Eaves panel fabricated from highly corrosion-resistant ferritic stainless steel. KIKUKAWA’s know-how enabled the use of a PHL finish even on such a hard base material. (Tokyo Midtown Hibiya)

Permanent Hairline / Vibration (PHL) finish is characterised by delicate, randomly placed grind marks. PHL is widely used as a finish for metal surfaces. Its muted shine softens the impression of metal as cold and inorganic, while also creating an ambiance of luxury and elegance. PHL can be used on a wide range of materials, from interior and exterior panels to fittings and interior features.

| Main Features | -Can be combined with diverse materials and finishes -Grind size and shine can be adjusted -Appearance changes according to how the light hits the surface |

|---|---|

| Applicable Materials | -Stainless steel -Aluminium -Bronze (Native copper / bronze / brass) *We can also apply PHL finishes on other metals. Please get in touch to discuss your requirements. |

| Categories | -PHL (vibration) -Defined PHL -Pearl vibration *Can be combined with other finishes, e.g. Coloured Stainless Steel, Colour Clear Coating, Anodization, Sulfurization. |

| Maximum Workable Size | Max. 1500mm (W) x 6000mm (L) * Please consult with us regarding anything over this size. |

| Remarks | Please note that we do not accept assignments for polishing finishes only. |

Aluminium ceiling panel finished in PHL + secondary electrolytic colouring (silver). This finish imparts an elegant air that invites light into the underground station building. (Ginza Station)

■ What is PHL (Vibration) Finish?

Permanent Hairline / Vibration (PHL) is a surface finish characterised by delicate, non-directional grind marks. Unlike the Hairline (HL) finish, in which all grind marks are straight and uni-directional, PHL is made distinct by its irregular, arch-like grind marks. This is why PHL is sometimes also referred to as “random hairline” or “non-directional hairline” finish. This versatile grinding technique is most commonly used with stainless steel, second only to the HL finish, but can also be used with diverse other metals, including aluminium and bronze. It can be used on plates, on shaped steel and pipes, as well as on welded products. Moreover, grind size can be altered by adjusting grit size.

With the PHL (vibration) finish, the random grind marks reflect light softly, creating a luxuriant shine. This chic and relaxed effect is exactly why the PHL finish is used so widely in both interior and exterior settings. The PHL finish also means that scratches and marks are comparatively less visible, making it ideal for high contact areas such as doors, handles, and counters.

■KIKUKAWA’s quality-focused PHL finishes

PHL is a commonly used finish for metal architectural materials and at KIKUKAWA, our strength in PHL lies in maintaining the highest quality regardless of material, shape, or combination. For example, when using a PHL finish over a large area, disparity in the finish within single and across multiple panels can be an issue. KIKUKAWA’s strict quality control makes it possible to achieve a consistent PHL finish across even large panels. Panels aside, the PHL finish can be applied flexibly to a variety of fittings and fixtures, regardless of shape. Our portfolio for this finish includes 6.8m long wall panels, round column covers with a maximum 7.5m allocation, and frames for large glass screens.

Finishing welded joints with PHL is a process that requires significant technical expertise. The polishing is carried out by highly-skilled craftspeople, who are able to create a beautiful finish with no noticeable discontinuity at the joints.

PHL can be combined with other surface finishes such as Coloured Stainless Steel, Anodization, and Sulfurization. At KIKUKAWA, we have developed various bespoke finishes in the process of meeting individual project specifications. We are best placed to propose solutions perfectly aligned to the nature of any given project.

Please consult with us if you are considering using a PHL finish on metal materials about the diverse options KIKUKAWA can offer.

Click here for our online inquiry form

■PHL (Vibration) Types

●PHL (Vibration)

A standard PHL (vibration) finish. Used across a diverse range of metal materials and shapes.

Project Gallery: Search by Finish: PHL

● Defined PHL

This finish is achieved using a rougher grind size than used for standard PHL (Vibration). The result is a more noticeably scattered reflection of light.

● Pearl Vibration

This finish features grind marks resembling countless tiny, overlapping circles. Compared to standard PHL, it is highly reflective and exudes glamour and luxury.

Project Gallery: Search by Finish: Pearl Vibration

■ Combining PHL (Vibration) with various materials and finishes

● Stainless Steel

The level of shine will depend on the base material chosen: 2A, BA, or mirror polished. Compared to PHL-finished 2B material, using PHL with BA and mirror polished materials will result in a more pronounced shine. Stainless steel is highly resistant to corrosion and comparatively resistant to rust, so it can be used in both interior and exterior settings with just a polished finish. It is possible, however, to also apply clear coatings according to the project specification.

