Sukyo Mahikari Headquarters shines gold from the vast amount of bronze

Hairline, polished and clear coated bronze cover the ridgepole (munagi), gable (hafu), and the lattice grid

Hairline, polished and clear coated bronze cover the ridgepole (munagi), gable (hafu), and the lattice grid

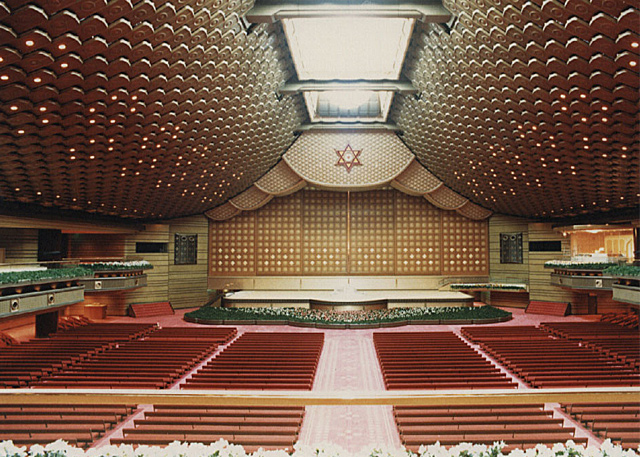

Within the great shrine. Pictured are the pressed steel ceiling panel and proscenium arch crafted from die-cast aluminium

Within the great shrine. Pictured are the pressed steel ceiling panel and proscenium arch crafted from die-cast aluminium

■The Golden Religious Architecture

The golden architecture of Sukyo Mahikari, World Headquarters lies within the mountains of Takayama, Gifu prefecture, in a vast space of roughly 14,000㎡. Kikukawa was involved in the metal construction of this project.

Kikukawa’s main contributions are in the ridgepole (munagi) and gable (hafu), which uses a vast amount of bronze material. As a religious architecture and as a bronze construction, the scale of this architecture is one of the largest in Japan.

■Maximizing the Texture of the Bronze Material

Since the ridgepole is over 5m above the ground, the ridgepole cover panels are crafted from hairline finished and colour clear coated bronze to prevent discolouration from sulfurization and to maximize the texture of the material.

The crest panel, interior and exterior frames, corrugated transom, and screening panels are each crafted to create a gentle curvature. Craftsmanship was specially required for the interior frames surrounding the corrugated transom, crafted by combining 6 pieces of triangular panels, as it joins sharp-edge bent and curved pieces.

The four transom column covers on the side are crafted from 700mm wide concave bronze panels with a die-cast bronze decorative piece on its centre. The protruding areas and the die-cast panels were buff polished then clear coated.

The tip of the ridgepole and its sides consist of buff polished bronze and bronze die-cast. The shrine crest is crafted from gold gilded moulded FRP (fibre reinforced plastic).

■Symbolic Sphere (Munedama) Crafted from Metal

The 1850mm radius aluminium die-cast sphere, munedama, sits on top of the roof. This symbolic smooth and bright vermilion sphere is finished with powder-paint coating and film lamination.

The lotus valve (renben), lotus seat (renza), pedestal, and pedestal transoms are crafted from bronze. The lotus seat and pedestals are mostly crafted from hairline finished bronze, and the decorations are buff polished bronze casting. The pedestal transoms are textured with Rough-tone, then buff polished.

The lotus valve pedestal that stretches 4meters from its center, stacked in 3 layers is crafted from 46 pieces of 13 types of die-cast bronze for the three-dimensionality.

Click here to learn more about Kikukawa’s Rough tone

■Contrasting the Various Bronze Finishes (Polished, Hairline, FURUMI Sulfurization)

The gable border panel and the soffit panel that meets the roof panels are roughly 10m on one side and are crafted from hairline finished bronze. Including the lattice frame, the fabrication of variously shaped dual-curved panels required Kikukawa’s know-how and craftsmanship.

