The Sumida Hokusai Museum in Tokyo. This project was a catalyst in driving up demand for bright anodized panels.

Bright anodization is a distinct finish that makes the most of aluminium’s soft aura and boasts a subtle shine, quite unlike that of polished stainless steel. The way in which it gently reflects the surrounding scenery makes it ideal for bringing sophistication and differentiation to any design. When combined with aluminium polishing or used with coloured alumite alloys, this finish is perfect for meeting diverse needs and achieving highly unique designs. We can propose the best solution for any project, according to individual requirements.

The Sumida Hokusai Museum, completed in 2016, is cladded on all sides with exterior panels made by Kikukawa. The panels prompted an enormous response, and ever since there has been a spike in demand for panels finished with bright dip anodization. Fabricating the sheer volume of coloured bright anodized exterior panels required to clad the entire museum was an unparalleled undertaking. The experienced enabled Kikukawa to build up an unrivalled level of know-how, now manifested as outstanding technical expertise. Our dedication to quality means that we are able to offer products with minimal levels of colour unevenness.

Project Gallery: Sumida Hokusai Museum

| Main Features | -Strict quality management to ensure minimal colour unevenness -Strong ability to procure high quality materials (lot management) -Can be combined with a wide range of anodization treatments and polishing finishes |

|---|---|

| Applicable Materials | Luminous aluminium alloy (A5110AP) |

| Categories | -Silver anodized aluminium (primary electrolytic polishing) -Secondary electrolytic colourization (e.g. champagne gold, bronze, stainless color ) -Colour anodized aluminium (e.g. gold) -Polishing & anodic oxidation coating -KIKUKAWA’s original finishing series Alumiére® |

| Maximum Workable Size | thickness:1.5㎜~3.0㎜ max.1600㎜(W)×6000㎜(L) (Alumiére®:max.1200㎜(W)×4000㎜(L) ) *Please consult us for any products over this size |

| Remarks | This is a custom-made material, so please contact us in the first instance. Please note that we do not accept sale-only assignments for bright anodized materials. |

The subtle shine of the bright anodized panels gently reflects the surrounding scenery.

(Left) Bright anodized external panels fabricated using bright aluminium alloy (Sumida Hokusai Museum)

(Right) Wall panels fabricated by applying a reflectivity-enhancing treatment to a base material of pure aluminium (Arts and Science Department, Osaka University of Arts)

■What is bright anodization?

Bright anodization is an anodizing treatment applied to luminous aluminium alloy (A5110AP), a particular kind of highly reflective aluminium. The base material is first subjected to a reflectivity-enhancing treatment, which smooths the surface, then an anodizing treatment is applied to heighten luminosity. The resulting gentle shine, entirely different to that of polished stainless steel, adds significant value to aluminium as a building material.

Anodization for Architectural Metal Constructions

■Alumiére®

Kikukawa was quick to note the growing interest in achieving metallic shine finishes for aluminium and, in response, developed Alumiére®, an innovative finish arising from Kikukawa’s proven success in the fabrication of bright alloy panels. Alumiére® is an original Kikukawa building material that is highly versatile, since it can be used from small quantities. It was developed for interior use and boasts a strong line-up of options for shine, coating, and texture, all of which can be freely combined. Going forward, Kikukawa intends to make further additions to this line-up. Alumiére® can also be used in external settings with the application of a composite coating. Shine and maximum workable size will depend on the options chosen, and clients can select Alumiére® or conventional bright alloy panels as required.

Click here to learn more about Alumiére®

Click here for our online inquiry form

■Bright Anodization by KIKUKAWA

●Quality Management

Even among the various colourization techniques available, coloured bright anodization is particularly challenging. Kikukawa, however, has the all-round strength required to overcome this, rooted in its time-honed quality management know-how and strong collaborative relationships with alumite manufacturers. This strength enables us to achieve high-quality bright alloy products which are both beautiful and functional, and have minimal colour unevenness. In addition, the procurement of the specialist materials required for bright alloys can be a challenge. Kikukawa is able to eliminate the risk of colour variation caused by materials through strict lot management and quality management, made possible by long-held relationships of trust with our materials manufacturers. Even throughout the processes before and after anodization, Kikukawa operates a quality management system based on our extensive know-how to ensure an uncompromising level of quality in colour and tone. The same refusal to comprise applies to the management of film treatments, which are key to product functionality and performance.

