FOAM: A Wall Inspired by Bubbles, Fabricated from Welded Steel Round Bars

Bespoke Panels Fabricated from Bespoke Brass Sheets.

Bespoke Panels Fabricated from Bespoke Brass Sheets.

Top & Centre Right: 3F Main Lobby, 6mm Joint Panels.

Center Left: 4F Information Room, Bottom Half of the Panels Installed in the Open Ceiling Space are extra-long 6.8m panels.

Bottom Left: 3F Lecture Room, Glass Partition Fittings and Brass Panels at the Back

Bottom Right: 5F Elevator Hall, Brass Handrails and Brass Panels

Zinc Phosphate Coated Steel Panels with Dark Hues

Zinc Phosphate Coated Steel Panels with Dark Hues

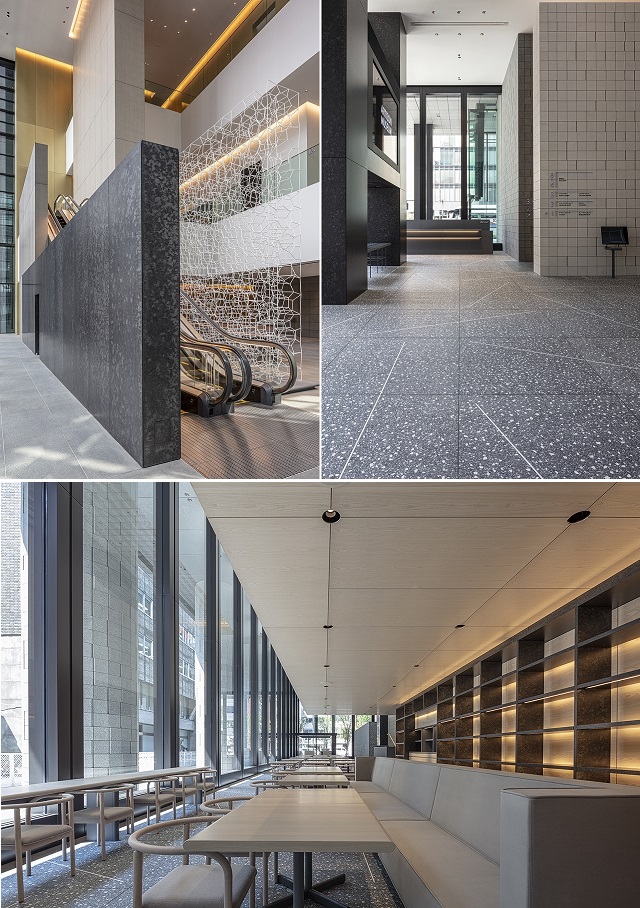

Top Left: 3F Main Lobby, Independent Wall

Top Right: 1F Entrance Lobby, H-shaped Digital Sign Columns

Bottom: 1F Bookshelves of the Museum Cafe

■‘Experiencing Creativity’

‘Museum Tower Kyobashi’ was completed in 2019, at the intersection of Yaesu Street and Chuo street in Kyobashi, Chuo-ward of Tokyo. Kikukawa participated in the metal constructions of the ‘Artizon Musem’ that occupies the 1st to 6th floors within this museum tower.

The concept of the Artizon Museum is ‘experiencing creativity’ inherited from its predecessor, the Bridgestone Museum of Art. To emphasize this concept, the architecture has a welcoming design, and the entire facility is oriented to experiencing creativity through seeing, understanding, and experiencing.

To materialize the welcoming design intent, ‘human warmth’ was one of the defining elements in selecting the materials for this project. ‘Human warmth’ was expressed by selecting finishes that maximize the texture of the material, which applied to Kikukawa metals and finishes selected for this project such as bespoke brass metal sheets, and zinc phosphate coated steel.

A visible example of the concept is the steel monument, or perhaps a sculpture, crafted by Kikukawa in the main lobby named ‘FOAM’ which allows visitors to experience creativity through seeing a solid form of bubbles.

■Combining 3D Data and Craftsmanship

The steel monument, ‘FOAM’ derives its design from bubbles, modeled in 3D as its shape cannot be expressed fully on paper. Using Rhinocerous and Grasshoppers, 3D modeling and design software, the free-form design was expressed, reviewed, and studied from design, detailed design, and fabrication. To fully understand the shape of the monument, 3D printers were used to create partial models.

The final sculpture is 5470mm wide, 5390mm high with 780mm depth, crafted from welded 8mm diameter steel round bars and finished with urethane resin-baked coating. Complex patterns were crafted in 6 units within the factory, then integrated together onsite by welding. Thus, the dimensions or angles of the welded steel round bars required high accuracy in fabrication, which were ensured by Kikukawa’s craftsmanship and bespoke frames or specially developed mounts.

