November 27, 2018

A Case of 3D Design

Amongst the various construction materials, metal is considered as most flexible and workable. To maximize and translate these benefits into architectural metalwork, one of the necessary expertise is in design. Metal construction detail designers are required to have extensive knowledge; from the various building parts to the details of each, as well as the characteristics of each metal.

In addition to the expertise, Kikukawa’s design team is strengthening its 3D design capabilities and accommodations.

This arch is an example of such a case. Kikukawa contributed to this project, where various architects and contractors and fabricators communicated and adjusted design, fabrication, and installation based on a single 3D model. The crafted arch showcases Kikukawa’s metal-craft and our capabilities in accommodating the everchanging needs towards BIM.

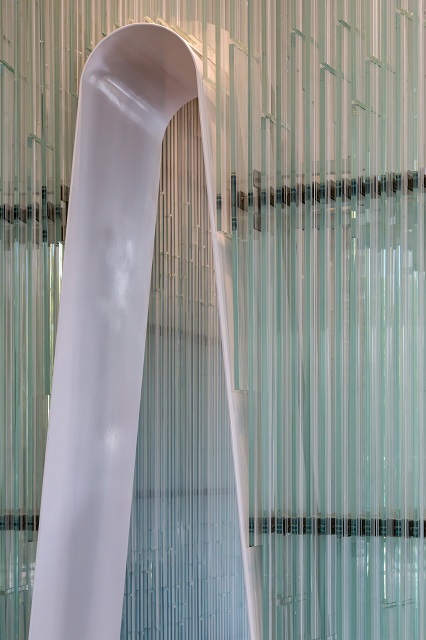

The one-piece steel arch contributes to the making of an elegant space

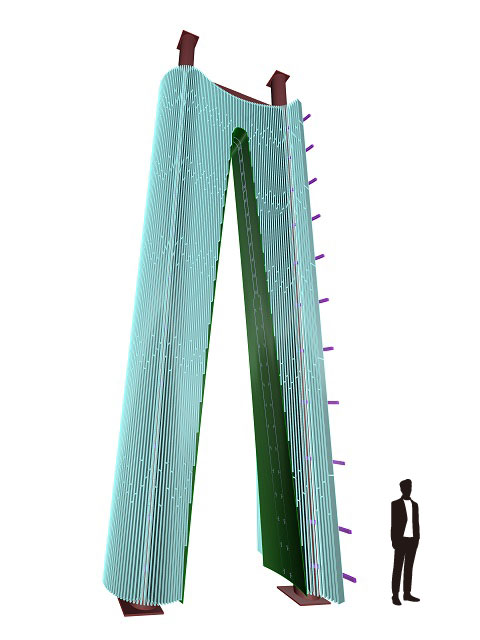

The parabolic arch is made of 4.5mm thick steel.

The 1783mm wide and 7355mm tall arch draws a double-curve; narrowing towards the top and the edges of the panel curling inwards.

The 3D model of a parabolic steel arch and a silhouette of a 170cm tall man.

The actual steel arch

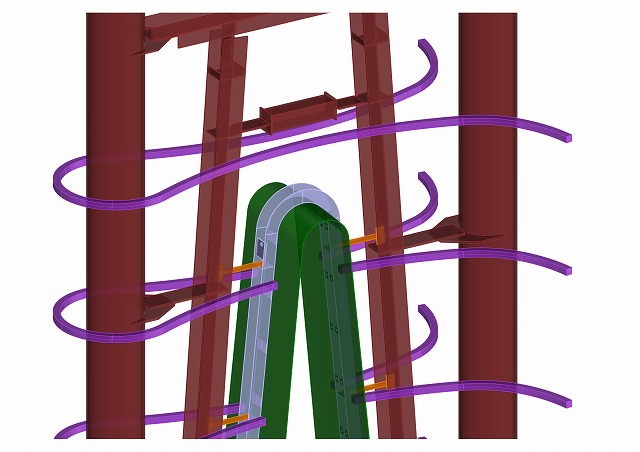

The 3D design of the steel construction is carried out on 3D CAD, based on Kikukawa’s expertise in metal craft. This expertise, for example, is the expansion or the distortion of the metal sheets during metalcraft. To draw designs with considerations to spring-back or minimal expansions of the metal sheets during manufacture, any issue encountered onsite is communicated and shared to the design team.

By repeating this process and accumulating hands-on expertise, Kikukawa has been building its 3D design expertise and know-how.

The connecting areas are checked within the 3D model (steel arch shown in green)

The actual metal piece. The installation was smooth as the details were checked in 3D beforehand.

Behind Kikukawa strengthening its capabilities in 3D design is the spread of BIM, evident in the growing number of cases requiring 3D data and design accommodations.

The benefits of utilizing 3D data include the reduction of lead time for drawing and a smooth installation, as verified in this steel arch case.

Kikukawa will continue to build its expertise in 3D design through metalcraft.

Please contact us for more information on design consultations and design accommodations.

*Click here to learn more about Kikukawa’s 3D processing technology