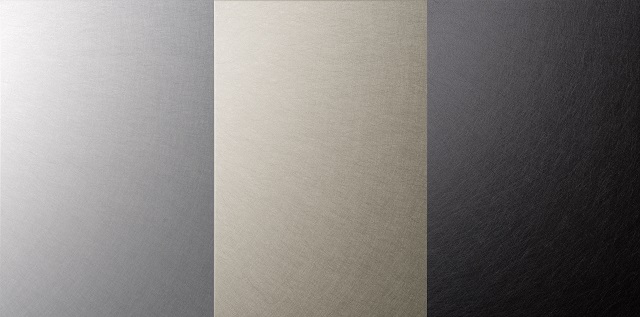

Defined PHL (vibration) and anodizing: from the left, silver, champagne gold and black

Anodization is one of the main finishes used for aluminium within architecture, both interior and exterior, for its aesthetics and function.

From the typical anodization to the bespoke anodized finishes, Kikukawa has the expertise in comprehensive quality control and the established partnerships with anodizing companies to implement high quality anodized aluminium constructions. In addition, Kikukawa explores and develops new anodization technology through combinations with other metal crafting technology as required. This includes combining of grinding (polishing) such as PHL (vibration), or the electro-polished highly reflective aluminium.

| Main Features | ・High quality (consistent) anodization ・Ability to procure from the lot to ensure consistency ・Accommodates specialized aluminium alloys such as highly reflective aluminium (bright aluminium) ・Accommodates combinations with other finishes (including polished or grinded finish) ・Accommodates bespoke or newly developed anodization ・Outsized panels (extra-long, extra-wide) ・Combinations with dual-curving or R curving |

|---|---|

| Applicable Materials | ・Aluminium (Sheet: A1100-H14, Extrusions: A6063-T5) ・Highly reflective (bright) aluminium (A5110AP-H24) ・Other aluminium alloys |

| Categories | ・Sulfuric anodization (Type II and III) ・Sulfuric anodization and electrophoretic colour depositing (metallic colours including shades of bronze, black and more) ・Matte finish (including removal of die marks) ・Composite anodizing (anodization and electrophoretic clear coating) ・Dyeing and anodizing (gold and more) ・Anodized highly reflective aluminium (also known as bright aluminium) ・Grinding (polishing) and anodizing finish Please consult us on accommodations of other anodizing. |

| Maximum Workable Size | Maximum: W1800mm x L6000mm Please consult us on products exceeding the size listed above |

| Remarks | Size or usage limitations vary depending on the project requirements, area of use (interior / exterior), aluminium alloy, selected finish, shape or the metalworking required. To select the most suitable finish, please consult us prior to your final selection. Please also note that Kikukawa does not offer anodizing by itself. |

Exterior of Sumida Hokusai Museum: Electropolished and anodized highly reflective aluminium

■What is Anodization?

Anodization is an electrolytic passivation coating process used to create the natural oxide layer on the surface of a particular metal.

For aluminium, anodization creates a microscopic layer on the surface of a solution dipped aluminium by passing a current. This surface treatment is applied to improve the materials’ corrosion and abrasion resistance.

Within the architectural industry, aluminium is favored for its light weight and workability, however it cannot be used without any surface treatment. Anodization is as frequently chosen option for its functionality and ability to implement metallic textures.

■Kikukawa’s Quality Control in Anodization

Anodization creates a new anodic layer, however slight changes in the composition of the material or the solution could disrupt the consistency of the resulting colour.

Based on established partnerships with metal sheet fabricators and anodizing companies, Kikukawa controls the quality from the lot procurement, thus minimizing the risk of inconsistency in colour. We also control the processes before and after the anodizing for quality, including the thickness of the coat.

This quality control expertise is applied to typical finishes and newly developed finishes such as highly reflective aluminium (bright aluminium) finishes or grinded (polished) and anodized finishes.

■Diversity of Anodization

There is a great diversity in anodization used in metal construction; from those commonly used in to bespoke anodization finishes. Listed below are a selection of the anodization processes.

Click here to view the aluminium finish samples

【Common Anodizing】

○ Sulfuric Anodizing (Sulfuric Acid Anodization / Silver Anodization / Type II and III)

One of the most commonly used anodizing methodology, sulfuric anodization is achieved by sinking the material in a sulfuric acid solution, and passing a current. The resulting anodic layer is colourless (the silver colour comes from the material), and provides corrosion and abrasion resistance. This treatment is often used as a base layer prior to dyeing or electrophoretic deposited coating.

