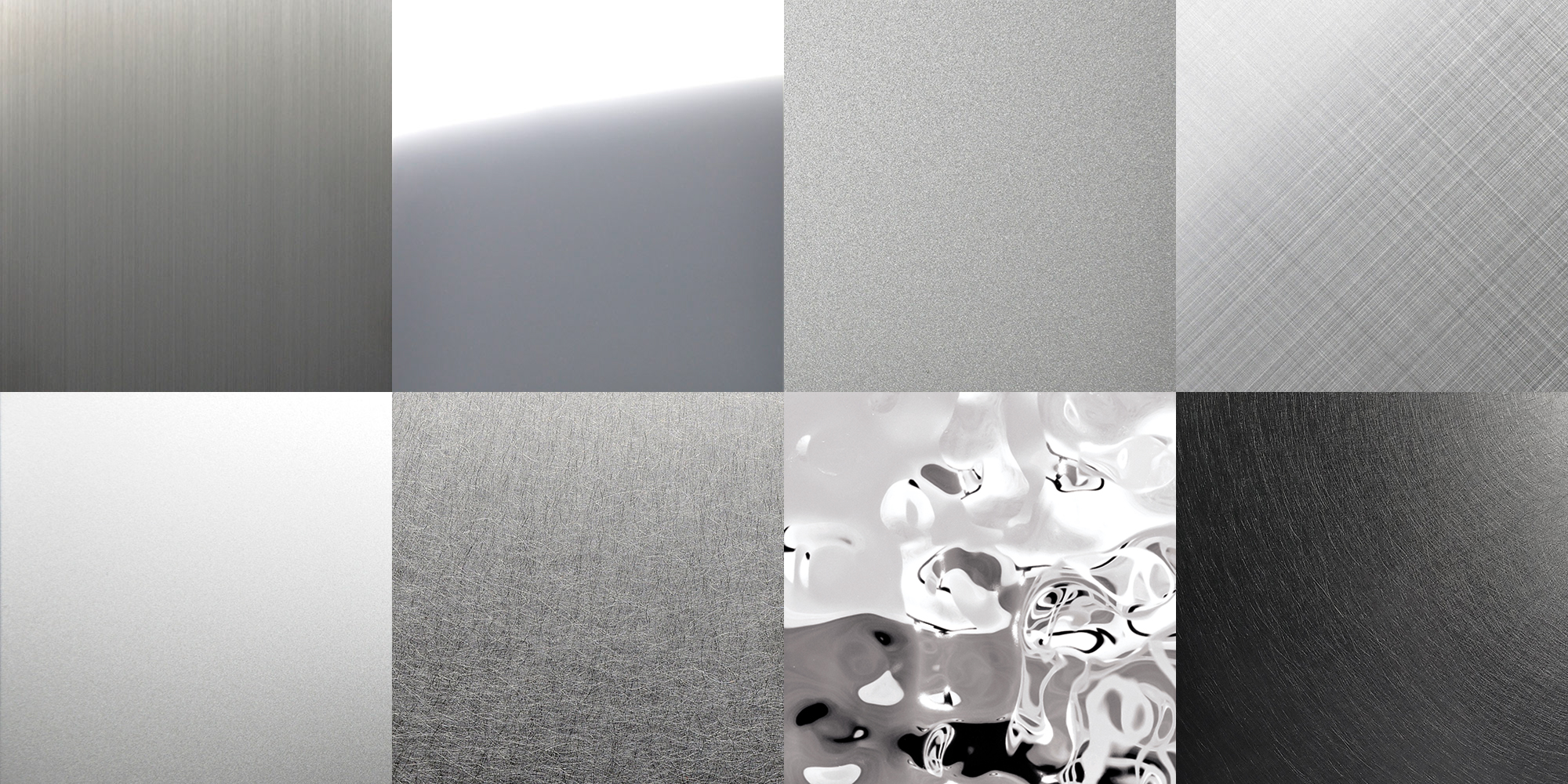

Silky Blast is a finish that utilizes KIKUKAWA’s shot-blasting technology. This is a finish that maintains the metallic physique of stainless steel while adding a silk-like matte texture.

This finish is suitable for both interior and exterior products, as well as panels, ornaments and perimeters.

The larger the sample reference number is, the coarser the finish. The gloss and the abrasion level could be adjusted as required for the project.

KIKUKAWA is able to recreate the passivation coating that was interrupted by any metalworking or the finishing process. Please consult us for further information.

*Please note that for B-series, the maximum available material thickness is 2mm, and the maximum available material width is 1219mm.

Stainless steel has been used in architecture since the early 1900s and its range of applications continues to grow.

A steel alloy, its key characteristic is the minimum 10.5% chromium (Cr) content present in the material. The chromium makes it more resistant to corrosion as it forms a coat of passivation (or oxide film) on the surface. The coat prevents corrosion or prevalent corrosion from spreading which helps maintain the original aesthetics of the material.

The high durability, workability and weatherability of this particular brand of steel makes this metal one of the most functional materials available. Its usage varies from sub-frames for exterior products to facades that rely on the beauty of the material.

In Japan, the most commonly sought type of stainless steel is the austenitic SUS304. The 18% chromium with 8% nickel content composes a metal with higher durability. It is also preferred for its workability in welding or metalworking.

In harsher environments, such as coastal areas, SUS316, ferritic stainless steel or duplex stainless steel may be chosen for its higher corrosion resistance.

*Please note that the photos of the samples are guidelines. Please confirm the finish with an actual sample prior to making your final selection.

Click here to check the contents of KIKUKAWA's Stainless Steel Finish Sample Book