November 10, 2020

Scraped (Etched) Design Aluminium Panel

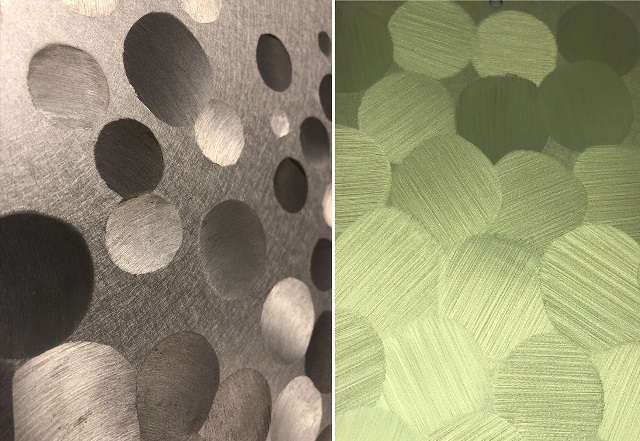

Scraped or etched patterns may be applied to aluminium, stainless steel, and bronze as a way to implement the design intent. Also called the polished or grinded finish, typical finishes include HL, PHL (vibration), and mirror-polished textures. Kikukawa’s metalworking technologies and abilities allow tremendous customization potential for metal surfaces. Pictured below is such an example, the bespoke polka-dot etched finish.

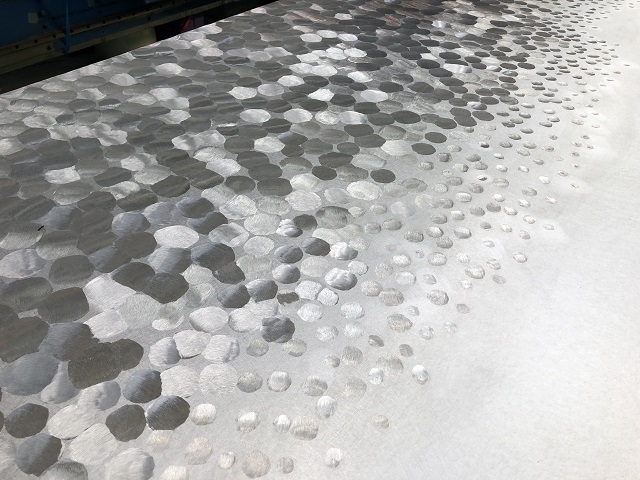

The polka-dot etched finish* is achieved by applying random circular etching to various directions. The size of the pattern, frequency, etching direction, and etching depth can be selected as required.

Pictured is the remodeled Men’s Building of Shinjuku Isetan that opened in March 2019. Kikukawa’s aluminium panels were installed on the 4th floor when the building underwent the first large-scale remodeling in 15 years.

As a department store, the concept of the remodeling was a floor that makes comparative shopping more available. Thus, the new floor layout removed walls between luxury brands – and it divided each space with walls with the names of each brand. This meant that the 15 walls that defined each space were required to create a sophisticated luxurious space that suits the apparel stores within the floor. Kikukawa’s bespoke polka-dot etched finish panels fully contributed to the implementation of this design.

The column panels are fabricated from 5mm vibration (PHL) aluminium sheets, etched with polka-dot patterns as designed then clear coated. Each face is typically 1200mm (W) by 2750mm (H), and the 5mm edges with 2mm thin joints details create a sharp aesthetic.

Kikukawa’s expertise and know-how were fully utilized to faithfully implement the polka-dot patterns of the designer’s sketches. In addition to the QC system, each pattern was carefully placed by our craftsmen.

Polished, grinded, scraped, or etched – Kikukawa is able to provide bespoke or custom patterns as required. From traditional to cutting-edge technologies, Kikukawa selects the most suitable fabrication methodology to achieve the design intent. Please consult us for feasibility or for more information.