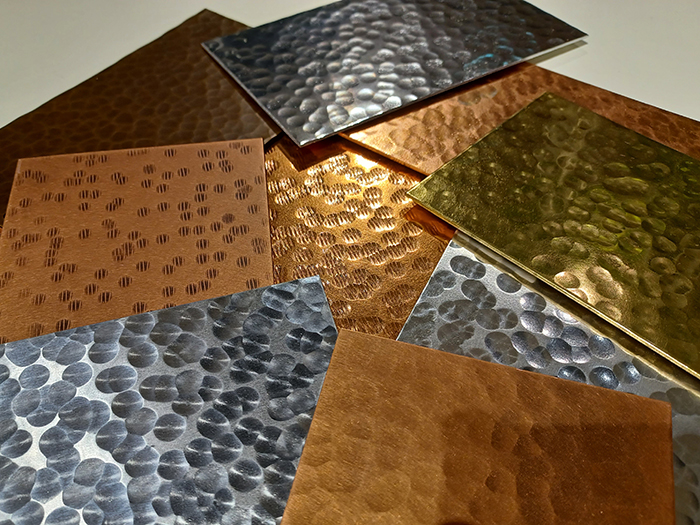

■KIKUKAWA’s Tsuchime sample book

Kikukawa’s Tsuchime sample book features eight selected patterns of Tsuchime (hammered) finishes to display the versatility of Tsuchime, hammered finishes.

Featured materials are bronze, brass and aluminium, and FURUMI (sulfurized) copper.

Listed Tsuchime (hammered) patterns are as below.

- 1. Standard series (TM)

The most basic pattern: the Tsuchime patterns are placed on top of each other. Sizes of the Tsuchime (hammered) can be adjusted.

- 2. Gap series (TMG)

The series displays the versatility of Tsuchime finish by varying the pitch of the pattern. Placing (pitch) and sizes of the Tsuchime pattern can be adjusted.

- 3. Striped series (TMS)

A Kikukawa original, these are Tsuchime patterns with stripes. Sizes of the Tsuchime and the pitch of the pattern can be adjusted.

To view the Tsuchime sample book, click here

■KIKUKAWA’s Tsuchime (hammered) projects

◆Striped Tsuchime, double-curved

At (the 2nd generation) Tokyo Kaikan’s main building entrance hall built in 1971, Kikukawa’s double-curved metal construction with striped Tsuchime pattern was installed. Unlike the typical Tsuchime patterns, the selected striped Tsuchime require greater expertise in quality control. In addition to the difficulty in patterning, the panels were required to be double curved to line the revolving door.

Our records from the production note that even the most experienced craftsman could only pattern 0.5m2 a day.

Kikukawa’s Tsuchime panel can no longer be seen at Tokyo Kaikan as it was rebuilt from 2017 to 2019. However, the previously installed Tsuchime panel was collected and re-installed at Kikukawa’s factory in Chiba to be viewed.

For more information on Kikukawa’s factory in Chiba, click here

◆Tsuchime patterned double-curved construction with minimal joints

At the entrance of Tokyo Marine & Nichido Building, four revolving doors and six sliding doors are covered with Kikukawa’s polished or Tsuchime patterned panels interchangeably. The panels are fabricated from 1.5mm thick copper; the largest being double-curved 2000mm (H) and 666mm (W). The building, completed in 1973, is one of Kikukawa’s representative Tsuchime project to this day.

◆Bespoke Tsuchime (hammered) finish

An example of Kikukawa’s bespoke Tsuchime finish is a monument within a retail store in Tokyo. The 17m tall cylindrical tube is covered in 121 sheets of 2000mm (H) and 1000mm (W) hammered copper sheets and flower shaped objects.

Each panel and object was patterned with two bespoke hammers of varying sizes.

Kikukawa is able to develop bespoke hammers and create varying shapes as required.

To learn more about the project, click here

■Considerations when using Tsuchime (hammered) finish

・Tsuchime is applied one by one with Kikukawa’s proprietary technology, therefore the pattern may have slight variations. These variations are considered to create the artisanal physique.

・The same Tsuchime (hammered) pattern may vary depending on the hammering material or its thickness, as the resulting depth of the texture may vary.

As such, we ask that a finish sample is confirmed for colour and patterns prior to your final selection to ensure quality control.

■Others

Tsuchime finishing experience is available within Kikukawa’s sample room, Studio K+, in our Chiba factory. Please contact us for details

■Please consult us

A warm and textured artisanal finish -Tsuchime. As a finish that fully utilizes the base materials’ texture and as a bespoke finish, Kikukawa can respond to a wide variety of requests. Please do not hesitate to contact us for more details.

Tokyo Kaikan's Tsuchime finished double curved panel

Large double curved tsuchime panel at Tokyo Marine and Nichido Building

Large mockup with varying tsuchime patterns

Tsuchime finish experience booth at Studio K plus, within Kikukawa's Chiba factory