These same quality management systems are applied to projects involving the installation of multiple, continuous exterior panels or large panels, as seen most notably in the Sumida Hokusai Museum.

●Adjusting shine and cost-reducing proposals

Making adjustments to the reflectivity-enhancing treatment makes it possible to control the level of shine, in accordance with design requirements and surrounding conditions. In addition, clients can reduce costs by opting for a finishes with lower levels of shine than that achieved with bright anodization and colourization. These include the B-E1 finish*, which is the result of developing a treatment technique that omits the reflectivity-enhancing treatment process while still making the best of the distinctive colour of bright aluminium alloy, or a type of finish in which a reflectivity-enhancing treatment is applied to pure aluminium (A1100).

Kikukawa can offer a range of choices and proposals according to your needs, including Alumiére® and many other options.

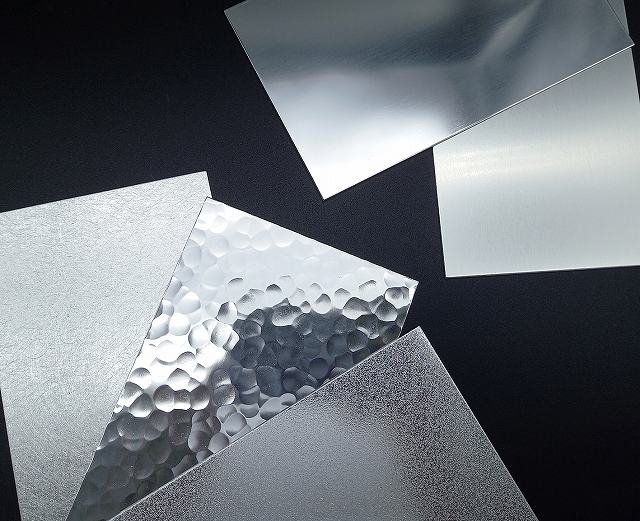

*See below for illustrative images of B-E1 and our other bright alloys.

Kikukawa’s Finish Samples-Aluminium

●Diverse variations

Kikukawa can combine anodization options and polishing finishes in accordance with client needs. At the Jikido Hall of the Yakushiji Temple in Nara, the brief was to create a solemn and majestic space with a gentle golden glow and light reflection. We achieved this through the use of gold dye anodized bright aluminium.

As can be seen in image 4, anodization can also be combined with a pearl vibration finish. The diffused reflection of this grinded finish sparkles brilliantly, showcasing the metallic feel of the material.

Project Gallery: Yakushiji Temple – Jikido Hall

■ KIKUKAWA’s unrivalled adaptability and proposal capabilities with bright anodization

KIKUKAWA’s strength is that we offer a one-stop solution to clients. From specifications for bright anodization, to comprehensive decisions and proposals on design, shape, and size, we can offer solutions perfectly aligned to your needs. For example, when determining the specifications for the Arts and Science Department building at Osaka University of Arts, we presented the client with a wide variety of coloured samples, each processed in a different way and with the corresponding cost indicated. We have also adjusted the shine quality of materials by location within individual projects.

Project Gallery: Osaka University of Arts, Arts & Science Dept.

We are committed to meeting client requests, be that to combine a certain polishing finish with a certain embossing process, or to use a high-shine aluminium material in a new way.

If you are considering using high-shine aluminum building materials, or you are finding such use a challenge, please contact us to discuss your needs.

The subtle shine of the bright anodized panels gently reflects the surrounding scenery.

(Left) Bright anodized external panels fabricated using bright aluminium alloy (Sumida Hokusai Museum)

(Right) Wall panels fabricated by applying a reflectivity-enhancing treatment to a base material of pure aluminium (Arts and Science Department, Osaka University of Arts)

Examples of our Alumiére® line-up.

Panels finished with pearl vibration and bright anodization, installed in the toilets at Ginza Station, Tokyo.

(Top) External toilet panels (Bottom) Use on partition walls, individual cubicle walls, and walls behind mirrors.

A Shinjuku office building with an updated look, thanks to the use of bright anodized panels on its exterior.