We developed a new fabrication method to bend unique shapes to be able to achieve these challenging semi-conical arched panels

The ground floor outside walkway: the combination of the structured geometric-patterned ceiling and the lighting creates a stunning effect

The ground floor outside walkway: the combination of the structured geometric-patterned ceiling and the lighting creates a stunning effect

■Design-led Metal Ceiling for Acclaimed Entertainment Complex

Kabukicho, in Shinjuku Ward, is the heart of popular entertainment and culture in Tokyo. It is also now home to the Tokyu Kabukicho Tower, standing some 225m tall with a distinctive, fountain-inspired façade design. The concept for the building was “the ultimate in entertainment” and it is now Japan’s largest* high-rise mixed-use building, housing a hotel and multiple entertainment facilities including a cinema, a theatre, and a concert hall.

KIKUKAWA was involved in the project through the fabrication of a three-dimensionally structured ceiling consisting of overlapping semi-conical panels. This stunning design-led ceiling, achieved through metal fabrication, brings a sense of dynamism to this unique entertainment space.

*Survey on Multi-Use Building Facilities (200m or more in height and housing both a hotel and entertainment facilities, e.g. cinema, theatre, concert hall) in Major Tourist Destinations in Japan

Survey period: March 2022

(Survey conducted by Trending Future Research Institute)

■Crafting Semi-conical Aluminium Panels with a Special Bending Process

The ceiling of the ground floor outside walkway and bus terminal at the front of the hotel entrance is crafted from 250 triangular arched panels resembling a cone cut in half lengthwise. The design was inspired by ripples on the water surface and the resulting structured geometric pattern makes a strong impression on visitors.

Each semi-conical arched panel is a bent panel fabricated from 2mm thick aluminium. The standard panel size is 1,390mm (width) by 1,670mm (length), with a gap of 300m between the highest point on the curve of the arch to the ceiling. The panels are secured with screws on 23mm wide joints and finished with a silver powdered coating.

The biggest challenge this project presented was how to bend the panels into the required semi-conical shape; this was something we had not attempted before. In particular, the tip of the cone shape becomes very narrow, and this thinnest point would break when we tried to use the standard press bending method. In response, we used the know-how we have accumulated at KIKUKAWA to date to develop a new processing method specifically for achieving this unusual bending shape. This method enabled us to fabricate a large number of these special panels while maintaining consistent quality.

■Using 3D Models to Address Complex Interfaces

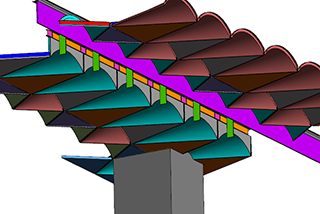

▲Part of the 3D model

In this ceiling, triangular ceiling panels are arranged alongside large and small arched panels and flat panels with no arch. In addition, the ceiling was designed to connect with other surrounding elements, such as a board ceiling, a glass curtain wall, and column-style panels. To achieve this, we examined the optimal fit with each element and created design drawings. The aim of these was to be able to explain shape and fit clearly to the architects, using 3D models that could be moved in and seen from all directions.

Designing the substrate for the ceiling was challenging as the ceiling itself contained so many facilities, so we worked with other suppliers from early on in order to create workable drawings. We had to change a number of points in our original plans for mounting, but we made sure to coordinate closely with main contractors and shortened the overall installation time by pre-assembling some of the substrate at our factory before bringing it on-site. Our overall approach was to be flexible and agile in our responses.

Click here to find out more about KIKUKAWA’s Designing Details

■Tackling Challenging Metal Fabrication with Creative Thinking

The ceiling panels for this project were in a shape that was extremely challenging to fabricate. Despite this, KIKUKAWA was able to accomplish this with our outstanding capabilities in both three-dimensional projects and fabrication technology. Designs that seem impossible at first glance can be achieved when we combine our in-house experience and expertise to find a solution. If we cannot find a solution using existing methods, we look at the problem from new angles and develop new fabrication methods. This is why this particular project was possible to achieve: thanks to our team for their creative thinking and refusal to give up.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| 1F Passage Celing Panel |

Aluminium | Powder Paint Coating Bespoke Bending |

| Project | TOKYU KABUKICHO TOWER |

|---|---|

| Client | TOKYU CORPORATION TOKYU RECREATION CO.,LTD. |

| Architect | Kume Sekkei - Tokyu Architects & Engineers JV Exterior Design: YUKO NAGAYAMA & ASSOCIATES |

| Contractor | SHIMIZU CORPORATION - TOKYU CONSTRUCTION JV |

| Completion | 2023 |

| Location | Shinjuku-ward, Tokyo |