Placing the Three Dimensionally Processed Panels Together

Kikukawa’s ability to fabricate double-curved products has been refined and solidified over the years. Today, this includes the metal-crafting expertise, and its combination with cutting-edge technology such as FSW (Friction Stir Welding), incremental forming, or fiber laser welding.

Our expertise extends from design to installation – with excellent teamwork, we provide consultation to difficult projects.

| Main Features | -Combination of craftsmanship and cutting-edge technology -Accommodates 3D-CAD -Able to accommodate small lots of a high-variety product lines |

|---|---|

| Name/Type | Machines that accommodate 3D-CAD data -Incremental Forming -3D Machining -Multi-mode fiber laser (welding) -Single-mode fiber laser (cutting) |

| Applicable Materials | -Aluminium -Stainless Steel -Steel -Bronze Alloy Please consult us on other metal sheets |

| Maximum Workable Size | -The fabrication method depends on the material and shape. Contact us for further information. |

Completed in 1997, Dual Curved Soffits Designed With 3D CAD

■Dual Curved Products in Metal Construction

Dual curved metal worked products come in various shapes. Evident examples include spheres or twisted products. Others include a sloping curve or even spiral staircases, which typically have balustrades, handrails, borders and cap pieces that require dual curving. Interestingly, spiral staircases tend to require the highest expertise in fabrication technology. Or border eaves, with a circular cross-section, that runs along a curvilinear building requires dual curving fabrication.

These shapes are often required from metal, is one of the most workable materials amongst the building materials.

With the spread of 3D-CADs, there are increasing numbers of inspired designs that take on complex shapes. As inspired designs tend to be asked of iconic buildings or monuments, the role of metalworking dual-curved products is meaningful within the architecture industry.

■Crafting Dual Curved Products

Typically, metal-craft came in the form of hammering, heating or joining the material. From this basis, Kikukawa’s metalworking technology developed by being involved in various projects. These experience and expertise allow Kikukawa to select the most suitable fabrication methodology – and with our approach to taking on our customer request seriously, Kikukawa has refined the metalworking knowledge to its own.

An example of this is The Dinosaur Egg of Chukyo Campus, which relied on craftsmanship and welding technology, and combining the pieces for a smooth egg-like curvature.

Click here for more information on The Dinosaur Egg of Chukyo Campus

■From Design to Installation

Through various projects, Kikukawa has built its expertise on dual-curved fabrication design. Starting from the introduction of 3D-CADs in the 1990s for the spherical observation room of Fuji Television Network, we have been utilizing 3D-modeling for various rendering and considerations.

Today, Kikukawa is active in the accommodation of BIM and the adoption of 3D-CAD. Bloomberg is an example of its training initiative, as all of the fabrication design was communicated with 3D renderings and data.

Click here for more information on Spherical Observation Room, Fuji Television Network

Click here for more information on Bloomberg’s European Headquarters

■Examples of Dual Curving Technologies and Craftsmanship

Here are some examples of Kikukawa’s dual-curve metal-working technology and craftsmanship. By combining this with our metal-crafting expertise, Kikukawa has overcome various challenges to make high-quality products, efficiently.

◇Incremental Forming

This is a dieless metalworking process that relies on the progression of localized deformation. This technology is able to realise shapes that are difficult with spinning or die casting.

Click here to find out more about Incremental Forming

◇Machining Process

With a head that moves in X, Y and Z axis, this machining process is able to fabricate three-dimensional curvatures.

Click here to find out more about the Machining process

◇Multi-mode Fiber Laser Welding

Actualises a small bead, minimally deformed welding in three dimensions.

Click here to find out more about Fiber Laser Welding

◇Single-mode Fiber Laser Cutting

Kikukawa is able to laser cut in three dimensions. As the machine’s movement is based on design data, it is high in quality and precision.

◇Stretch Forming

Here is a technology that allows the bending of complex shapes without welding. Allows curved products to be bent in another axis.

Click here for more information on Stretch Forming

◇Twisting

Twisting refers to shapes with edges that are twisted in two opposing directions. Actualising this with a single panel is challenging, thus often actualized by joining two pieces. At Kikukawa, twisting is a metal-crafting methodology that was solidified by overcoming these challenges.

■Developing Dual-Curving Methodologies and Technologies

With the widespread use of 3D CAD designs, and the introduction of BIM, the demand to fabricate dual-curved pieces will continue to increase.

To respond to this, Kikukawa is working on developing a new technology that would allow the partial automation of dual-curve metal-working processes.

■Providing a Comprehensive Solution

Without minimal lots, casting or extruding is well suited for dual-curved fabrications. However, this is rare and it limits workable sizes and shapes.

At Kikukawa, we accommodate small lot productions of high variety products. The products’ final shapes and sizes, as well as costs, are considered to accommodate as much of the client’s needs as possible. Additionally, Kikukawa oversees the quality of the product, which ensures precise joints and smooth curvatures.

An example of this is MIHO chapel of MIHO art school – a façade built with 18.5m long stainless steel placed one next to another, each with a unique twisted geometry.

For more information on MIHO Art School, MIHO Chapel

■Please Consult Us

Kikukawa fabricates innovative works with its metal-craft and is continuously doing so by honing its technologies. With our philosophy to “never say no”, Kikukawa continues to challenge itself to realise various design intents.

For information or consultation of complex designs, please contact us.

Completed in 1997, Dual Curved Soffits Designed With 3D CAD

Dual Curved Panel Actualised with Incremental Forming and Craftsmanship

A Panel with a Sloping Dual Curvature

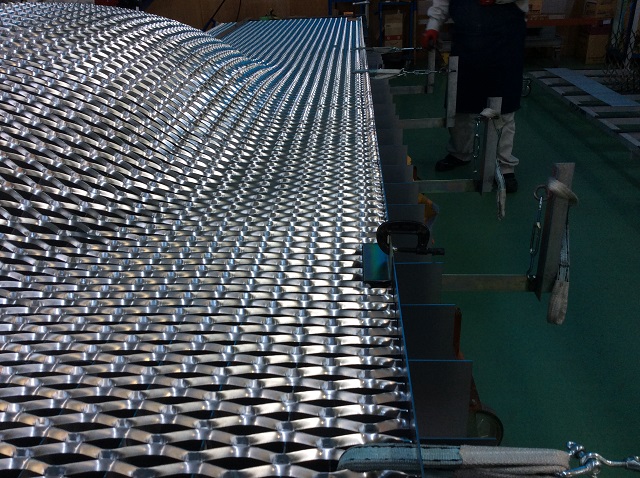

Processing Expanded Metal into a Dual Curved Pocket