Staircase wall panels with Silky Blast

Blasting is a surface finish or treatment obtained by the impact of various blast media (materials) being propelled onto the surface of sheets or products.

With metal products, this finish is typically known as surface preparation to promote adhesion of paint coatings. If used as a surface finish, it was often associated with inconsistencies in colour or quality.

Kikukawa addressed these difficulties and elevated the treatment to a high-quality surface finish with its technology, craftsmanship, and expertise. “Silky Blast” is a series of bespoke blasting finish, named after its silk-like matte texture. This finish is applicable to external and internal constructions and is available in a wide range of coarseness and reflectivity.

Kikukawa’s “Silky Blast” can be applied to metals such as aluminium, bronze alloys, steel, and titanium. Applicable sizes and applicable material thickness depends on the blasting media and product shape, therefore, please consult us on the feasibility of the finish. Combinations with other metal-crafting technology can be accommodated.

| Main Features | -Many finishes possible by adjusting the blasting medium and its size -Maintains a metallic appearance -Accommodates bespoke textures |

|---|---|

| Applicable Materials | Metal -Steel -Stainless steel -Aluminium -Bronze -Titanium Minimum sheet thickness 0.5mm |

| Categories | Blast media -Glass beads -Zirconia -Sand -Alumina |

| Maximum Workable Size | 2500mm(W) x 6000mm(L) *Please consult us for any products over 1500mm(W) *For B-series: max. 1219mm (W), and max. material thickness is 2mm. |

Stainless Steel with Silky Blast finish.

■What is Blasting?

Blasting is a surface finish or treatment obtained by the impact of various blast media (materials) being propelled onto the surface of sheets or products.

The process is also known as bead blasting, sandblasting, abrasive blasting, automated blasting, shot blasting and more depending on the media or method.

By adjusting the blasting methodology and media, various textures can be achieved. For this reason, blasting technology is used in various industries including and not limited to aerospace, automobile, construction, foundry, ship-building, rail, and electronic components.

■Purpose of Blasting

The purpose of blasting ranges from smoothing, cleaning, polishing, descaling, deburring, and chipping. Typically, blasting is used for ceramics, glass, stone, and metals as a process to improve the aesthetics or functionality.

Types of blasting include automated (wheel) blasting, air blasting, and water (hydro-) blasting. In automated (wheel) blasting, the blasting medium is placed on a spinning wheel to propel it against the target object. Air blasting relies on compressed air to blast or suck the blasting media against the target object. Wet (hydro-) blasting involves the use of highly pressured stream of water to deliver the blasting media.

Each type is able to accommodate a wide range of blasting media, media size and media quantity to achieve various textures. For instance, using smaller media particles achieves smoother, finer textures while blasting larger media particles would leave greater impressions on the surface.

Other conditions that could affect the quality of the finish include blasting speed, intensity, and distance necessitating quality control expertise.

These textures have various applications. Coarser finishes are used to hide scratches, to deburr and/or to clean, while smoother finishes are applied to improve slipperiness. Everyday examples of blasting application include metallic nail files and frosted glass.

With metals, blasting was developed to remove paint coating, or as surface, preparation to improve adhesion of the paint coating. In recent years, it is also used as a surface finish. Coverage controlled blasting are used to engrave three-dimensional signage.

Applying a consistent blast is more straight-forward with flat sheet metals, however, the process becomes more challenging on curved, welded or small surfaces.

■Blasting Medium

Common blasting medium can include agricultural (such as peach pits or walnut shells), glass, metal, zirconia, alumina, and sand. Metal and ceramic medium tend to leave greater impressions while agricultural or glass medium leads to smoother surfaces.

With metal, common blasting medium is beads (glass), zirconia, sand, and alumina.

*Alumina: Also known as aluminium oxide. A substance made from bauxite to smelt aluminium.

** Zirconia: Also known as zirconium dioxide. A zircon based ceramic blasting media that is more resilient than glass. Not to be confused with zirconium silicate, or zircon, that is also known as the gem, matura diamond.

■Considerations When Choosing Blasting

Blasting can achieve various textures on a wide range of shapes and materials, thus it is useful for diverse purposes. Please consider the following before choosing this process as a metal surface finish.