The lattice grid crafted from 300mm wide pentagon panels placed at 400mm pitch is hairline finished and clear coated bronze. The joint panel is hairline finished and FURUMI (sulfurized), contrasting from the buff finished lattice frame and drain panel.

The crest placed at the centre of the lattice grid was also crafted from gold gilded moulded FRP (fibre reinforced plastic).

Click here to find out more about Kikukawa’s Bronze finish samples

Click here to find out more about Kikukawa ‘s FURUMI (sulfurization) technology

■The Majestic Ceiling Panel of the Great Shrine, Dai-Haiden

Within the great shrine, Dai-Haiden, the ceiling panels curve upwards towards the centre. Crafted from over 2000 pieces of standard dimension 985mm wide, 1530mm long, 100mm high moulded panels. Panels with complex shapes were crafted by using large-scale moulding pressed 1mm steel plates, and bespoke paint coating. These scale-like designed panels contribute to the creation of a majestic and extraordinary space.

The 8m long beam panels are crafted by combining aluminium Rough tone and aluminium die-cast, then finished with acrylic paint coating.

The 1420mm high ceiling space is split in three and adds an accent to this space by placing the textured die-cast piece in the centre.

■Gold Coloured Die-cast Aluminium

The 40m wide proscenium arch sits at the top centre of the front stage. Crafted with the fan-shaped aluminium cast in a wave pattern known as seigaiha, which literally translates to blue ocean wave. The 750mm wide, 450mm high gold-coloured panels are placed in a staggered arrangement, wrapped in aluminium cast borders with metalworked edges to create the 7 sets of arches.

The visible back panel of the arches are crafted from steel in a louvre form by placing the 130mm diameter semicircles along the curved edges.

The 3120mm wide, 3600mm high crest consists of box-bent straight panels and drawn circular pieces. The edges and the circular pieces are gold-gilded, and the grey or gold straight pieces are placed in the centre.

Perforated steel sound absorbing panels surround the great shrine from the edges of the stage. Designed with 50mm slits, the perforation is 9mm diameter circles placed at 15mm pitch.

■Kikukawa’s Ability to Accommodate Religious Architecture

Kikukawa’s participation in this project is not limited to the metal construction listed above.

For the exterior, our services extend to the detailed design, fabrication and installation of the steel outer fence finished in phenol resin paint, cap pieces crafted from bronze, aluminium, stainless steel, die-cast aluminium, and die-cast aluminium cap panels between the pre-cast concrete exterior walls. Within the building, our work includes decorative fitting crafted from bronze and steel, ribbed round columns crafted from bent wave-shaped steel, offertory box crafted from bronze plates and casting. Other products extend to die-cast aluminium cast grids are placed within and outside of the building, and more.

The metal construction of Sukyo Mahikari Headquarters required expertise and know-how that Kikukawa has accumulated over the years through participating in various religious or traditional architectural projects. From detailed design, fabrication to installation, Kikukawa’s comprehensive services are fully showcased through the successful completion of this project.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| Ridgepole (Munagi), Gable (Hafu), Lattice Grid | Bronze Die-cast Bronze |

HL + Clear Coating Polished + Clear Coating Sulfurization |

| Sphere (Munedama), Lotus Valve (Renben) | Die-cast Aluminium Bronze Die-cast Bronze |

Powder Paint Coating + Film Lamination HL + Clear Coating Polished + Clear Coating Rought tone (R series) |

| Great shrine (Dai-Haiden) Ceiling: Ceiling Panels Proscenium Arch Perforated Sound Absorbing Panel |

Steel Die-cast Aluminium |

Large-scale Moulding Press Bespoke Special Paint Coating Gold Coloured Paint Coat |

| Project | Sukyo Mahikari, World Headquarters |

|---|---|

| Client | Sukyo Mahikari |

| Architect | Saburo Shiraki |

| Contractor | Joint Venture of Obayashi Corporation and Kaneko Industry |

| Completion | 1984 |

| Location | Takayama City, Gifu Prefecture |