We fabricated a serving counter for the staff cafeteria. The three-dimensional shape was extremely challenging to achieve, particularly the acute angle (33 degrees) at the corner parts.

Seamless joints were achieved both for the stainless steel countertops and the aluminium side panels. All efforts were made to ensure joints and screws were invisible.

Seamless joints were achieved both for the stainless steel countertops and the aluminium side panels. All efforts were made to ensure joints and screws were invisible.

Ceiling panels in mirror-polished stainless steel, designed to evoke ripples on the surface of water.

Ceiling panels in mirror-polished stainless steel, designed to evoke ripples on the surface of water.

■A singular, enchanting space featuring three-dimensional counters and Minamo® panels

KIKUKAWA was recently commissioned to work on the interior of the Isuzu Motors staff cafeteria, which is located in Yokohama Gate Tower, a large-scale multi-purpose building in Yokohama City.

KIKUKAWA fabricated and installed counters making up five distinct areas and a ceiling featuring our bespoke Minamo® panels. The presence of these metal products, at once design-led and functional, contributes a singular sense of elegance to the space.

■Three-dimensional counter side panels fabricated in cast aluminium

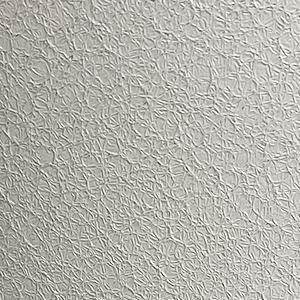

Crystalline powder paint

The counters featured in the cafeteria are 900mm-1100mm in height and are made from 1.5mm-thick stainless steel countertops finished in PHL (vibration), and 2.5mm-thick aluminium side panels, R-bended vertically to meet the countertops. These side panels have been coated in a white crystalline powder paint, which produces a distinctive textured effect resembling wrinkles across the surface. This coating was developed specially for the project: we took inspiration from the coatings used on engine covers in cars, and created and adjusted multiple samples until we achieved perfection. The side panels for the fifteen corner sections of the counters are three-dimensional shape. For this reason, we fabricated them in cast aluminium. The process of creating the corner sections involved client meeting using drawings and models by 3D CAD, and sharing the process with the client through mock-up reviews.

Click here to find out more about Kikukawa’s dual curving technology

Click here to find out more about Kikukawa’s designing details

■Designed to achieved coherence between style and functionality

The counter side panels comprise aluminium panels of 1200mm-2500mm in length. The fitting of the joints of those panels is testament to KIKUKAWA’s technical prowess and extensive know-how. To meet the client’s request of invisible joints, we used butt joints. The joints between the side panels and the cast corners presented a particular challenge, due to the differing thicknesses and the precision of the R-bends, but we were able to achieve gap-free joints by making careful adjustments. We achieved an invisible fit with minimal screws by also using the hooking system, resulting in a beautifully smooth silhouette that further highlights its three-dimensional shape.

Since our commission was to create kitchen counters, it was necessary to ensure we met our client’s requirements not just in terms of design, but also in terms of functionality. For example, the countertops feature tray rails with detailed chevron-like bending. In addition, we gave careful consideration to the placement of the backing frames and any metal accessories, to ensure they did not interfere with the integrated storage cupboards and plumbing equipment. In this way, we worked to ensure that our design specifications were adapted to the intended uses of each counter area.

■Minamo® panels depicting the origins of the client’s company name

The 4m x 25m suspended ceiling in the dining table area is constructed from Minamo® panels made with 2mm-thick mirror-polished, embossed stainless steel. These panels were made to a bespoke specification, to evoke the Isuzu River that flows through the Ise Grand Shrine and was the inspiration for the client’s company name. Specifically, the embossing on these panels is more random and defined than our standard patterns. The ceiling comprises twenty-eight cut panels of 900mm(W) x 3950mm (H) each, with joint widths of 3mm. By using a hook-type fitting, which enables screws to be made invisible, we were able to make it seem like the Minamo® panels were floating below the exposed ceiling.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| Counter Wall Panel | Aluminium | Crystal-like Powder Paint Coating Dual Curving Technology |

| Counter Top Panel | Stainless Steel | PHL |

| Water Ripple Ceiling Panel | Stainless Steel | Mirror Finish + Embossing |

| Project | Cafeteria at Isuzu Motors |

|---|---|

| Client | Isuzu Motors Limited |

| Architect | Isuzu Estate Co., Ltd. Sakakura Associates architects and engineers |

| Contractor | Kajima-Tekken-Omata Construction Joint Venture |

| Completion | 2022 |

| Location | Yokohama-city, Kanagawa |