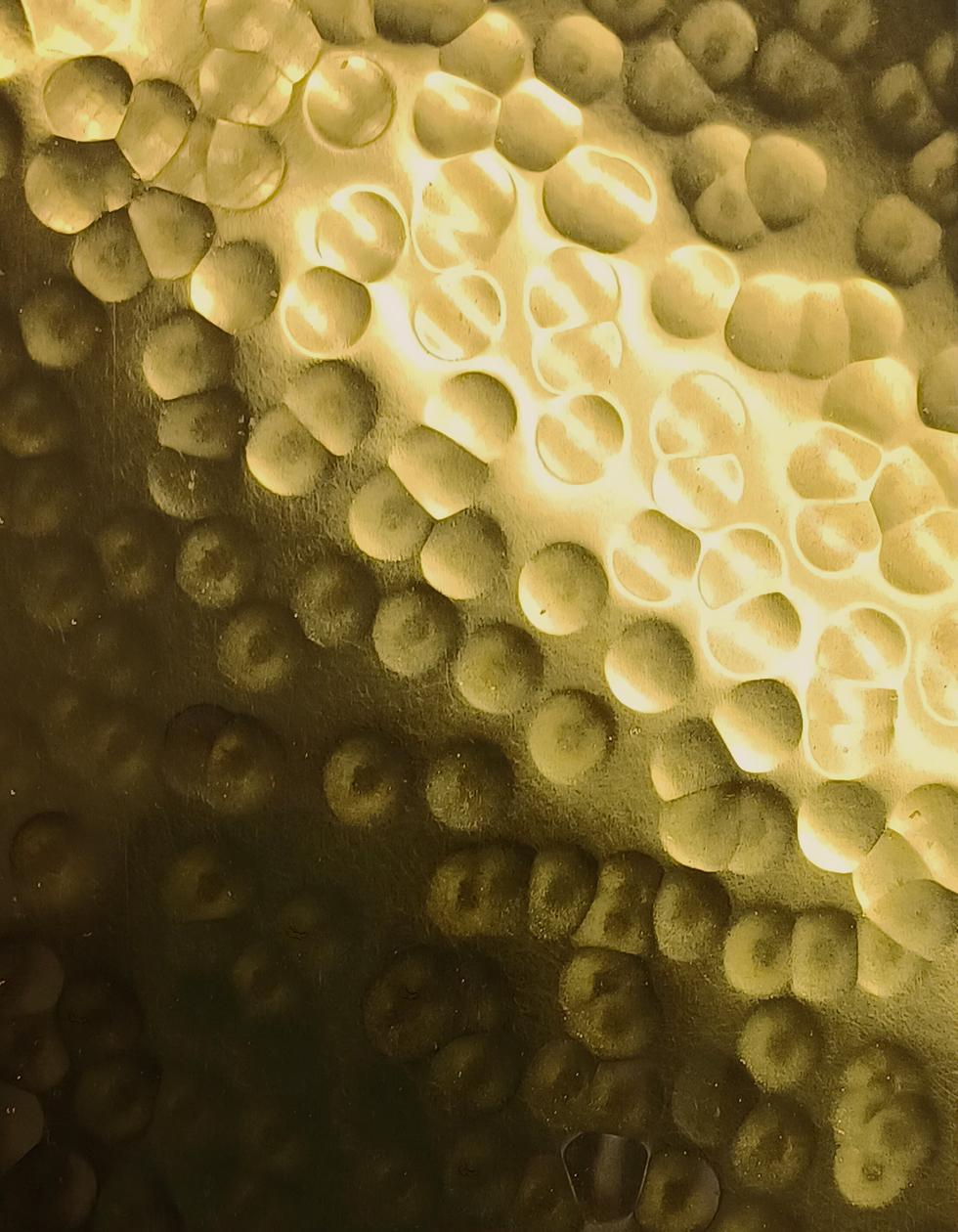

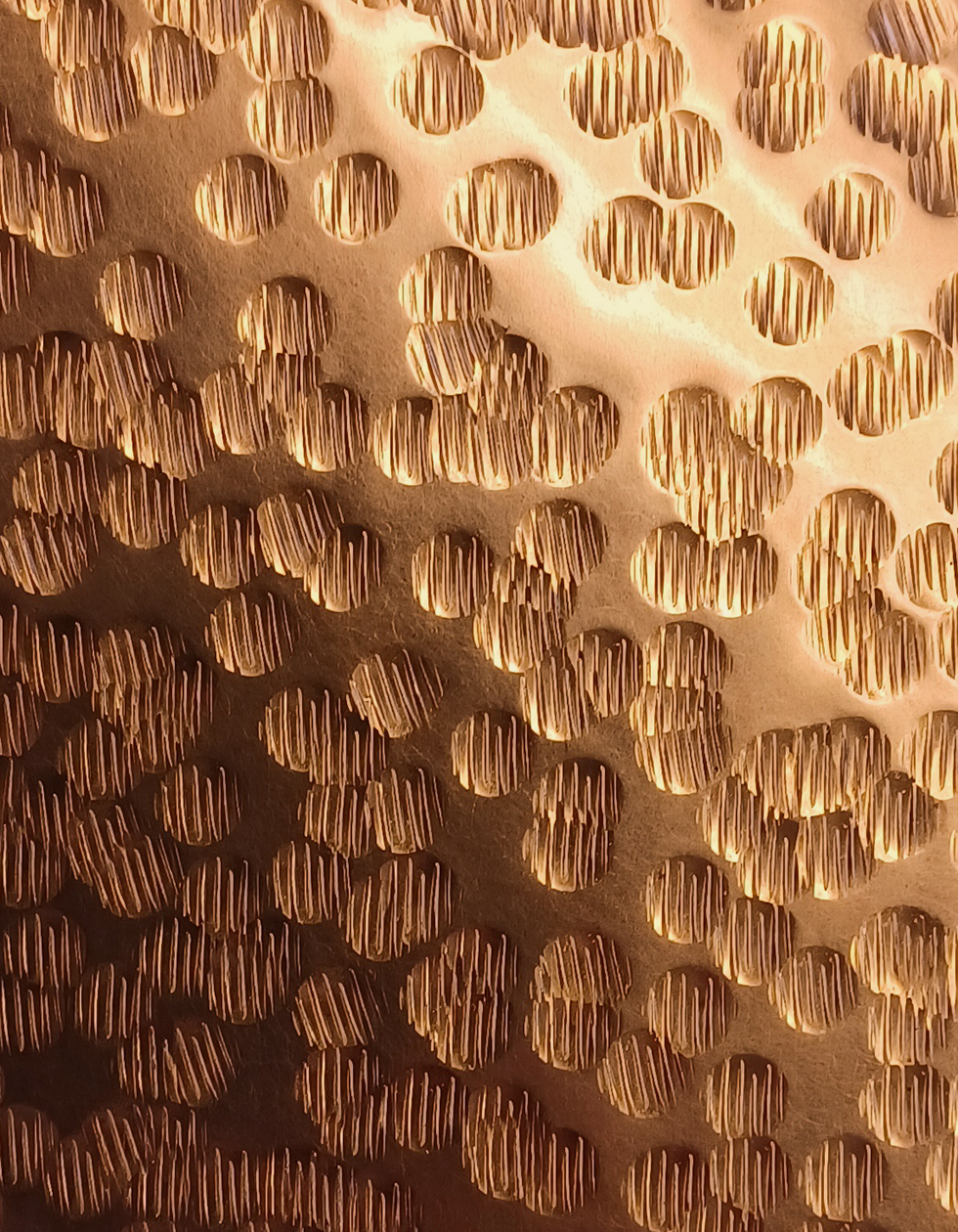

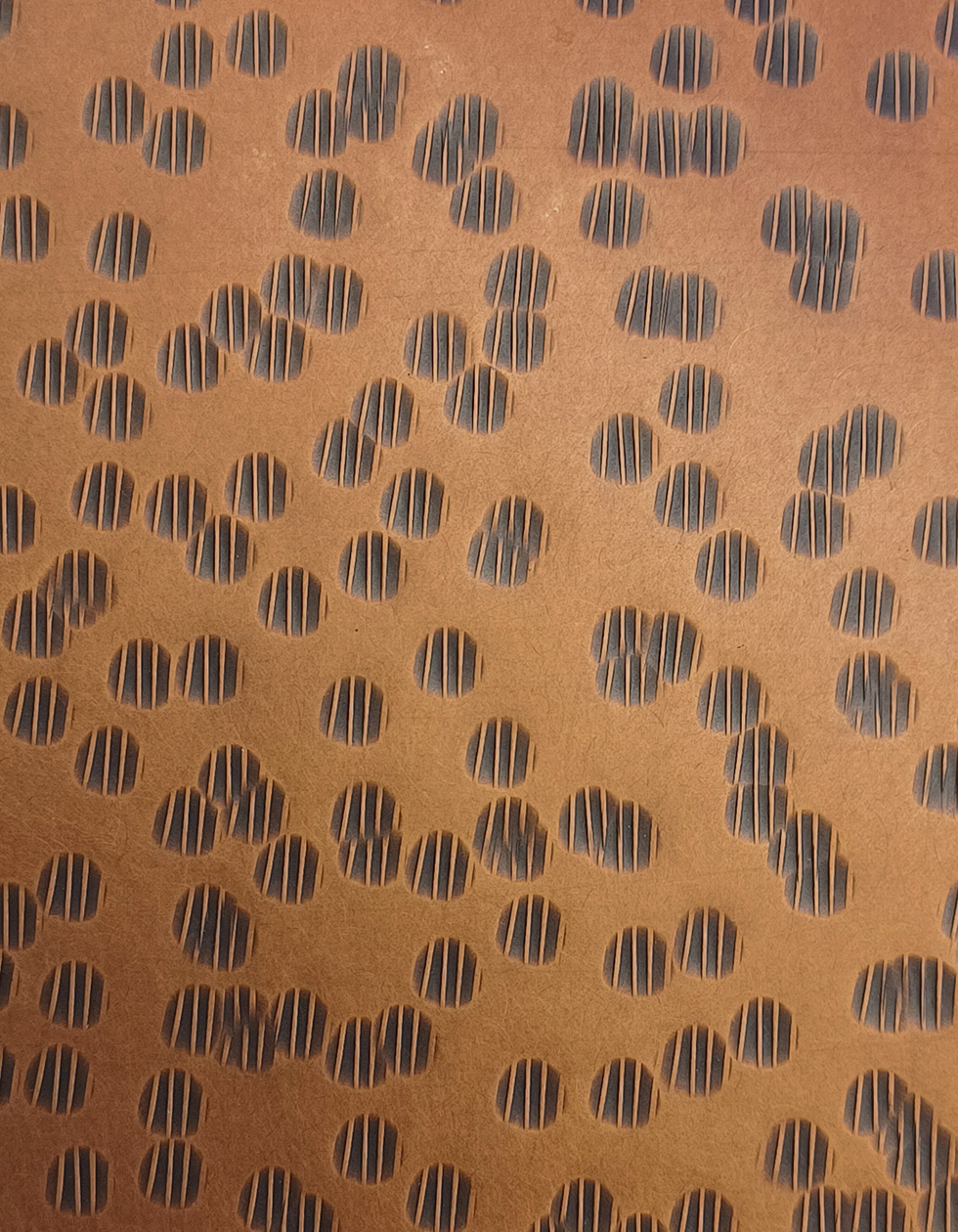

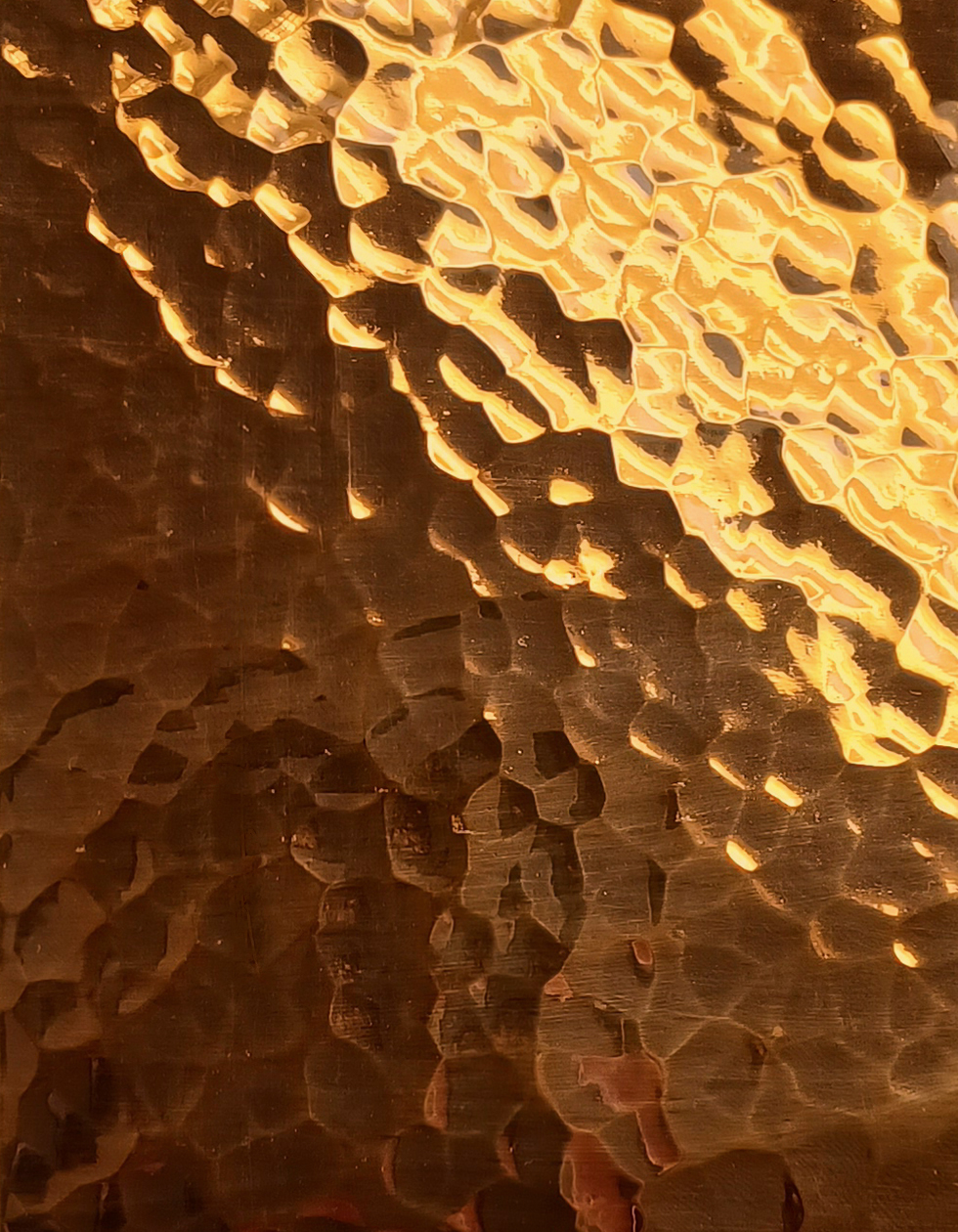

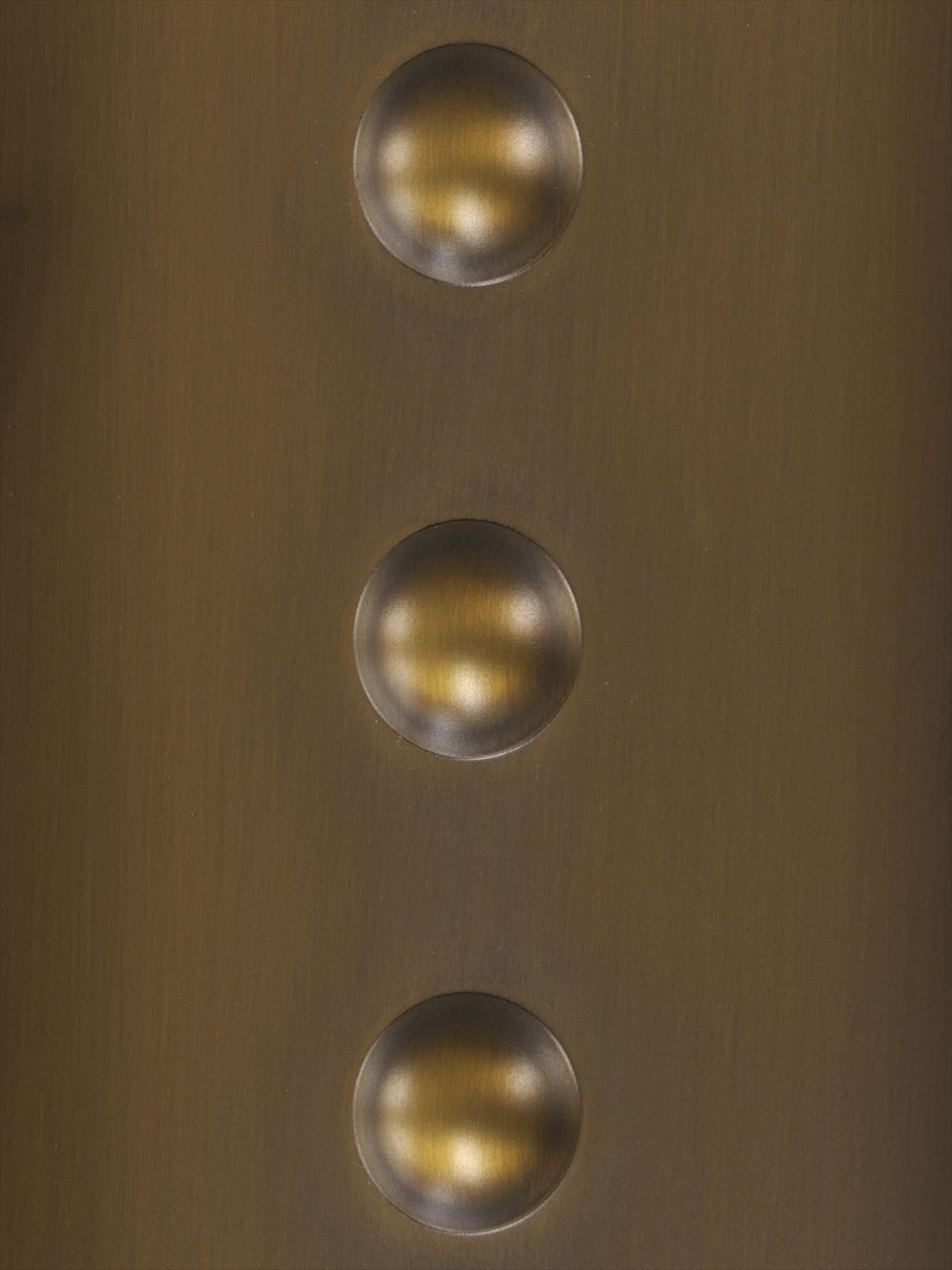

The copper sheet is hammered with Kikukawa's proprietary technology and finished with a coat of clear coating. This finish recreates the classic and luxurious aesthetics of the traditional hammered handcraft finish.

This finish is suitable for signs, frames, ornaments or places that require architectural accents.

Maximum available thickness is 3.0mm, and 1000mm(W) x 2500mm(L) in size.

You could mix and max the material, hammering pattern and finish as required.

*This finish is part of the Tsuchime (hammered) sample book.

The usage of bronze is known to date as far back as 7000years ago based on the artifacts found worldwide.