・Blasting may interrupt protective coating or reduce corrosion resistive coating that existed. Plus, textured surfaces are more prone to fingerprints and more difficult to clean. Therefore, an additional coat of corrosion resistant coating or protective coating may be required.

・Blasted objects, especially thinner materials, may be susceptible to distortion. For projects with strict flatness requirements, correctional measures may be necessary.

・The quality of the blasted surface finish relies on the quality of the original surface material. As such, any dents, pores, bumps or scratches on the material should be addressed prior to blasting or a coarser finish may be more suitable.

・Different material lots may lead to inconsistencies in the colours of the blasted surface.

■Kikukawa’s Blasting

At Kikukawa, we provide and develop bespoke blasted finishes as required. Applicable materials include aluminium, stainless steel, bronze alloys, steel, titanium, and minimal applicable material thickness is 0.5mm. Applicable size is 2500mm(W) x 6000mm(L), however, we provide blasting finish to small screws to extra-large 18m panels. The most suitable type of blasting is chosen based on the requirement of the project, product shapes or blasting media. Thus variances in applicable sizes or applicable blast media may exist. Please consult us for confirmation or for more information.

- 1. “Silky Blast” Finish

“Silky Blast” is a series of bespoke finishes made possible by combining Kikukawa’s shot-blasting technology and craftsmanship. It was developed as a project-specific finish to satisfy a client’s design intent and is named after its silk-like matte texture.

The finish is obtained by blasting stainless steel surfaces with different materials; however, the quality and the consistency is ensured by Kikukawa’s technology and expertise. This elevates the surface treatment to a high-quality surface finish.

The finish is available in a wide range of coarseness and reflectivity; from smooth textures to pewter like dull finish. We also develop bespoke finish as required.

With stainless steel, this finish is applicable to exterior and interior constructions. Kikukawa provides blasted finish to small areas and thus is able to accommodate various shapes. Additionally, Kikukawa is able to apply an artificial layer of passivation coating to strengthen the natural properties of stainless steel and increase the longevity of the finish.

For pictures and more information on stainless steel finish samples, click here

- 2. Kikukawa’s Passivation Coating

Passivation is a naturally occurring protective coat that forms on the surface of stainless steel. Upon exposure to air, chromium within the material reacts with oxygen to form a thin film that gives stainless steel its corrosion-resistant properties. The thickness of the film is approximately 1nm*** (nano-meter), however, the composition of the bond is stable and strong and the coat quickly reforms when damaged.

This naturally occurring passivation coat may be weakened once blasting finish is applied. Kikukawa has the technology to artificially apply an additional coat of passivation so that the surface finish can be enjoyed for a longer period.

*** nm(nano-meter): 1 nanometer is one billionth of a meter or 10-9 meter.

- 3. Projects With Kikukawa’s Blasting

“Silky Blast” was developed to satisfy a client’s design intent and has been selected for various projects and products. From round column covers with minimal joints as pilotis, to the interior and exterior constructions of notable brands stores, Kikukawa has used this finish to realise various design intent. Here, we introduce a few examples.

To search for projects with “Silky Blast” finish, click here

□Stainless Steel

◆MIHO Art School

The bespoke finish, “2-Z+R10”, is featured in our collection of the stainless steel finish sample book.

The geometry of the façade brings to mind a fan fixed at a point. Formed with panels that stretch up to 18.5m in length, the panels are twisted into its own geometry.

With extra-wide and extra-long panels or thicker sheet materials, the quality of the sheet material tends to decline. To accommodate this, the selected finish is coarser and emits a subdued shine.

Click here for more information on MIHO Art School

◆The Japanese Sword Museum

The concept of this project, a Japanese sword, was implemented with “Silky Blast” finish. The gentle shine and reflection of the finish lead to a stately and refined physique.

Click here for more information on The Japanese Sword Museum

◆Tokyo Station, Marunouchi Building

Stainless steel round column covers over 10 meters stretches to the ceiling of the dome in this station building. Given the heavy traffic in the area, the lower column covers are coated with Kikukawa’s artificial passivation coating to increase the longevity of the finish. The consistent finish and considerations to the project requirements are apparent in this example.

