April 11, 2023

Updated Aluminium Sample Book Now Available

Updated Aluminium Sample Book Now Available

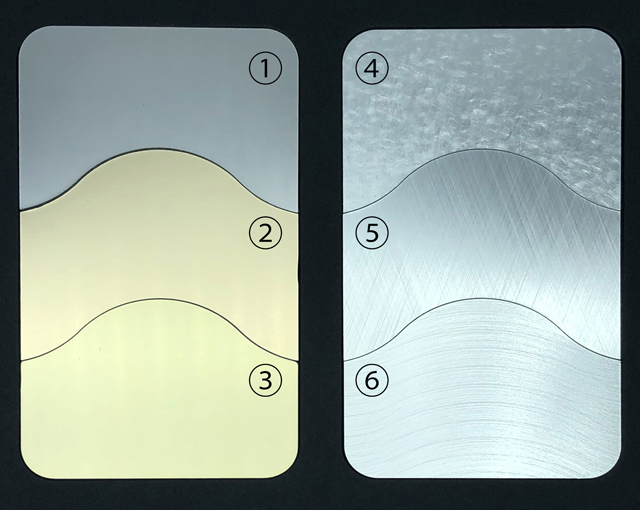

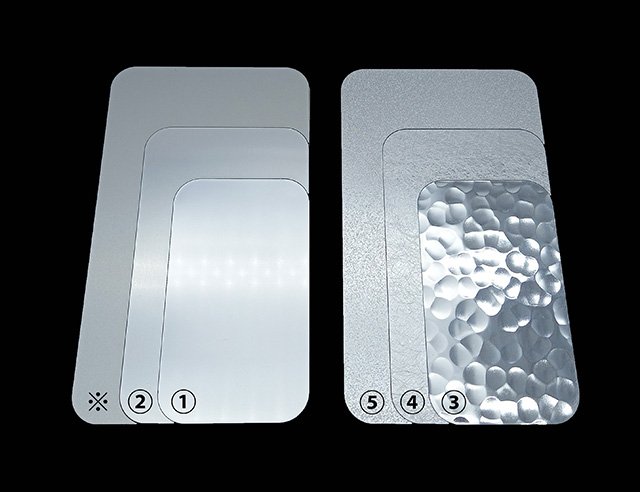

Featuring an extensive range of gloss, polished, and processed finishes

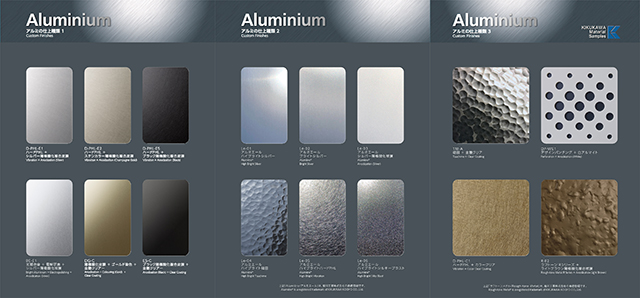

KIKUKAWA, a bespoke metal architect for interiors and exteriors, released an updated version of our Aluminium Sample Book on March 1, 2023. The updated version features 16 of our aluminium finishes and includes some of our new finish options.