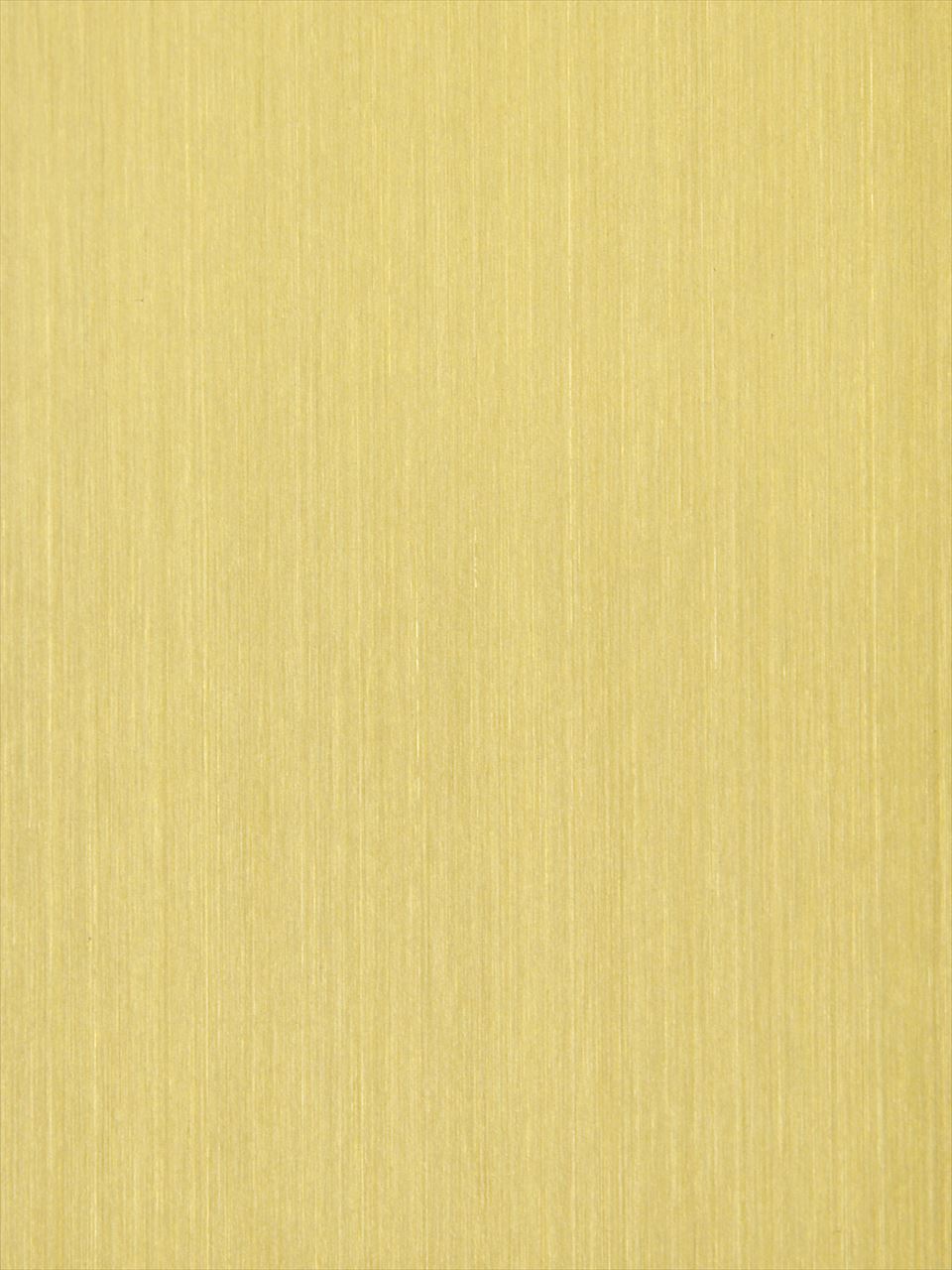

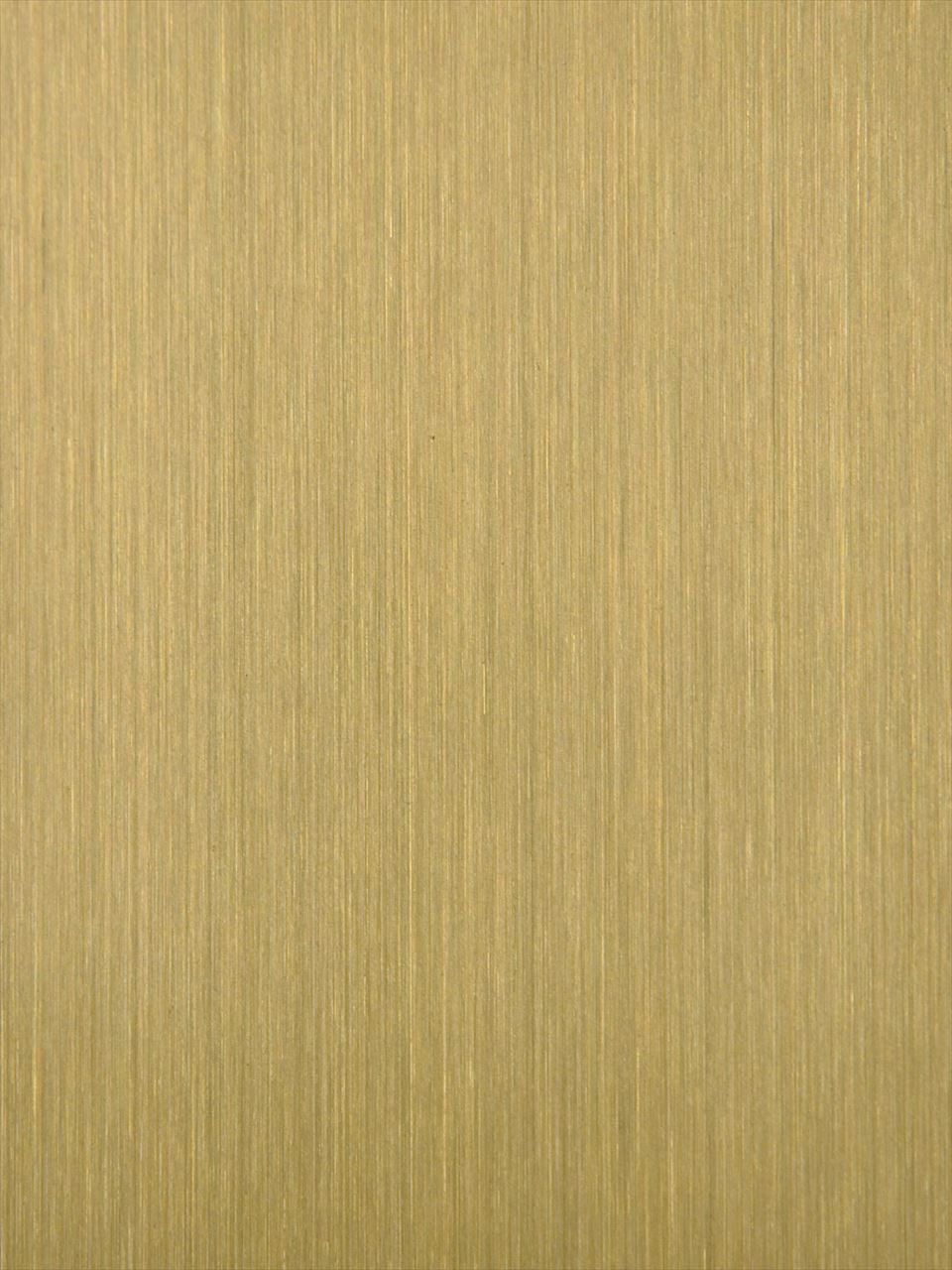

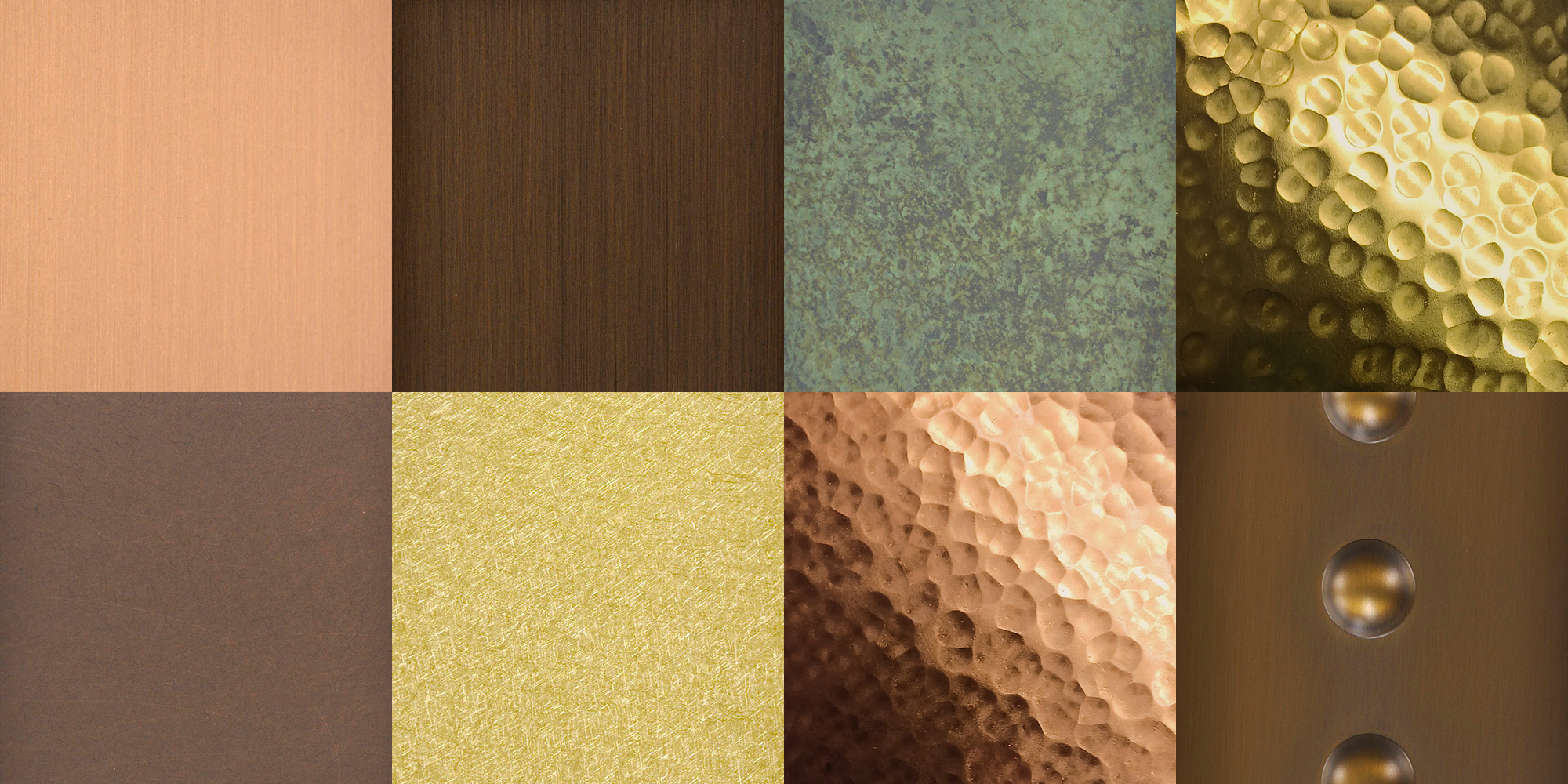

The material, copper, is naturally shiny and pink however the colour varies depending on the chemical compositions of the alloy.

