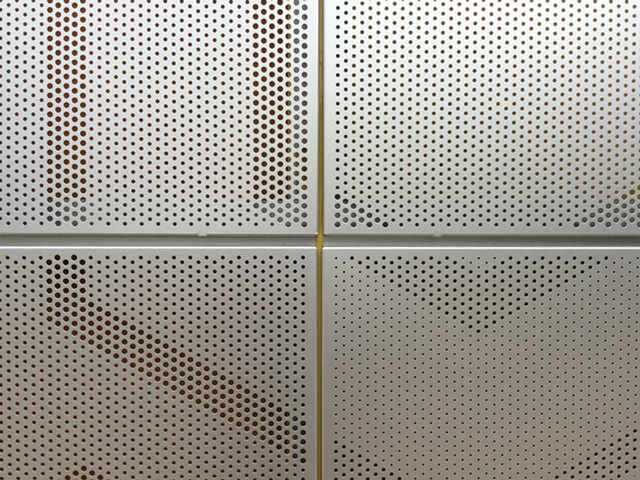

A designed perforation pattern, fabricated at Kikukawa

By combining Kikukawa’s machineries, tools, and metal-craftsmanship, we provide a wide range of high-quality perforations to various metal sheets and metal products. Applicable materials include copper alloy, aluminum alloy, steel and stainless steel, and workable thickness ranges from 0.8 mm to 10 mm. Perforations of extra long or over-sized metal sheets, as well as 3-dimensional products, are also available.

Perforated metal products are functional for balancing light and ventilation while adding a decorative touch to each project. Kikukawa is able to provide many perforation options, in shapes, sizes, geometric patterns, and finishes. By combining this with other metal-crafting technology, Kikukawa is able to provide a comprehensive metal-working solution.

| Main Features | - Extra long and over-sized perforations available - Able to accommodate thin to thick metal sheets - Accommodates 3D data - Able to accommodate small lots of a high-variety product lines - Complex and 3D shapes possible |

|---|---|

| Applicable Materials | - Aluminum alloy - Stainless steel - Steel - Copper alloy |

| Categories | - Perforation - Thick sheet perforation - Bespoke perforation - Variably perforated (gradient) perforation - Embossing (Kikukawa’s “Rough-tone” metal) - Moire effect |

| Maximum Workable Size | Perforation methodology and limitations differ depending on the material and shape. Please consult us for more information. |

The circular shape is perfected by perforating after shaping the metal

■ Benefits of Perforated Metal

1) Functionality

Generally, perforated metal products are used for areas that require durability and a certain level of open-ratio. Perforations provide a filtering effect to control light and ventilation, and act as a screen. The design versatility and the workability of metal leads to uses such as monuments, chairs, tables and interior decorations, as well as facades, partitions, and louvers, ceiling materials or railings in architecture.

2) Aesthetics

Metal perforations provide a sleek, sharp ambiance and are highly versatile in design. With thinner sheet metals, it provides a sense of openness while thicker sheet metals exude a stately, luxurious façade. By controlling the perforation open-ratio, concepts such as see-through façade that exposes the bones of the building, or a functional curtain-wall that provides a certain level of privacy and ventilation are implemented.

3) Versatility in design

By controlling the geometric patterns, shapes, sizes, or even the thickness of the metal sheet, a wide range of designs can be realised.

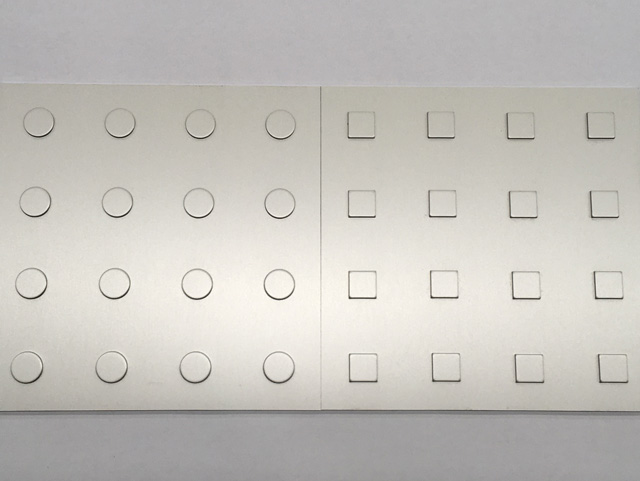

The ambiance of classic patterns such as round, slotted, square or rectangular ones can change greatly depending on their orientation and size. Examples of such applications include moiré or bespoke designs.

