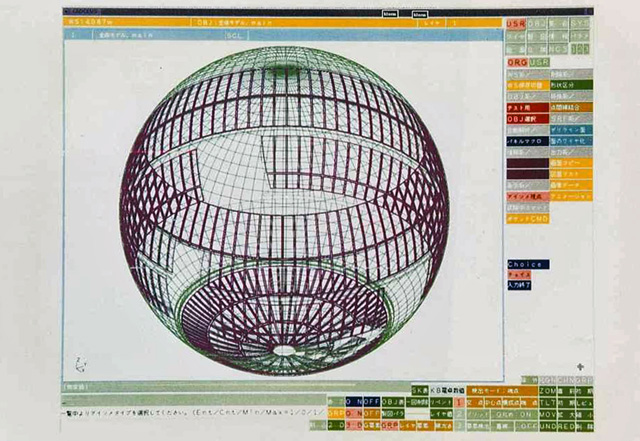

Design data of the spherical observation room of Fuji TV building

As experts in metal architecture, Kikukawa’s design team provides consultation and assistance to ensure the success of various projects. Based on years of experience in bespoke architectural metalwork, Kikukawa’s design services consist of the following: expertise in design details, extensive understanding of fabrication front-line that translates to manufacturable drawings, collaborations with stakeholders for smoother installation and a wide range of accommodations in design communication.

As exemplified by Kikukawa’s corporate philosophy, Kikukawa is continuously taking on new projects and challenges, as bespoke metal-artisan. This includes accommodations of BIM softwares and/or 3D data designs, and our continuous efforts to improve our services and technology.

| Main Features | -Detail design of architectural projects with over-sized, extra long or bespoke metal products -Renovation projects requiring field measurements -Monuments requiring strength calculations -Collaborations using 3D data or BIM softwares -3D detail design |

|---|---|

| Applicable Materials | Metal architectural products -Aluminium -Stainless steel -Steel -Bronze alloys -Others |

| Categories | 3D-CAD softwares -Rhinoceros -Inventor -Vectorworks -SolidWorks BIM software -Autodesk Revit |

| Maximum Workable Size | Varies depending on the material, shape and/or fabrication methodology. Please consult us for more information. |

From designing details to shop, assembly and installation drawings - even crating plans utilize the 3D design data

■Requirements of Detailed Design Within Metal Constructions

Metal is considered to be the most workable material amongst the building materials.

Within the architecture industry, each step of the implementation process; from design, fabrication, assembly, and installation, require a deep understanding of the applicable material. This is especially true for Kikukawa designers, whose skill requirements include the understanding of various details and metal-crafting technologies, for its extensive line of business. Additionally, detail designers are required to consider the joints and mounting of other building elements, which necessitates highly specialized expertise and thorough communication.

■Implementation and Benefits of 3D design (and BIM)

Fluid designs with complex geometries are increasing with the introduction and wide-spread usage of 3D-CADs, 3D models and BIM software. As the “most workable building material”, the role of 3D design in metal constructions is becoming more meaningful.

Designing in 3D means reliance on 3D models to visualize details. This enables a deeper understanding of the design for internal and external communications, which leads to smoother collaboration works such as interference checks. In comparison to processes based on 2D drawings, conversions of 3D models to 2D drawings enjoy shorter lead-time and reduction of errors, such as overlooked drawing corrections.

■Designing Details with Kikukawa

Kikukawa’s teams of designers provide consultations and design assistance throughout the project to ensure constructability and success. As a comprehensive solution provider, Kikukawa responds to requirements and needs of complex projects and challenges, by designing feasible details and value engineering. Collaborations and communications at the design phase with consideration to later processes improve the overall efficiency of the project. From new buildings to renovations and monuments, Kikukawa continues to challenge itself to realise innovative designs.

- 1. Providing Design Solutions

Bespoke constructions and fabrications require careful detail considerations to the requirements of each project. Consideration requirements include cost, quality, timeline, and fabrication feasibility, installation details as well as the overall constructability of the project through collaboration with other stakeholders.

