November 26, 2019

Implementing Various Shades of Black

Kikukawa is able to propose various metals and finishes based on the requirements of the project, with expertise from years of bespoke metal construction.

To show the diversity of the metal finishes available at Kikukawa, the following is a selection of black metal finishes.

Note that the colour – black – is not sufficient to select a finish: factors such as gloss level, the shade of the colour, texture or consistency affect the materials’ appearance and its applications. (Please note that the pictures may not fully capture the nuances or the texture of the finish – thus please confirm the finish with an actual sample.)

■Black Oxidized Coating

Projects requiring matte black finishes may want to consider this black oxidize coated steel.

Black oxidize coating is a chemically applied coat of oxidization, which prevents further oxidization and rust. As the coating process is applied under room temperature, the metal is not exposed to risks of heat-induced deformation or discoloration.

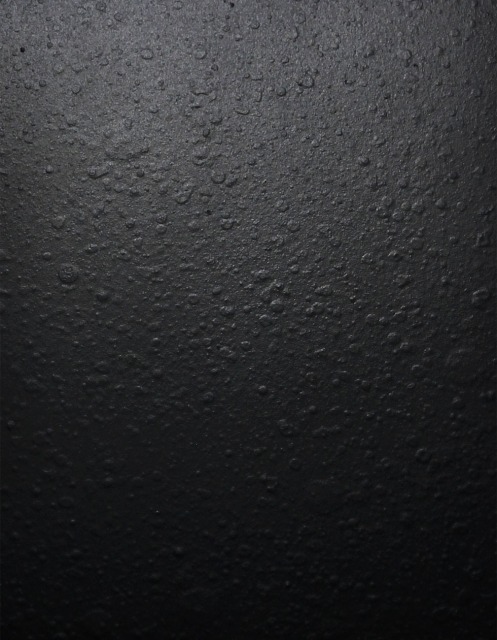

■Casted Paint (Matte Black)

This finish recreates the uneven surface of casted steel with paint. As the finish may be applied to non-casted products, a casted physique may be applied to products of shapes and sizes that are otherwise unavailable. This paint finish is also applicable to aluminium.

The flatness of the surface and gloss-level may be adjusted.

■Piano Black

By adjusting the flatness of the surface and applying a coat of high-gloss clear coating, the casted paint physique transforms into this high-end bespoke paint finish that is reminiscent of a grand piano. This finish uses urethane paint and is applicable to aluminium.

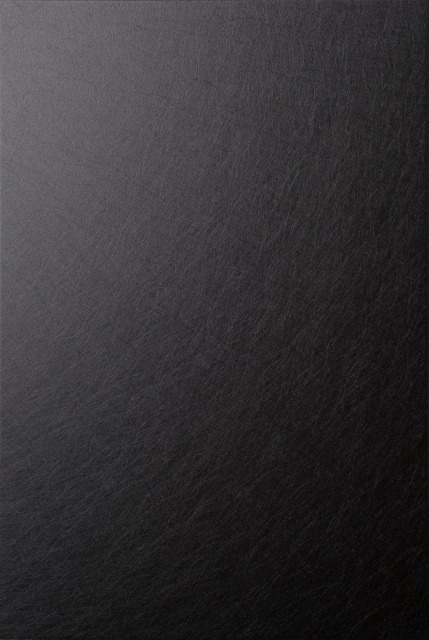

■Vibration Pattern Polishing and Anodization (Black)

For projects requiring metallic appearance that cannot be implemented with a painted finish, vibration (PHL) polished and anodized aluminium may be your choice.

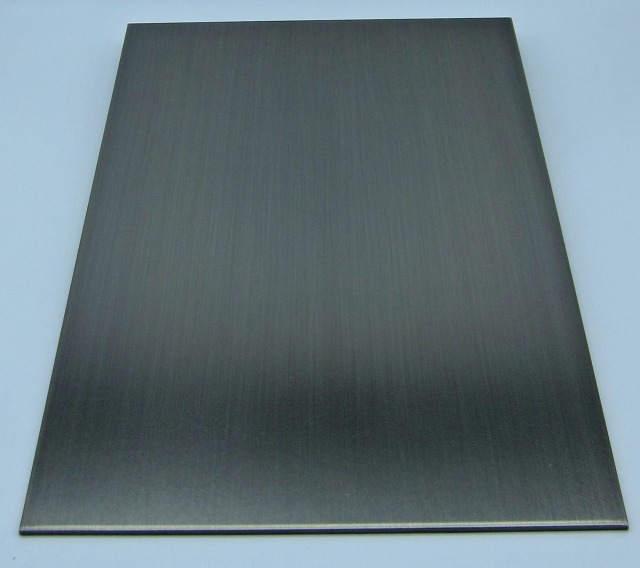

■Hairline Pattern Polishing and Black Nickel Plating

Projects requiring metallic textures with high resistance may want to consider the black nickel-plated and hairline polished stainless steel. As this finish creates a surface with natural hues of black, it is best for a context requiring inconsistent texture.

■Coloured Stainless Steel

Black stainless steel may also be actualized by colouring, which may be applied chemically, sputtering or electrolytic colouring.

■Sulfurization

For projects requiring a tint of black, and considering a high-end finish, sulfurization of bronze may be suitable. Bronze sulfurization is a process that recreates the rich brown textures of aging bronze by hand. By quality controlling the process, Kikukawa is able to provide various shades of dark brown.

Click here for more information on sulfurization

■Zinc Phosphate Coating

A tint of black with the metallic and stately texture of steel are available by applying zinc phosphate coating, a finish that chemically applies an insoluble crystalline layer. As this is a chemical process, the resulting tone and pattern vary depending on various factors including the composition of the material, thickness or shape.

Click here for more information on zinc phosphate coating

As shown, a wide range of ‘black’ metal finishes are available at Kikukawa. As experts in metal craftsmanship and construction, Kikukawa is able to select the most suitable finish as required by the project from the aesthetics, function to cost. We propose and provide comprehensive solutions to various metal constructions with our never-say-no spirit.

Please do not hesitate to contact us from the availability of the finish, its application to other consultations on metal constructions.