■Why Kikukawa?

1) Diversity of machinery and tools

Kikukawa holds multiple machineries such as NC turret punch presses or fiber laser cutting machine, and over 50 perforating dies. Because of this, Kikukawa is able to choose the most suitable and efficient fabrication methodology to meet the requirements.The fiber laser cutting machine is able to cut out complex or unique patterns that would have required a new die.

Furthermore, Kikukawa holds a wide variety of dies with different shapes and sizes; from classics such as round, square, slotted and rectangular shapes, to embossing dies or deep drawing dies.

Kikukawa also invests in new tools or machineries as required, further increasing the possibility of designs that we could realise.

2) Designing technology

As a bespoke metal-crafting expert, Kikukawa has a group of experienced designers that can draw the details to realise concepts. An example of this is Arts Maebashi – the frames are designed so that the structure of the building is difficult to see through the perforated exterior.

Kikukawa is able to fabricate high-quality perforations, and design details that are suitable for the concept of purpose.

3) Providing a comprehensive solution

At Kikukawa, we control our products from design to its finishing stages. Therefore, we have the machineries and tools, and the know-how to choose the most suitable fabrication methodology to ensure the quality required. Our perforation is precise, in shape and dimensions, and the metal-sheets are considered for burrs and flatness, as part of our comprehensive quality control.

■Applications of Kikukawa’s Perforation

Here are a few examples of Kikukawa’s projects with perforation.

◇Perforating thick aluminium

With a typical turret punch, it is impossible to perforate 10mm thick aluminium. However, in order to implement the design intent of thick aluminium with varying sizes of round perforation, Kikukawa relied on a specialized tool.

Click here for more information on the Sugamo Shinkin bank, Tokiwadai branch

◇Perforating three-dimensional sheets over the market available size

Two bronze metal sheets were welded, shaped to a bowl then perforated to realise this bespoke gate. A combination of the latest welding and shaping technology was used to create its shape and a specialized tool was used to perforate the product.

Click here for more information on the bespoke gate of Shiki Juraku

◇Perforating thick three-dimensional metal sheets

A white curved façade with gradient perforation – in order to materialise this design concept, with minimal backing frames and the necessary strength, Kikukawa relied on 10mm aluminium metal sheets. Using a specialized tool, high-quality perforations ranging from 80mm to 140mm were opened.

Click here for more information on Arts Maebashi

◇ Designed perforation (Moire effect)

Here is a monument with two slightly offset gold painted perforated panels superimposed onto each other.

Click here for more information on Chukyo University, Nagoya Campus

◇ Precise perforation

Bloomberg London is lined with perforated louvers that enhance the ventilation of the building. To satisfy the high open ratio requirements, perforations were required to the bent edges. Given the smooth curving geometry of the louvers, the fabrication required that the metal sheets were perforated, corrugated then stretched to the required curvature. To satisfy this and the high tolerance, Kikukawa applied the design data to the NC turret punch press machine.

Click here for more information on Bloomberg London’s Arcade

◇ Embossing (Kikukawa’s “Rough-tone”)

Embossing or deep-drawn metal sheets are also available.

Click here for Kikukawa’s “Rough-tone” catalogue (Japanese)

◇ Bespoke perforation

Projects with bespoke or small lot ornamental perforation pattern requirements can be satisfied with Kikukawa’s laser cutting technology.

◇ Classic patterns

In addition to the bespoke, unique or complex perforations listed above, Kikukawa holds the tools to perforate classic patterns, including round, square, slotted and rectangular shapes in varying sizes and layouts.

■ Please consult us

From thin to thick metal sheets, to complex shapes or products, Kikukawa provides high-quality perforations to various metals. In addition to having the experience and tools to provide a wide range of perforation patterns, Kikukawa invests in tools or machineries to satisfy requirements. From consultations on bespoke patterns to fabrication feasibility, please do not hesitate to contact us for solutions.

The circular shape is perfected by perforating after shaping the metal

Top: R curved perforated louver. Bottom: A moiré effect by superimposing two perforated metal sheets.

Kikukawa has embossing dies

Designed ceiling panel perforated with a laser cutting machine