Kikukawa shares its know-how and experience within its organization, which builds a solid foundation of knowledge with a basis in the manufacturing frontline.

Regardless of the complexity of the product shape or project, Kikukawa provides consultation and design assistance, including anti-seismic strength and wind resistance calculations, deflection calculations, and considerations to inter-layer displacement and allowance.

- 2. Feasible Designs

Through collaborations and planning, Kikukawa delivers the best solutions in implementing designs.

During the manufacturing process, metal sheets experience minuscule spring-backs, deformations, and elongations. Accumulation of this can become a source of decline in product quality and precision. Each difficulty experienced in the manufacturing front-line is communicated to the design team to deepen the understanding of the metal and its processing requirements or restrictions. New projects or shapes are tested through sample fabrication and mock-ups. These efforts have built realistic knowhow which is incorporated in our designs.

To ensure precision and quality, Kikukawa applies the 3D design data to the various NC machinery. In addition to this, Kikukawa’s highly skilled craftsmen inspect and make adjustments by millimeters for further quality control.

- 3. Accommodations of Design Softwares (3D CAD and BIM)

Since the adoption of 3D-CAD in the early 1990s, Kikukawa has been leading the industry with its accommodations in 3D design assistance and its applications.

As a bespoke metalworker, Kikukawa is often tasked to implement products or projects with pioneering design or systems. By responding to these requirements, Kikukawa has been adopting and refining its accommodations in various CAD, CAM, and 3D software.

■Projets with 3D Design Software

◆Avex Building (Reception Counter)

A three dimensional “a” shaped counter that is 3.6m high, 4.8m wide, 4.3m in depth. From the panels to the frames, a 3D model was drawn and used for field adjustments onsite to realise a 3mm joint.

Click here for more information on the project: Avex Building (Reception Counter)

◆Bloomberg London Headquarters

A site that is roughly 13,000m2 (3.2acres), houses a new headquarters with bronze constructions that was fabricated by Kikukawa. Based on the 3D data from our clients, all of our communication on the design was done in 3D data.

Click here for more information on the project: Bloomberg London Headquarters

◆Sumitomo Fudosan Azabu Juban Building

An iconic building built with various triangles installed at various angles. The 3D design data was used to communicate with the client and on-site during installation.

Click here for more information on the project: Sumitomo Fudosan Azabu Juban Building

◆Sumida Hokusai Museum

A curious and complex design that relied on 3D-CAD to design the details.

Click here for more information on the project: Sumida Hokusai Museum

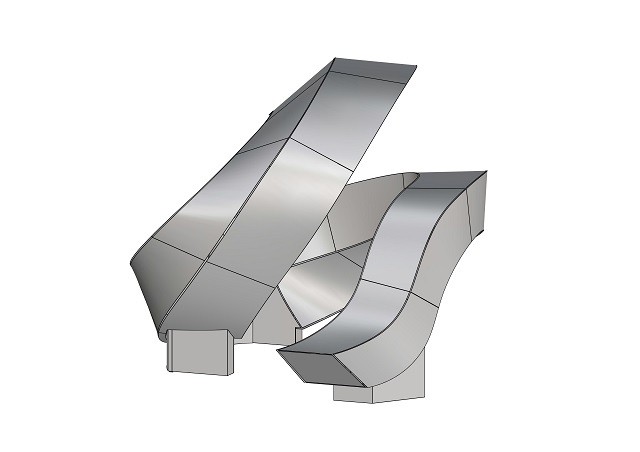

◆Tokyo Station, Yaesu Central Ventilation Tower

An independent shell shaped structural monument, designed in 3D CAD.

Click here for more information on the project: Tokyo Station, Yaesu Central Ventilation Tower

◆Chukyo University, Nagoya Campus

A monument inspired by a pterosaur’s foot and its egg.

Click here for more information on the project: Chukyo University, Nagoya Campus

◆Arts Maebashi

A 10mm thick perforated aluminium facade waves and curves to enfold this building.

