Building 8 covered in unitized steel Shippo patterned panels

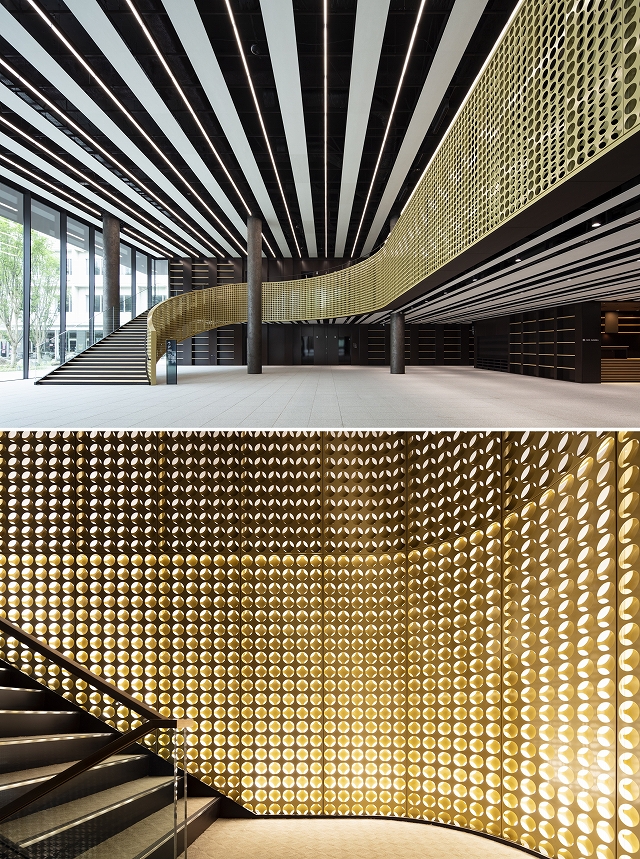

Above: Spiral staircase at the entrance hall. The dual curved panels are installed beautifully.

Above: Spiral staircase at the entrance hall. The dual curved panels are installed beautifully.

Bottom: Staircase at the library area. Even the corners are installed with 3mm thin joints.

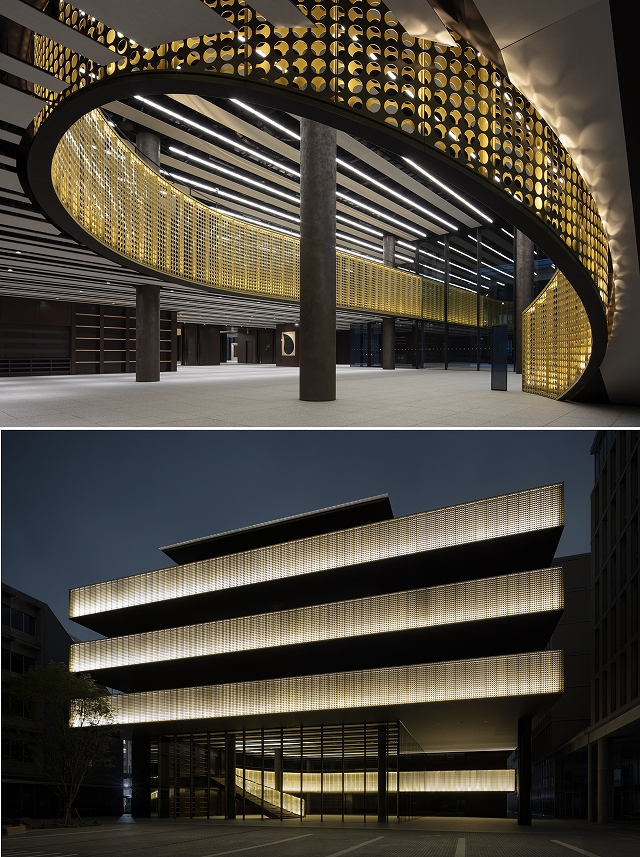

Above: The majestic night view of the spiral staircase.

Above: The majestic night view of the spiral staircase.

Bottom: The Shippo patterned panels illuminate the campus at night

■Crafting the Design Motif, Shippo Pattern, with Metal

Taisho University is a Mahayana Buddhist university, founded roughly 100 years ago at West Sugamo. Along with the renovation of the symbolic chapel, Building 8 was newly established as a comprehensive learning support facility that also holds a chapel hall, library, and large-scale common room.

Kikukawa participated in the metal construction of this project, the Shippo patterned unitized panels installed in and outside of this new building. Shippo pattern is the design motif of the building, implemented by overlapping two shifted layers of perforated panels.

*Shippo Pattern: Shippo, meaning seven treasures, refers to gold, silver, lapis lazuli, crystal, agate, red coral, and carnelian in Buddist Scriptures. The design pattern is created by overlapping circles shifted by quarters horizontally and vertically. This motif is considered auspicious, embodying wishes for family happiness and financial success.

