Mirror Finish

Diamond shaped sharp edge bent panel (vertical) and corrugated bending (horizontal)

Using various bending machines and dies, expertise and craftsmanship, KIKUKAWA is able to provide diverse bending needs. Complex or bespoke bending such as deep bending, sharp-edge bending, roll bending, step bending and taper bending as well as over-sized and extra-long bending are amongst the bending needs that we have previously actualised. Maximum workable size is 8000mm(L), with workable materials including steel, stainless steel, aluminium, bronze alloy, up to 6mm thickness. By combining this with other metal-crafting technology, KIKUKAWA is able to realise various designs and metalworks.

| Main Features | -Over-sized, extra long bending possible -Complex, bespoke and 3D shapes possible |

|---|---|

| Name/Type | -Bending machine -NC press brake -Metalwork bender |

| Applicable Materials | -Stainless Steel -Steel -Aluminium -Bronze (Copper Alloys) -Titanium Maximum thickness 6mm *Please consult us as each bend has different limitations |

| Categories | -Sharp-edge bending -Deep bending -R bending (curvatures) -Corrugated bending |

| Maximum Workable Size | 1600-2000mm(W) x 8000mm(L) *Please consult us for any products over this size |

Planer bending (left) and sharp edge bending (right)

■Bending Technology

- 1) Bender precision and diversity

KIKUKAWA holds over 10 bending machine and 30 dies, including an 8m bender and dies for R bending and deep bending. This, in combination with metal-crafting expertise and craftsmanship, allows KIKUKAWA to undertake various high-quality bending.

This includes bending that would be difficult with design data and machinery alone – such as curtain-like corrugated bending. Based on years of experience, our machine and craftsmen are able to materialise folds that are atypical in ready-made products.

- 2) Kikukawa’s bending expertise

To ensure the quality of the bend, KIKUKAWA’ s craftsmen utilise their knowledge and experience to select the best bending machine, die and procedure. Previous bending data is taken, sorted and used to further our technology for similar bends in the future.

- 3) Kikukawa’s Metal-Craft

As a metal-crafter that deals with various metals, Kikukawa provides a combination of metal-crafting services such as perforations, laser cutting and planning as well as welding, assemblying and finishing. As a bespoke metalworker, Kikukawa handles various designs from small lot productions to bespoke products.

- 4) Kikukawa’s challenge

As a bespoke metalworker, Kikukawa faces various new challenges on a daily basis. To answer the changing demand, Kikukawa is continuously experimenting and researching ways to further its current metal-crafting abilities.

■Bending Types

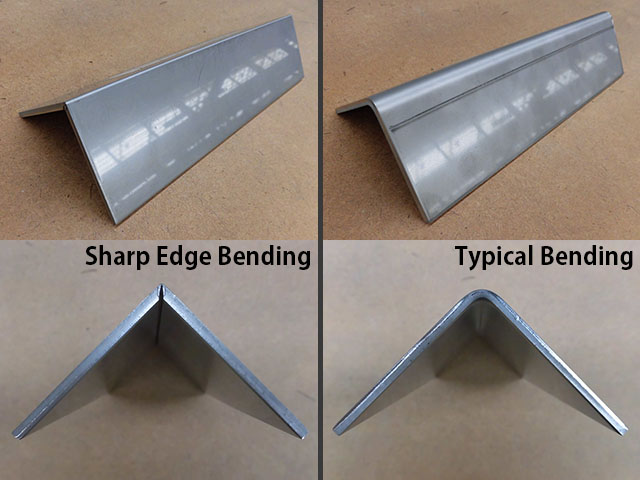

- 1) Sharp-edged corners

Bent sheet metals typically have rounded corners. To counter this, Kikukawa combines a planing process. From previous bending data, Kikukawa has refined its technology to actualise a sharp edge with precise, high-quality bending.

- 2) Deep bending

With special bending machines and made-to-order dies, Kikukawa is able to actualise deep bending. This allows us to take on projects with designs or product sizes that usually require extrusions, or those with small lots that do not fulfil the minimal requirement for extrusions.

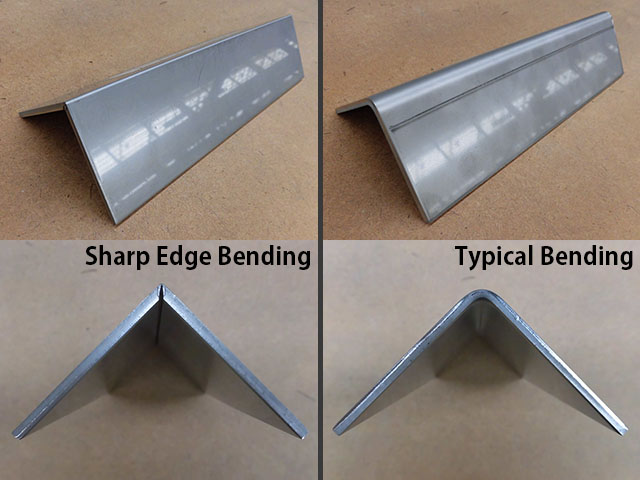

- 3) Corrugated bending

Soft curtain-like folds can be fabricated with Kikukawa’s expertise and craftsmanship. The geometry of the curves is read from the computer for production. At Kikukawa, we are able to manage small lot productions, fold designs that are not readily available, as well as those that require perforations and laser cutting.

We have also provided tapered corrugated bending.

- 4) Curved (R) bending

Using bespoke dies, Kikukawa is able to fabricate high-quality curves without bending traces.

Curved bending for cones, small curves, precise bending or oval shapes are amongst the products we are able to actualise.

- 5) Over-sized, extra-long bending

The 8m bending machine allows the fabrication of over-sized or extra-long panels. With it, we are able to realise designs with minimal joints.

For more details, click here

8m Bender

■Please Consult Us

Kikukawa is able to accommodate designs that require complex metal-crafting technology, small lots and those that do not fulfil the required lot for extrusions.

With our expertise and cutting-edge technology, we choose the most suitable fabrication method and procedure depending on the material, finish and difficulty of the bend. From consultation to fabrication feasibility, please do not hesitate to contact us.

For more information on metalworking capabilities, click here

Custom Metalwork

To make an inquiry, click here

Contact Us

Planer bending (left) and sharp edge bending (right)

Curtain-like Folds (Corrugated Bending)

R bent long bronze panels

Tapered Corrugated Bending