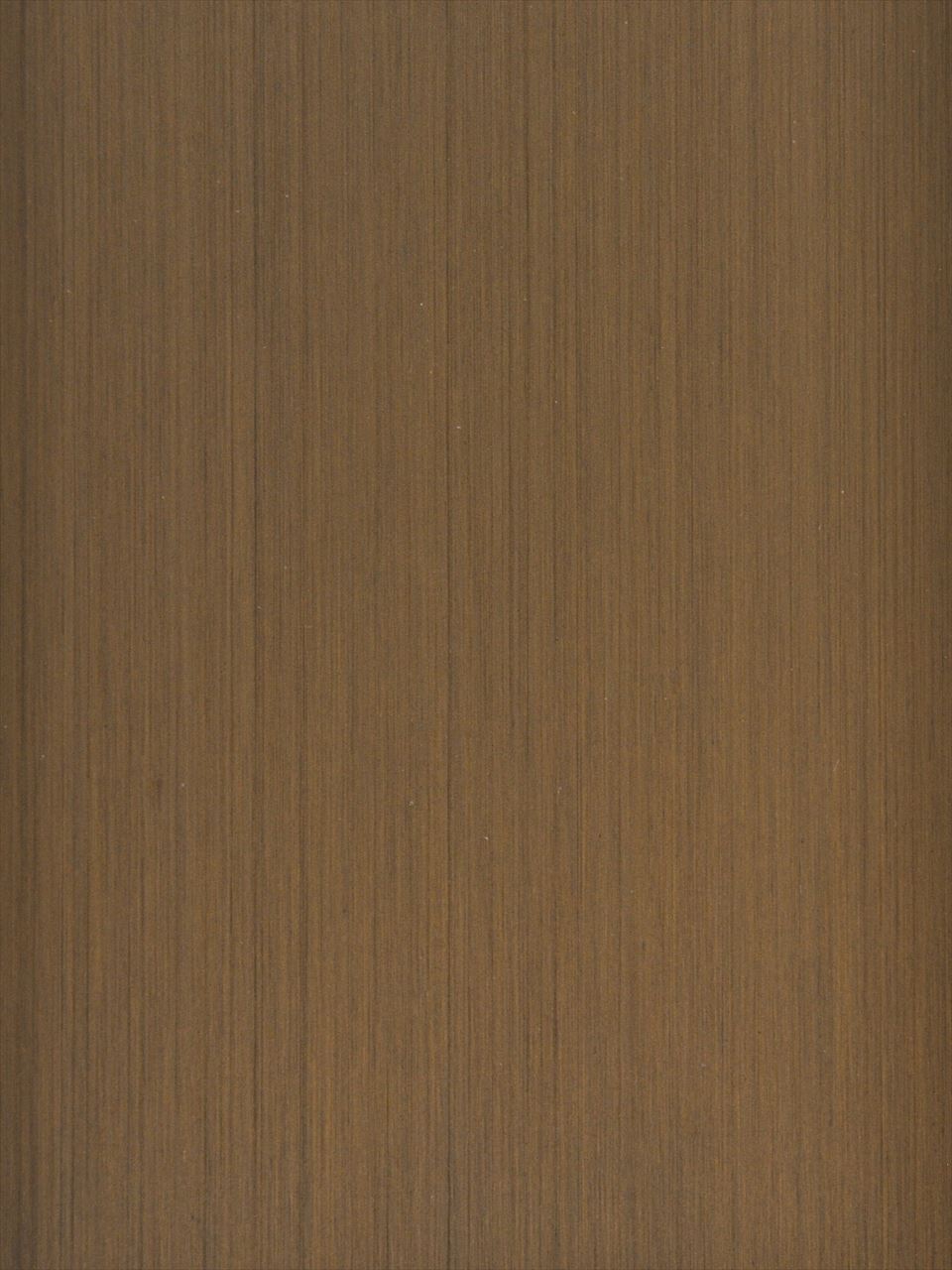

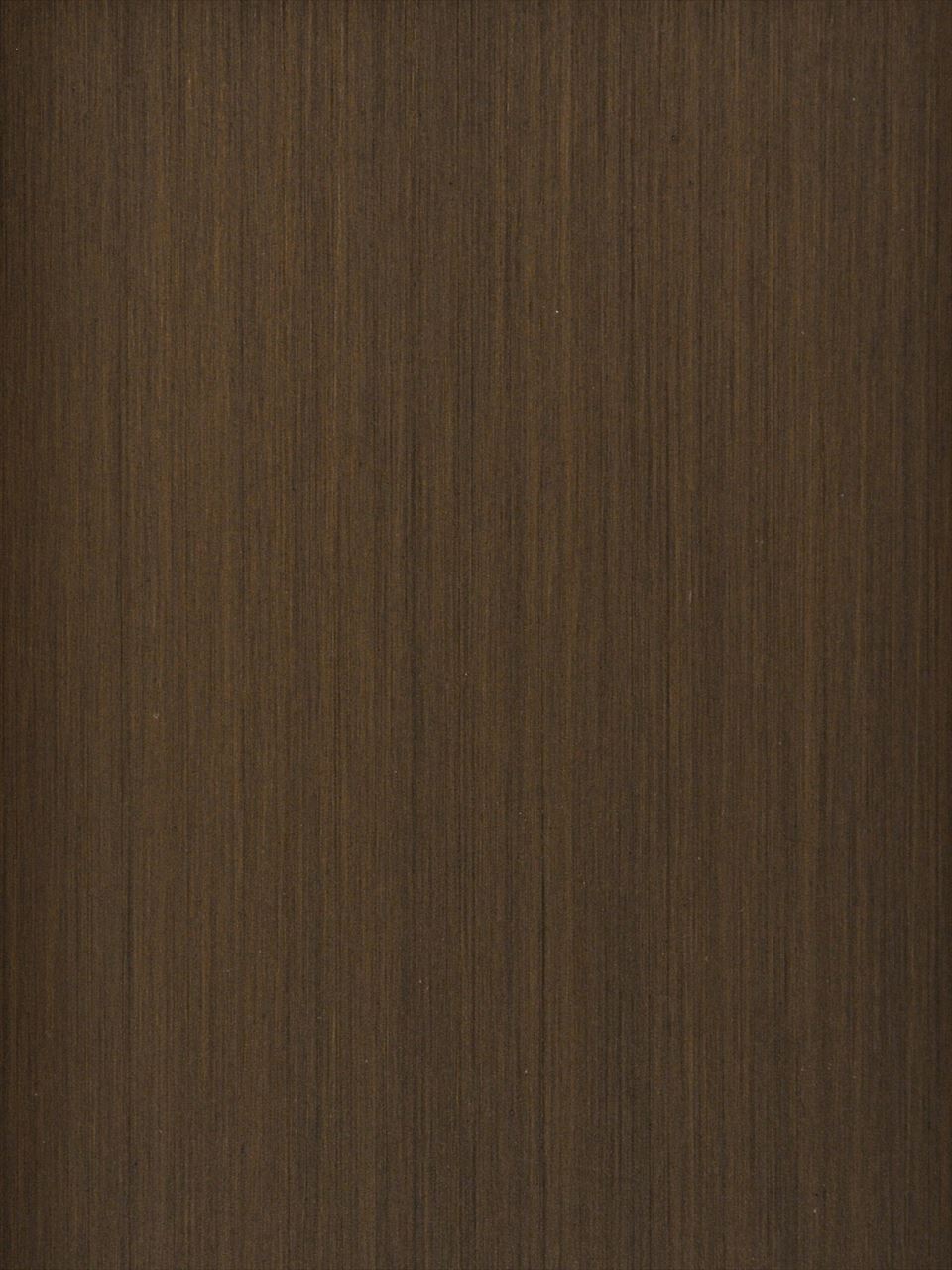

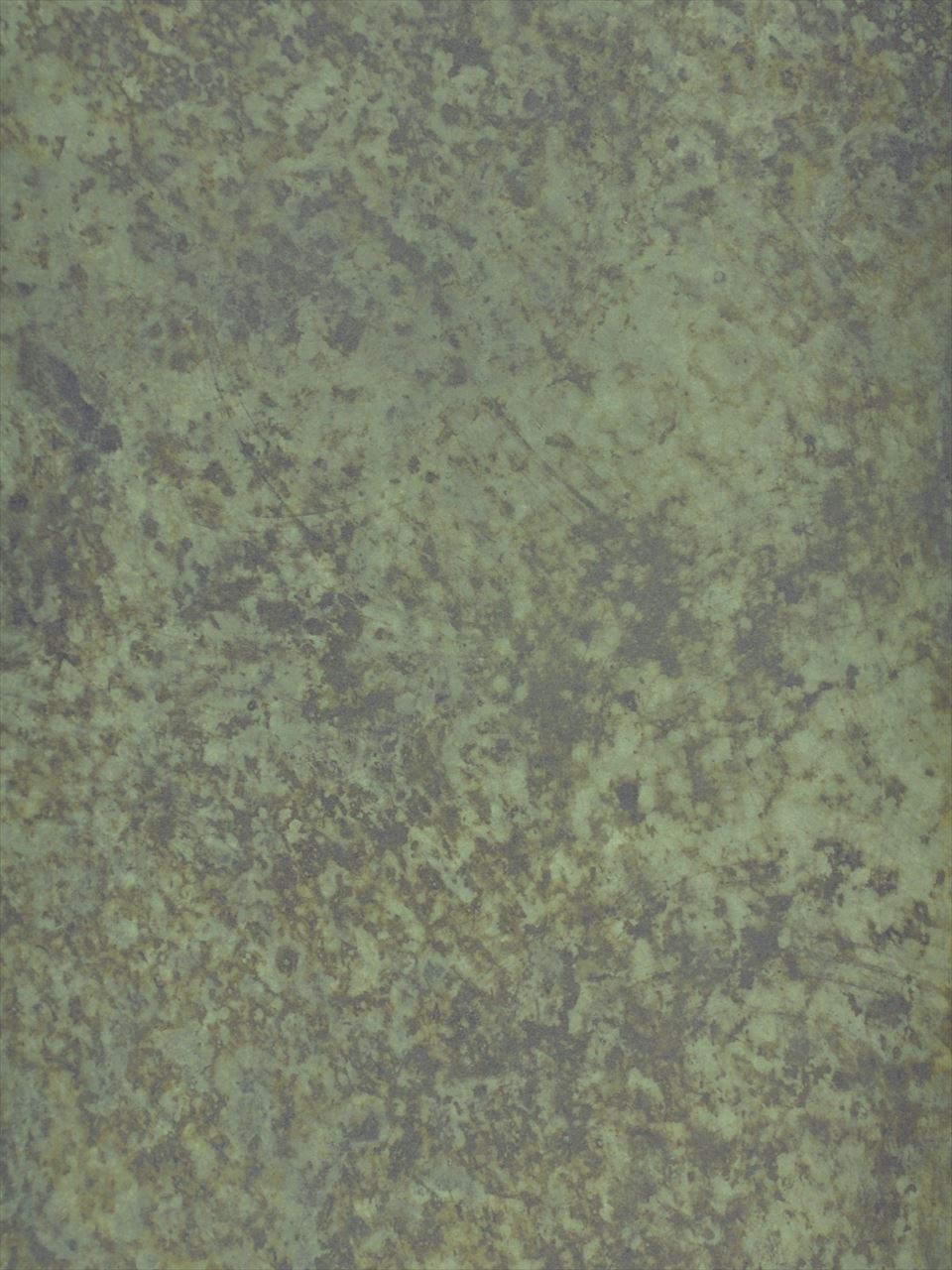

One of the notable properties of bronze is the patina that develops on the surface that protects it from further corrosion. The higher the copper content is, the easier it is to patina and the colour of the patina can vary from blue-green to rich dark brown.

KIKUKAWA provides a wide range of bronze finishes; from those that enhance the beauty of the material to those that recreate the luxurious patina by hand.

*Please note that the photos of the samples are guidelines. Please confirm the finish with an actual sample prior to making your final selection.

Click here to check the contents of KIKUKAWA's Bronze Finish Sample Book