Click here to learn more about Kikukawa’s Perforating Technology

■Creating an Actual Size Mock-up

Kikukawa’s participation began with the technical consultation of the Shippo patterned panels. Since our participation, it took over two and a half years to complete the project which required various trials and errors to ensure and establish the necessary quality and technology. Decisions on specifications were made through samples and mock-ups, including those fabricated to actual size. Since the design is achieved by overlapping two panels, precision was a key element in ensuring quality. Especially for curved areas, difficulties or challenges were identified and addressed prior to the mass production.

One of the defining features of the Shippo patterned panels is the lighting, thus the finish of the panels was key. Kikukawa crafted 7 differently coloured powder paint-coated samples and considered each reflectance to decide the final colour. Similarly, to ensure that the product is in line with the design intent, a mock-up was crafted and inspected with the client to carefully make the final decision on the colour and shapes. Finally, the installation was adjusted by 0.5mm units to ensure the best lighting condition.

■Interior / Exterior Steel Shippo Patterned Panels

The new Building 8 is covered in roughly 1600㎡ exterior Shippo Patterned panels. The design is implemented by overlapping two layers of slightly shifted 1.6mm high corrosion resistant perforated steel panels and a backing panel. The standard dimension of the unitized panel is roughly 600mm wide, 2400mm high, finished in gold polyester powder coating. The perforation is roughly 100mm in diameter at 120mm pitch, and the panels are shifted 1/4 vertically and horizontally to create the Shippo pattern. The 3mm thin joint was implemented by optimizing the backing panel system based on the calculated strength of the unitized panel.

For the interior panels, a similar backing system was adopted. The Shippo patterned panels are installed within the library on the fourth floor (110㎡)and the atrium curtain board on the second-floor learning commons room (191㎡).

■Dual Curving the Shippo Patterned Panels

The interior staircase, the staircase wall panels connecting the first to the fourth floor, and the spiral staircase panels stretching from the entrance hall are all lined with Kikukawa’s Shippo patterned steel panels. These curved or dual-curved panels were especially challenging, given the 3mm thin joint requirement and high-quality standards of the project. With expertise and using various measures, Kikukawa addressed and resolved each challenge.

For instance, curved panels require welding. However, since the selected material of the panel is thin and the selected finish was high in gloss level, the welding quality would directly affect the final quality of the product. In order to address this, Kikukawa’s craftsmen carefully calculated the placement, degree of the welding, and the metalworking process to achieve the quality required.

Prior to the installment of the spiral staircase, the steel stringer was measured in detail on-site to accurately craft and place the brackets during manufacture. During the installment process, the 3D data of the panels were released to the craftsmen so that the R angle of the radiation could be adjusted carefully to create a smooth spiral.

Click here to learn more about Kikukawa’s Dual Curving Technology

■Balancing Functionality and Aesthetics

Thirty-six meters of Shippo patterned spiral staircase panels consist of a built-in handrail stanchion and two perforated panels. Crafted from 60 sets of differently shaped unitized panels, the typical size of the unitized panels is 600mm in width, 2400mm in height. The bottom half has a built-in lighting system to create a majestic night-view.

Roughly 200㎡ Shippo patterned panels line the corner of the staircase landing, consisting of standard size 720mm wide and 2400mm high unitized panels. Unlike the spiral staircase panels, the lighting system is equipped behind the unitized panels. Plus, there are sound-proof backing systems and there are horizontal 3mm thin joints between the panels. These staircase landing panels require routine inspection, however since the Shippo patterned panels consist of two overlapping unitized panels, simply providing an opening was not sufficient for inspection. To balance both functionality and aesthetics, barely noticeable access panel details were designed; the perforated panel at the back can be removed whenever necessary.

■Innovations for Tomorrow

For this project, Kikukawa was highly regarded by the client for our high-quality services from design to installation, and our craftsmanship. In particular, the 3mm thin joints and the dual-curved Shippo panels received a glowing review.

In design implementation, quality, and quantity, this project required high standards and innovations to hone our craftsmanship.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| Exterior Panel Shippo Pattern Panel |

Steel (High Corrosion Resistant Coated Steel) | Polyester Powder Paint Coating (Metallic) Unitized Design Perforation |

| Entrance Hall Spiral Staircase Shippo Pattern Balustrade Panel |

Steel (High Corrosion Resistant Coated Steel) | Polyester Powder Paint Coating (Metallic) Unitized Design Perforation Dual Curving |

| Library Staircase Shippo Pattern Wall Panel |

Steel (High Corrosion Resistant Coated Steel) | Polyester Powder Paint Coating (Metallic) Unitized Design Perforation |

| Project | Taisho University Building #8 |

|---|---|

| Client | Taisho University |

| Architect | Obayashi Corporation |

| Contractor | Obayashi Corporation |

| Completion | 2020 |

| Location | Toshima-ward, Tokyo |