Stainless fittings and edgings in HL+Chemical Colouring (Gold) : a luxury feel is evoked by illuminating the structure in interference colours

Coloured stainless steel adds new value to stainless steel, a material already renowned for its superlative properties. Coloured stainless steel highlights surface finishes while softening the inherent coldness and sharpness of stainless steel, making it ideal for bringing depth and warmth to both interior and exterior panels and fittings. Coloured stainless steel also features regularly in high-impact designs intended to evoke a sense of luxury.

The Reiyukai Headquarters, completed in 1975 in Minato Ward, Tokyo, was the first structure in Japan to make large-scale use of coloured stainless steel. Since then, KIKUKAWA has drawn upon our robust know-how in quality management to establish the technical capabilities needed to ensure that our coloured stainless steel is a perfect balance of beauty and functionality. We are committed to exploring new challenges and to offering optimal proposals through the development of new combinations that will allow us to meet our clients’ wishes.

Click here to read about the Reiyukai Headquarters in our Project Gallery

| Main Features | -Can be combined with a wide range of polished finished surface -Careful management of smoothness and reflection when used with mirror polished bases -Can propose coloured stainless steel finishes or alternative solutions as required Etc. |

|---|---|

| Applicable Materials | SUS304 |

| Categories | -Chemical colouring: KC-Colour -Physical vapour deposition (PVD, sputtering): KS-Coating *We can also suggest alternative finishes. |

| Maximum Workable Size | -Chemical colouring: Max. W1200mm x L5000mm (up to 120kg) -PVD: Max. W1200mm x L4000mm (up to 120kg) |

| Remarks | Stainless steel materials come with limitations depending on shape and how they have been processed. Please contact us to discuss if you are interested in using coloured stainless steel. |

The Reiyukai Headquarters, completed in 1975: the main hall features ceiling panels in Chemical Colouring (Gold), fabricated using molding press technology

■What is Coloured Stainless Steel?

Coloured stainless steel is a finish that changes the colour of stainless steel, thereby enhancing a material which has excellent corrosion resistance and strength and which can be polished up to achieve a beautiful metallic gleam. Rather than the standard monochromatic silver, this finish imparts stainless steel with a myriad of colours, together with warmth and softness, thereby enhancing any design in which it is used. Coloured stainless steel can also be used as an alternative to bronze products when facing issues with procurement or to ensure adequate strength.

Coloured stainless steel is coated either with an ultra-thin oxide layer or a ceramic coating, both of which boast outstanding performance in weather resistance and corrosion resistance.

■Quality Control for Coloured Stainless Steel

Coloured stainless steel is affected by the texture of the base material, which means that there may be inconsistencies in the colour of the finish if there are even minute differences in the components used to produce the finish. At KIKUKAWA, we operate strict lot management and quality control, rooted in long-standing relationships of trust with our component suppliers. This has allowed us to eliminate the risk of colour variation arising from inconsistency in components. Our painstaking management framework is what enables us to guarantee quality and consistency in colour. Furthermore, for flat panels that will reflect surroundings and light sources, we can design, manufacture, and install panels with a high level of smoothness.

■KIKUKAWA’s Adaptability

KIKUKAWA is committed to offering a “One Stop Solution” and to take on challenges with our “Never Say No” ethos. Our integrated system, which incorporates all stages from design to construction, allows us to make comprehensive decisions covering design, shape, and size, and to develop optimal proposals for our clients.

Coloured stainless steel comes with various limitations, including colour types and processing methods. As such, KIKUKAWA may recommend the use of Colour Clear Coating, particularly for interior spaces. Please consult with us about what you would like to achieve and we will recommend best finish to suit your ideas and project. We are able to offer a wide range of combinations of polishing processes and desired colours, as well as developing bespoke solutions for specific installation and design requirement. For example, our suggestion of using black nickel plating with an HL finish was selected by a client looking to achieve a finish that evoked “ink running across the material”.

We are committed to doing whatever we can to meet our clients’ wishes, be that developing new combinations which incorporate polished finishes or etching processes, or innovating to create coloration that highlights the distinct material properties of metal.

If you are considering using coloured stainless steel products in your project, or if you have any questions about these products, please get in touch to discuss how we can help you.