We can also accommodate the use of PHL finishes on materials other than standard SUS304, including highly corrosion-resistant ferritic stainless steel and two-phase stainless steel.

Click below for examples from our Project Gallery

Project Gallery: Tokyo Midtown Hibiya

Metal Craft News: Entrance Crafted in Three-Dimensional Stainless Steel Panels

PHL + Coloured Stainless Steel

Our Coloured Stainless Steel finish is achieved with either a colour-forming oxide layer or a ceramic coating. Unlike paint, this can be combined with the distinctively metallic grind marks of PHL to great effect, revealing a myriad of beautiful colours besides that of the base material.

Click below to see finish samples

Finish Samples: Stainless Steel

KIKUKAWA’s Technology: Metal Products Using Coloured Stainless Steel

●Aluminium

Aluminium can create a light and airy ambiance, quite distinct from the luxuriance of stainless steel. When using aluminium in interior or exterior settings, treatments such as anodization or clear coatings must be applied to prevent progressive corrosion arising from polishing marks.

Defined PHL + Anodization (Alumite)

This finish combines anodization, a finish that enhances the intrinsic metallic qualities of aluminium, with the random grind marks of defined PHL. Bringing together the uniformity of anodization and the reflectivity of the PHL grind marks results in an elegant and tranquil shine.

Alumite (Anodization) involves a pretreatment in which the base material’s surface is dissolved with an etching solution. This makes the grind marks less conspicuous and is why, conventionally, these two finishes have not been used together. Despite this, KIKUKAWA has managed to combine these two finishes successfully by resolving various obstacles. As well as silver alumite, KIKUKAWA can work with secondary electrolytic colouring such as stain colours and black.

Click below for examples from our Project Gallery

Project Gallery: Ginza Station, Tokyo

Metal Craft News: Renovating with Vibration and Black Anodized Aluminium

Click below to see finish samples

Finish Samples: Aluminium

KIKUKAWA’s Technology: Anodization for Architectural Metal Construction Materials

● Bronze

Combining the opulent red and yellow tones of bronze with PHL grind marks creates an ambience of glamour. Clear coatings are applied as standard to prevent the changes in tone that commonly appear over time with copper alloys.

Click below for examples from our Project Gallery

Project Gallery: Artizon Museum, Ishibashi Foundation, Tokyo

Metal Craft News: Bespoke Copper Hood

PHL + Sulfurization

This finish involves using PHL (Vibration) on copper, bronze, or brass, followed by sulfurization and a clear coating. The random grind marks characteristic of the PHL finish introduces a non-uniformity into the sulfurization effect, creating a richer and more nuanced finish.

Click here to see finish samples

Finish Samples: Bronze

KIKUKAWA’s Technology: Sulfurization Finish

Click below to discover KIKUKAWA’s other polished or grinded finishes

KIKUKAWA’s Technologies: Polished or grinded finish

Aluminium ceiling panel finished in PHL + secondary electrolytic colouring (silver). This finish imparts an elegant air that invites light into the underground station building. (Ginza Station)

Left: Feature wall showcasing various stainless steel finishes. Three PHL finishes are featured, each achieved with a different grind size.

Right: Interior brass panels finished with PHL. The finish is flawlessly even despite the extended length of the panels (Artizon Museum, Tokyo)

Renovating a store façade with panels finished in a luxurious PHL + Coloured Stainless Steel (black).

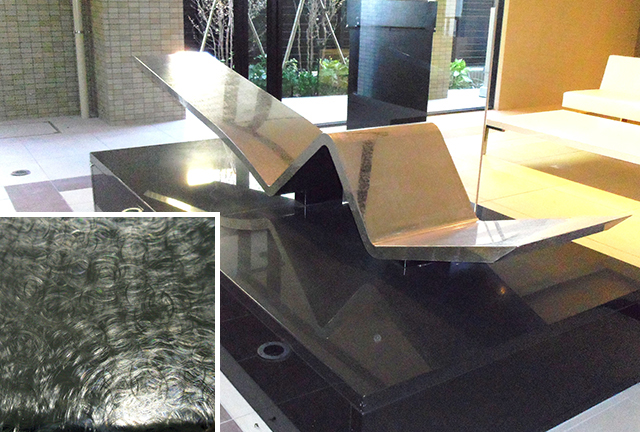

A stainless steel monument featuring a pearl vibration finish. The welded joints have been hand-finished by craftspeople.