We were involved in the construction of the exterior of a tenanted building in Kitashinchi, Osaka. The appearance of the building changes dramatically from day to night.

A perforated panel with a series of peaks and troughs. We devised an innovative method of fabricating the joints which also serve as folds.

A perforated panel with a series of peaks and troughs. We devised an innovative method of fabricating the joints which also serve as folds.

Top: A polyhedron-shaped entrance featuring beautiful edges and gorgeous lighting. Bottom: Wall art. The large arched panel to the rear is crafted in ‘Rough Tone Metal’.

Top: A polyhedron-shaped entrance featuring beautiful edges and gorgeous lighting. Bottom: Wall art. The large arched panel to the rear is crafted in ‘Rough Tone Metal’.

■ A stand-out three-dimensional façade in bustling central Osaka

G PLATE kitashinchi 8 is a nine-story tenanted building, with an innovative and eye-catching design, located in the middle of the restaurant and bar-packed downtown area of Kita Ward in Osaka. KIKUKAWA contributed to the creation of a striking three-dimensional façade that gives the building an imposing presence.

■ Three-dimensional perforation panels that looks striking when illuminated

From the third floor upwards, the building is wrapped in three-dimensional exterior panels, crafted in aluminium and forming a geometric pattern through perforations and repeating peaks and troughs. A total of 234 quadrilateral panel units are installed, in 26 rows of nine units. Each panel has been finished in a muted silver colour using a secondary electrolytic colourization process, the peak-and-trough design creates a shading effect that suggests multiple colours. Come night, the exterior is illuminated in colourful tones, bringing glamour to the building. The internal lights also seep through these perforated panels, giving an impression of transparency quite different to the building’s daytime look.

The bended panels are crafted in 2mm-thick aluminium. Each panel measures approximately one square meter (1m x 1m). The peaks and troughs run diagonally across each panel, and each panel has one plain section and three sections featuring perforation comprising 25mm-spaced square holes. KIKUKAWA fabricated full-size prototypes to facilitate discussion between the design and production teams; as a result, the initial design of the panel joints was altered to a fit that required less welding. This improved both the aesthetics of the panels and overall project efficiency. The centre panel in each row also functions as an emergency entry/exit. These panels have been designed to appear identical to the other panels while also functioning as doors.

Click here for more information on our perforation technology

■ Aluminium exterior panels forming a large polyhedral entrance

Visitors are welcomed to the building by an impressive entrance canopy for the first and second floors, clad in exterior panels and forming a polyhedron measuring 9.8m in width, 8m in height, and 2.8m in depth. The panels are finished in a pearl white fluororesin baked coating. Each bended panel is crafted in 2mm-thick aluminium with a standard size of 890mm by 890mm.

Grooves with a depth of 0.5mm were created along the diagonal lines on the panel surface. His process formed subtle line patterns. When placed together with the mirror-polished stainless steel trunking, attached to the panel joints, the panels form a lattice-like pattern. Small triangular acrylic panels, fitted with internal lights, are embedded at the panel corners. As the panels were to be installed on-site by a third-party contractor, the panel dimensions were carefully designed and adjusted in advance to ensure a perfect fit.

The key design challenge in this project was how to achieve the desired three-dimensional shape, including the substrate. We used 3D data to explore the complex fittings required, as well as to check the intricate shapes involved. We also created small-scale models using a 3D printer, which were used to enhance shared understanding among project stakeholders and with the on-site team. For panels with considerable depth, which consequently could not be installed using regular scaffolding, specific measures were taken to adapt the installation to these unusual shapes, such as preparing additional modified scaffolding boards.

■ Wall art crafted in ‘Rough Tone Metal’ panels

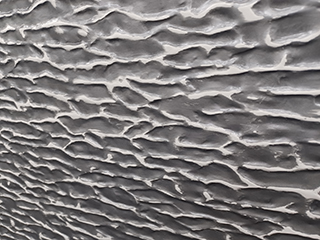

▲A ‘Rough Tone Metal’ surface

KIKUKAWA was also commissioned to fabricate a ‘Rough Tone Metal’ artwork to feature in a wall art panel installed next to the spiral staircase in the entrance hall. This plate is fabricated in aluminium but features the three-dimensional texture of cast metal. The panel used in this piece is an arch with a width of approx. 900mm and a length of approx. 2,500mm. The 1.5mm-thick aluminium has a unique uneven texture and is coating in a light grey colour that recalls calligraphy ink. ‘Rough Tone Metal’ products can reproduce the texture and solid feel of cast iron, in formats suitable for settings with weight restrictions, such as wall mountings and multi-panel pieces.

Click here for more information about ‘Rough Tone Metal’

■ Design and processing technology to achieve three-dimensional shapes

The key to this project was whether we could actually realise the architect’s sophisticated design. In this instance, the designer had faith in KIKUKAWA’s noted ability to transform design ideas into reality and the project was commissioned to us. This was a great opportunity to demonstrate our advanced technology, particularly in three-dimensional design, as well as our strengths in the fabrication of three-dimensional panels including angled shapes and polyhedrons. We ensure close collaboration among KIKUKAWA departments and we also take the initiative in communication with other contractors to ensure seamless on-site progress. Our clients were delighted with the result, commenting that “the product we received was of exceptional quality”.

| Product | Material | Metal Finishes or Metalwork |

|---|---|---|

| 3F and Above Exterior Panel |

Aluminium | Anodizaton (Electrolytic Colouring) Perforation |

| 1,2F Entrance Exterior Panel |

Aluminium | Fluororesin Baked Coating Milling |

| Wall Art Panel | Aluminium | Rough Tone Metal Special Painting |

| Project | G PLATE kitashinchi 8 |

|---|---|

| Client | SEIWA CORPORATION |

| Architect | design MIX |

| Contractor | SEIWA CORPORATION |

| Completion | 2023 |

| Location | Osaka-city, Osaka |