June 25, 2019

Water Ripple Stainless Steel

Kikukawa develops its own proprietary technologies as required in order to fulfill the design intent as exemplified by the following examples of bespoke mirror-polished water ripple stainless steel.

In recent years, we have observed the rise in the usage of water ripple (embossed) mirror-polished stainless steel. In response to this, Kikukawa has devised a methodology that would allow us to emboss the high-quality mirror polished stainless steel in selected areas at selected depths, without any damages or scratches.

The installed mirror polished stainless steel + embossed ceiling panels

On the top right corner is the aforementioned ceiling panels, contributing to the creation of a serene space.

The pictured embossed mirror-polished stainless steel represents the disturbances of the water in ripples or waves as designed.

These designed ceiling panels use three 1.0mm thick mirror-polished stainless steel with bent details, sized 900m (W) and 1639mm (H).

Given the beautiful reflective properties of mirror-polished finish, any small dents, scratches or imperfections become accentuated. Thus the higher the quality of the mirror-polish, the more difficult it is to apply any metalworking.

Based on the design data, Kikukawa fabricated a special mold that was rolled together with the stainless steel. By doing so, these panels are metal-crafted to have the desired depth of embossing at the designed location.

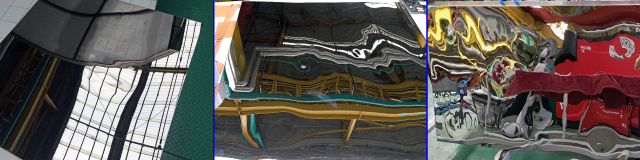

Embossing test pieces. From the left, testing the feasibility, testing the degree of embossing and testing on an outsized piece.

Being a bespoke architectural metalworker, Kikukawa finds solutions to implement architectural designs and constructions. The development of this particular fabrication methodology is an example of this.

For feasibility on embossing, product shape or combination with other metal finishes, please consult us.

To see more pictures of the mirror-polished water ripple stainless steel project, click here

To view Kikukawa’s projects with high-quality mirror-polished stainless steel, click here