Click here for more information on Tokyo Station, Marunouchi Building

◆Chukyo University, Nagoya Campus

The giant monument named “Pterosaur’s egg” is formed by a giant metal egg and a leg hanging from the ceiling. To finish the stainless steel portion of the egg, the metal had to be three-dimensionally formed then blasted for its complex shape and size. As blast finishing a curved surface uniformly requires great care and expertise, this was a challenging project that has helped to further our expertise.

For more information on Chukyo University, Nagoya Campus

□Other Metals

◇Aluminium

The interior panels surrounding the spiral staircase, and the ceiling of a particular brands’ research facility are finished with “Silky Blast.” Typically, aluminium sheets become cloudy when blasted, however by using bright aluminium alloy and applying a specialized polish, a uniform and gentle reflective finish were actualised.

◇National Showa Memorial Museum (Titanium)

National Showa Memorial Museum commemorates and captures the livelihood of the Japanese people during and after the Second World War. To preserve the documents and collected items within the building, the façade was designed with minimal openings and windows to limit sunlight. The alumina blast finished exteriors form a unique geometry that highlights vertical and horizontal lines of the design.

■Please consult us

Kikukawa provides a high-quality bespoke blasted finish with various blasting media onto a wide range of products by combining our metal-craftsmanship and cutting-edge technology. For panels, doors, joints or decorative hard-wares, as well as interior and exterior constructions, this finish is able to provide an elegant metallic physique. We are also able to accommodate a wide range of coarseness and reflectivity. Please contact us for more information.

Stainless Steel with Silky Blast finish.

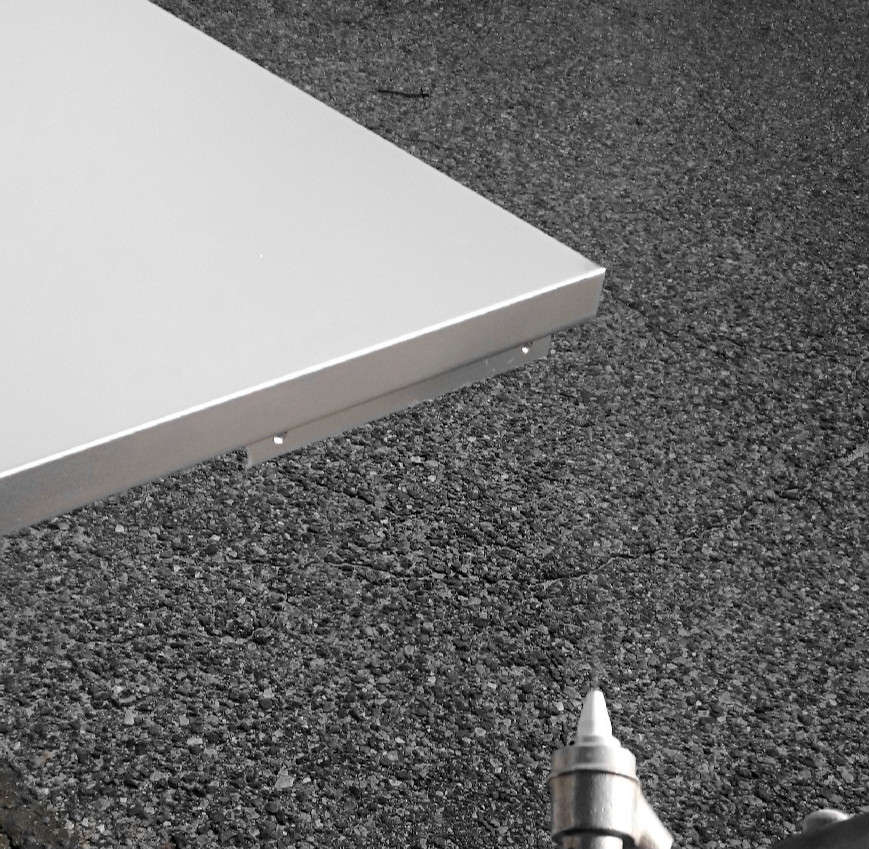

Passivation coating exposure test. After four years of exposure, the right half was coated with Kikukawa's passivation coating treatment. (Photographed Sept. 2018)

Blasting can be combined with other metal-work

Silky Blasting the edge of a panel with air blasting