Click here for more information on Kikukawa’s Design Assistance

■Bespoke Brass Metal Sheets

The brass products used within the Artizon Museum and Museum Tower Kyobashi are mostly fabricated by Kikukawa. Due to the designer’s commitment to a gentle, warm gold colour, the selected brass alloy has brighter gold than the typical brass sheets – it is a bespoke material (Cu60Zn40) that is not readily available on the market.

To procure bespoke brass sheets on a large scale of roughly 35.9ton was unprecedented and required various considerations. Based on years of partnership, Kikukawa worked closely with the brass metal sheet fabricators to ensure consistent and high-quality procurement of the material. Additionally, careful inspections were conducted at each fabrication process for quality control.

■Implementing Details with Brass

The elevator halls, exhibition lobby, lecture rooms on the 3rd floor, and information room on the 4th floor are lined with Kikukawa’s bespoke 3.0mm thick brass PHL (vibration) finished cut-edge detailed wall panels. While most panels are 1m by 3m in dimension, the largest extend up to 6.8m in length.

Given the 6mm thin joint details and 40mm allowance requirement, the backing details of the panels were carefully studied and considered. The resulting minimal backing frames created concerns for breakage during shipping but were addressed by designing specialized jigs. These jigs also contributed to a more efficient installation.

The 10.9m wide, 3.2m high opening leading to the lecture rooms are separated by eight doors, each fitting crafted from bespoke brass. To enable the flexible use of space, these doors can be moved to connect the lecture room and its adjacent space.

Other bespoke brass products by Kikukawa include die-casted glass handrail cap pieces within the atrium, and door frame works. Each item was carefully reviewed, fabricating prototypes as needed, to implement every detail requirement of the project.

■Zinc Phosphate Coated Steel

Hot dip galvanized and zinc phosphate coated steel create luxurious texture and colour for any given space. Within the Artizon Museum, a dark shade of zinc phosphate coated steel is used as an accent in various places. The basic detail of these 3.2mm thick steel panels follow that of the bespoke brass panels to implement the 6mm thin joints with 40mm allowance requirements. Almost all of the zinc phosphate coated panels, including those used for the interior decorations and fixtures, are made by Kikukawa.

Dark zinc phosphate coated steel wall panels can be found in the 3F main lobby, 65㎡ of the wall panel next to the escalator, and the independent wall panel behind the escalator. A unique space exists within the main lobby from the contrast between the dark shades of the steel panels and the white ‘FOAM’ by the escalator.

The steel wall panels consist of those with a typical dimension of 900mm wide and 3000mm high, and those crafted from various triangles or trapezoids to align with the required shape. Other dark zinc phosphate coated panels include the 11.7m wide, 2.7m high bookshelf found in the museum cafe on the first floor. These book-shelf panels, consisting of 10 rows of 420mm deep partition and five shelves with 3mm thin joint, are crafted with carefully considered backing details for a clean flush surface.

Unlike other steel products, the steel handrail by the wall in the first-floor entrance lobby is coated with dark powder paint coating. A built-in lighting box is installed inside these steel handrails that were metalworked into a semi-circle.

Click here to find out more about Kikukawa’s Zinc Phosphate Coating

■Providing Comprehensive Solutions for Metal Constructions

By collaborating with interior general contractors, and other subcontractors or affiliates, Kikukawa responded flexibly to changes in plans during the installation phase that is common with big-scale and complex projects.

Artizon Museum is an example of a project that fully showcases Kikukawa’s comprehensive ability in metal construction; from designing details in 3D, procuring bespoke materials, quality control, flexible responses to various requests and changes during installation. Upon the opening of the museum, a small gallery of materials used within the museum was displayed on the 6th floor, including Kikukawa’s bespoke brass metal sheet and zinc phosphate coated steel with our company name.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| 3F Main Lobby Metal Artwork, FOAM |

Steel | Urethane Resin Paint 3D-CAD |

| ELV Hall, Exhibition Lobby and Others Wall Panels, Fittings |

Bespoke Brass | PHL Bespoke Fittings |

| 3F Main Lobby and Others Wall Panels, Artworks |

Steel | Zinc Phosphate Coating |

| Project | Artizon Museum |

|---|---|

| Abbreviated Name | Artizon Museum, Ishibashi Foundation |

| Client | Ishibashi Foundation |

| Architect | Design, Supervision: Nikken Sekkei Ltd. Museum Interior Design: TONERICO: INC. |

| Contractor | Toda Corporation Museum Interior Contractor: Sogo Design Co., Ltd. |

| Completion | 2019 |

| Location | (Within Museum Tower Kyobashi) Chuo-ward, Tokyo |