Click here for our Inquiry Form

Click here to see examples of Coloured Stainless Steel in use in our Project Gallery

■Types of Coloured Stainless Steel

●Chemical Colouring (Inco method): KC-Colour

This method involves oxidizing stainless steel in a solution; the resulting oxide layer creates a colour effect. It was developed at the Birmingham-located Research and Development Centre of Inco Europe Ltd., and is therefore known as the Inco method. Just as bubbles appear rainbow-coloured when illuminated by light, so the processed stainless steel will seem to shimmer with a myriad of colours, thanks to an interference phenomenon between the light reflecting off the surface of the clear oxide layer and the light reflecting off the metal surface that has passed through the oxide layer and been refracted back. Through careful manipulation of this interference phenomenon, by controlling the depth of the oxide layer within a range of 100-300nm, various colours can be achieved: black, gold, bronze, and more. Since the oxide layer is clear, it can enhance the qualities of finishes such as HL, PHL (vibration), and mirror polishes.

★Unlike paint, this colour will not fade even in sunlight, thanks to the interference colour of the amorphous passivation film.

★Being coated in a passivation film that is many dozens of times thicker than the chrome oxide layer of untreated stainless steel means enhanced weatherability and corrosion resistance

★Antique looks can be achieved by deliberately incorporating colour inconsistencies for a natural finish

✓The finish is highly robust, but does have some drawbacks in wear resistance

✓There are limitations to the fabrication methods with which coated materials can be used

✓Difficult to repair

✓There may be a slight difference between the colour sample provided by the manufacturer and the finished colour

Click here for more about our KC-Colour + Silica Coating (SAN) finish

●Physical vapour deposition (PVD, Sputtering): KS-Coating

In this method, a small amount of argon gas is added to a high vacuum chamber which is then subjected to a high voltage. Ions from the argon plasma then collide with the coating material, causing it to eject molecules which are the deposited on, and adhere firmly to, the stainless steel substrate. Known as “sputtering”, this colouring method causes the surface of the stainless steel to be coated with the target material (ceramics such as titanium nitride or carbide) at a depth of 300nm.

★This colour product boasts tones unique to ceramics, and makes the best possible use of the stainless steel base.

★Brighter and more consistent colour can be achieved in comparison to chemical colouring

★Results in beautiful, crystalline colours, with the gold finish being particularly close to real gold

★The hard layer of beautiful ceramic means outstanding resistance to wear, while scratch hardness is three times that of chemically coloured stainless steel.

✓There are limitations to the fabrication methods with which coated materials can be used

✓Difficult to repair

✓There may be a slight difference between the colour sample provided by the manufacturer and the finished colour

Click here for more about our KS-Coating + Silica Coating (SPT) finish

The Reiyukai Headquarters, completed in 1975: the main hall features ceiling panels in Chemical Colouring (Gold), fabricated using molding press technology

Stainless steel panels coloured using physical vapour deposition (PVD, sputtering)

(Left) Ceiling and wall panels in HL + Black (Right) Wall panels in PHL (Vibration) + Bronze

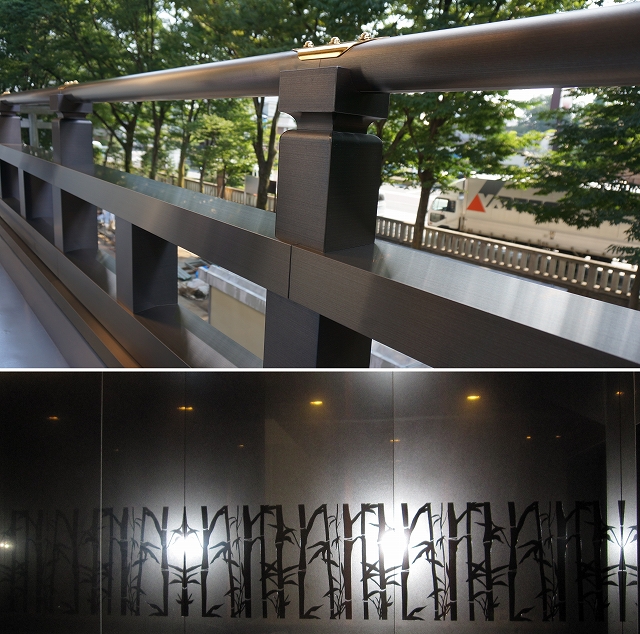

(Top) Stainless steel handrail in HL + Chemical Colouring (Amber): the colour was achieved after post-processing trial-and-error

(Bottom) Stainless steel panels in PHL (Vibration) + Chemical Colouring (Black): the bamboo pattern was etched then painted in black

Coloured Stainless Steel through other methods

(Left) Bronze-effect Colour Clear Coated partitions (Right) HL+Black Nickel Plating on external panels