Click here for more information on the project: Arts Maebashi

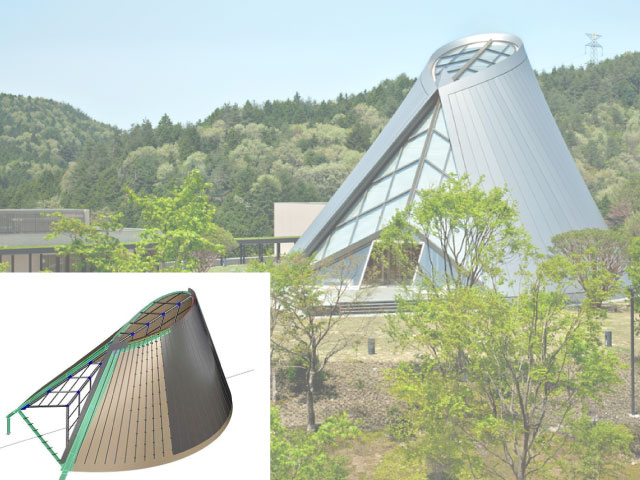

◆MIHO Art School

Using 18.5m long stainless steel and panels that are between 600mm to 1,500mm wide to make a facade that gently welcomes guests to this chapel.

Click here for more information on the project: MIHO Art School

◆Fuji Television Network, Inc., Spherical Observation Room

A landmark of Odaiba, the massive globe is covered in titanium panels.

◆For other projects that used 3D-CADs

■Other 3D Projects

◆A Case of 3D Design, A Giant Arch

Metal Craft News introducing an arch that was made from a 3D model.

Click here for more information on the project: A Case of 3D Design

■Please Consult Us

By combining cutting-edge technology and expert craftsmanship, Kikukawa has been providing bespoke metal-craft over the years. With this expertise, Kikukawa’s design team offers consultations and design assistance for various projects.

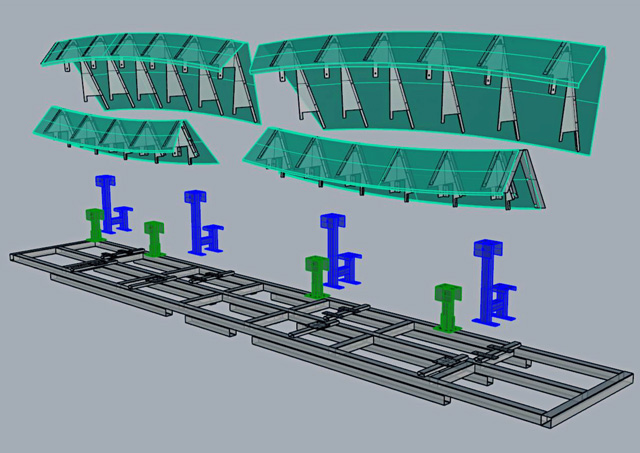

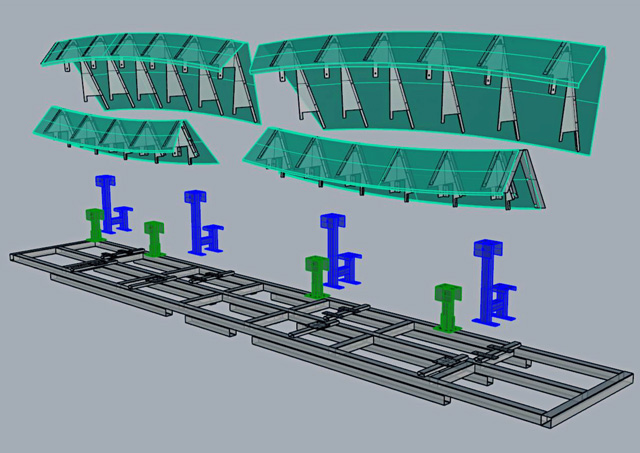

From designing details to shop, assembly and installation drawings - even crating plans utilize the 3D design data

The 3D design of a chapel and the actual Chapel of MIHO Art School

A 3D design data of a complex, and 3D shaped reception counter

A Kikukawa designer drawing. From those who prefer to draw in 3D to those that prefer by hand, designers with diverse expertise come together as required