○ Sulfuric Anodizing and Electrophoretic Colour Depositing

The sulfuric anodized layer created with sulfuric acid anodization (or sulfuric anodizing) has microscopic pores on its surface. The additional electrolytic colouring process fills these pores with oxide or hydroxide of metallic salt such as tin or nickel. As the salt in the solution are metallic, the available colours are hues of metal such as champagne gold, bronze, or black.

○ Matte Finishing

Aluminium materials tend to have die marks (lines) in the longitudinal direction from its fabrication process. Matte finishing chemically removes these die marks and creates an anodic layer with a texture of low gloss reminiscent of bead blasted finish.

This process is applied prior to the sulfuric acid anodization process, before or after the etching process which removes any dirt or grease on the naturally occurring anodic layer.

○ Sealing

Sealing is a process that closes the porous anodic layer resulting from the sulfuric acid anodization. Without this step, the anodic coating is highly absorbent of water, dirt or grease. Therefore, this step is necessary if other porous filling coatings will not be applied.

○ Composite Anodizing (Anodization and Electrophoretic Deposited Clear Coating)

Regardless of the type of anodization process applied, a final touch of an electrophoretic deposited acrylic clear coating improves the durability of the anodization. This methodology is becoming a new standard for products of exterior use, considering its longevity and resistance, in consideration of increasing environmental risks such as acidic rain or ultraviolet rays.

○ Dyeing (Sulfuric Anodization, Dyeing and Electrophoretic Deposited Clear Coating)

To apply bright colours to aluminium, sulfuric anodized aluminium are run in a dyebath, then sealed with electrophoretic deposited clear coating, otherwise known as the sealing process.

Available colours include gold, red, blue and black. For exterior use, only gold is available due to limitations in weather resistibility.

【Bespoke or Unique Anodizing】

○ Electropolishing and Anodizing

Applied to flatten and improve the gloss level of aluminium. The surface of the workpiece is dissolved and removed by placing the aluminium in a solution filled tank, and passing a current. The polished workpiece is then typically sulfuric anodized.

○ Chemical Polishing and Anodizing

Applied to improve the gloss level of aluminium. Obtained by submerging the aluminium in chemical solutions, such as acidic or alkaline solutions with salt, which dissolves the surface of the aluminium. The polished workpiece is then typically sulfuric anodized.

○ Anodizing Highly Reflective Aluminium (Bright Aluminium)

Highly reflective aluminium (bright aluminium), A5110AP-H24, is a specific type of aluminium alloy that has a higher gloss level than the regularly used aluminium alloy. By electropolishing these alloys and anodizing, the resulting gloss level is one that achieves a gentle reflection different than that of mirror-finished stainless steel.

At Kikukawa, we also provide alternative options in gloss level and subsequently the cost. For example, we have established a methodology to offer highly reflective anodized aluminium without the electropolishing process.

○ Defined PHL (Vibration) and Anodizing

Anodizing that fully showcases the grinding/polishing patterns on aluminium. The grinded/polished materials create a different texture from simply anodized aluminium; a chic ambiance of diffused reflection.

Prior to the establishment of this finish, combining grinded/polished finish and anodization was considered unsuitable as the etching process prior to the anodization tends to obscure the grinding patterns. Kikukawa overcame these difficulties to realize projects that fully showcases the beauty of the grinding pattern and anodization.

○ Anodizing and High Gloss Clear Coating

By applying a high gloss clear coating after anodization, this finish creates a high-end texture that reflects its surroundings. An example of this is the application of high gloss clear coating after sulfuric anodization and black electrophoretic depositing, which creates a piano like dark and glossy texture.

○ Bespoke Combinations of Finishes and Anodization

At Kikukawa, we develop and provide new patterns or combinations of metal craft finishing and anodizing as required. For instance, we have implemented concrete-like textures by combining Tsuchime (hammertone), etching and anodization.

Click here to view the concrete-like textured finish sample

■Examples of Kikukawa Projects with Anodization

○ Expanded Metal Façade with Anodizing [Kikukawa Group Tokyo Office]

Here is an example of anodized expanded metal façade that draws a smooth curvature. In comparison to paint coated finish, anodization of panels with openings, such as expanded metals, enjoy benefits such as the reduction of sharp edges through the etching process, or the reduction in fabrication lead time as the treatment can be applied on both sides of the panel at once.

Click here to find out more about the project, Kikukawa Group Tokyo Office

〇 A Façade of Highly Reflective Aluminium [Sumida Hokusai Museum]

To implement a design concept, “a façade that gently reflects the surrounding scenery”, the museum is covered with electro polished and anodized highly reflective aluminium (bright aluminium) panels.

There are over 427 panels of varying geometry, maximum panel size being 1400mm (W) by 5600mm (H), each finished consistently. This project is attracting attention since its completion, and there is a growing demand for this alloy and finish.

Click here to find out more about Sumida Hokusai Museum

〇 Golden Trails of Cloud by Gold Dyed and Anodized Highly Reflective Aluminium [Yakushiji Temple, Jikido Hall]

The divine cloud spreading from the ‘Illustration of the Pure Land of Amida’ is expressed by a design ceiling finished with gold dyed and anodized highly reflective aluminium. The ethereal space implements the client’s intent to create ‘a piece of architecture that would be passed down the generations.’

Click here to find out more about Yakushiji Temple, Jikido Hall

〇 Corrugated Spandrels with Die Marks [COS GINZA]

In a corner of Ginza Marronier Street stands ‘COS GINZA’ with a corrugated spandrel façade. The extruded surface has die marks to implement the metallic and sharp ambiance. The textured façade changes its expressions under natural lighting, and stands as a unique building amongst Ginza, a place of creative architecture.

Click here to find out more about COS Ginza

〇 Defined PHL (Vibration) and Anodizing [Tokyo Metropolitan Teien Art Museum]

The additional elevator tower is lined with a newly developed bespoke finish ‘defined PHL and silver anodization’. Unlike the uniform texture of typical anodization, this finish creates a unique ambiance of diffused reflection.

Click here to find out more about Tokyo Metropolitan Teien Art Museum

〇 Outsized Matte Anodized Exterior [Fuchu City Medical Association Hall]

The typical size of the panel that surrounds the 470㎡ exterior of this new hall is 1500mm (W) by 5300mm (L). The matte anodized finish creates a simple yet stately ambiance.

Click here to find out more about Fuchu City Medical Association Hall

〇 Electropolished and Anodized Aluminium / Highly Reflective Aluminium [Osaka University Arts, Arts & Science Department]

To find the perfect shade of reflection, Kikukawa provided varying finish samples for this project from differentiation in material, and anodization methodology. Depending on the area of use and the required shade, the electropolished and anodized aluminium or highly reflective aluminium is interchangeably used.

Click here to find out more about Osaka University Arts, Arts & Science Department

〇 Contrasting the Anodizing and Metallic Paint Coating [Sundai Preparatory School, Kashiwa]

Central to the design intent was a brilliant-cut diamond, a simile to students achieving their full potential through learning. The façade employs extra-long triangular panels of maximum 1450mm (H) and 6000mm (L), interchangeably finished with anodizing or metallic paint coating. This, and the perforations on the south side creates a unique façade.

Click here to find out more about Sundai Preparatory School, Kashiwa

◇◇◇

Other examples of anodized projects can be viewed through the photos on this page.

・Picture 3 – A chic entrance; ceiling and column panels finished with anodizing, black electrophoretic depositing and high gloss clear coating.

・Picture 4 – To fully showcase the neon lighting on top and below the panels, chemical polishing and anodizing finish was selected.

・Picture 5 – To express the unique characteristic of the brand, cuboid louvres finished interchangeably with silver and gold anodization is used.

*Other Anodized Kikukawa Projects

Click here to find out more about projects with anodizing

Click here to find out more about projects with highly reflective aluminium (bright aluminium)

■Kikukawa’s Strengths

Kikukawa’s strength is expressed through our company philosophy of ‘One Stop Solution’ and ‘Never Say No’. Our ability to provide comprehensive solutions and control the quality throughout the fabrication process allows us to respond to a variety of requests in designs, shapes and sizes.

New combinations of anodization, and other finishes such as grinding or perforations are developed to fully implement the design.

Please do not hesitate to contact us on architectural projects with anodization including consultation on feasibility and design.

Exterior of Sumida Hokusai Museum: Electropolished and anodized highly reflective aluminium

Office entrance ceiling and columns: anodizing, black electrophoretic deposited and high gloss clear coated

Chemically polished and anodized facade

Cuboid louvres finished with silver and gold anodization