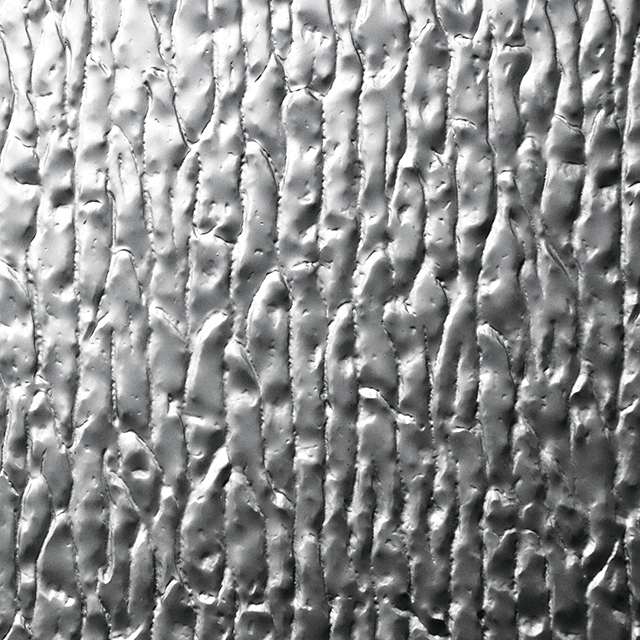

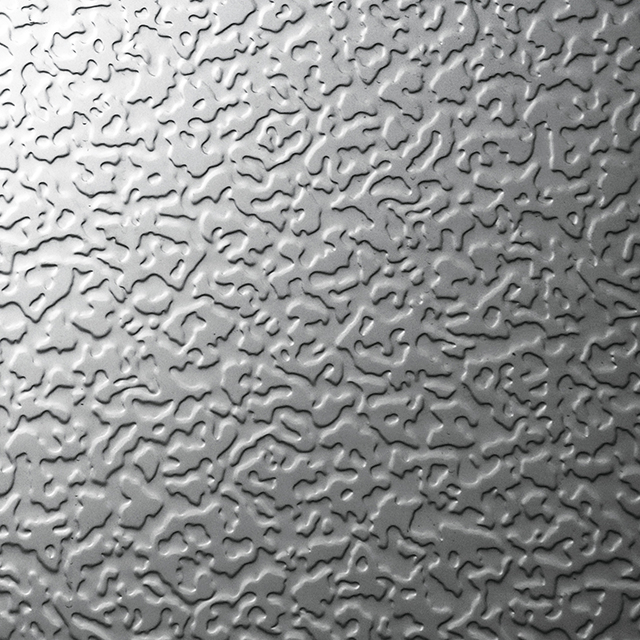

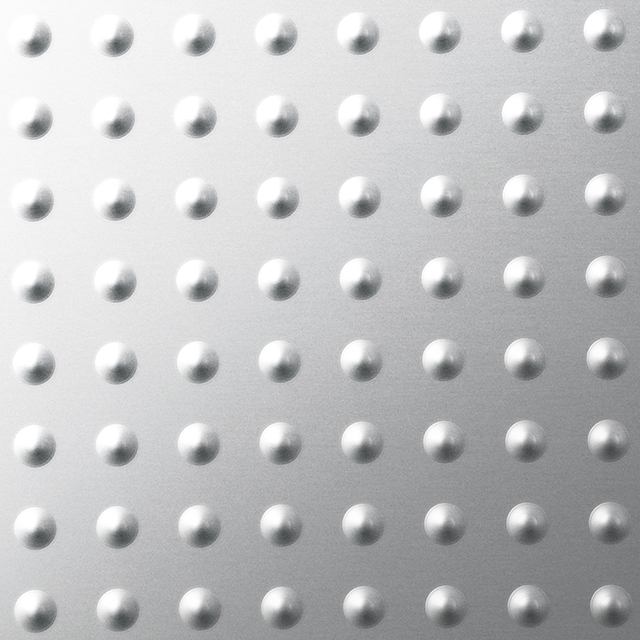

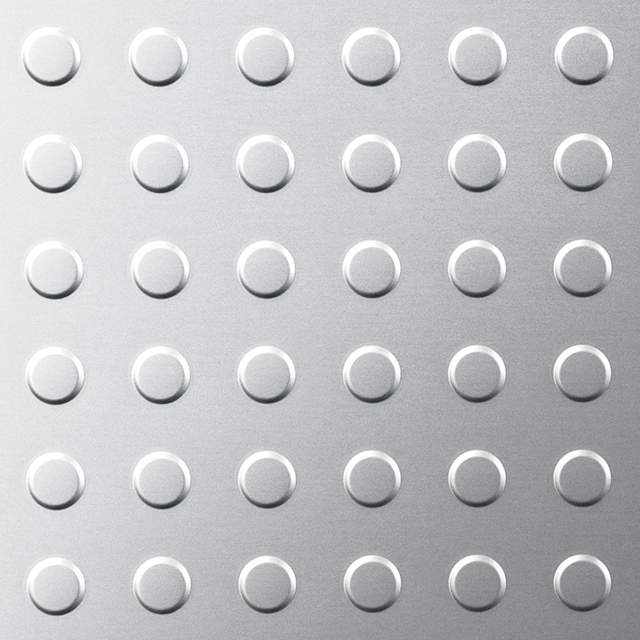

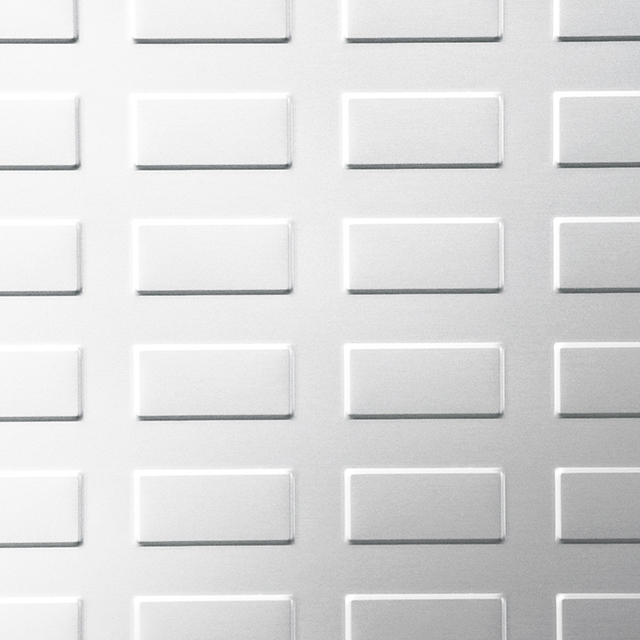

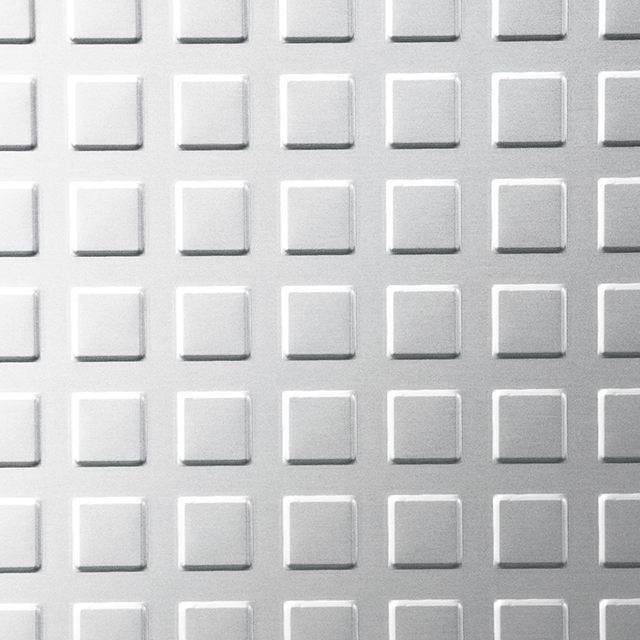

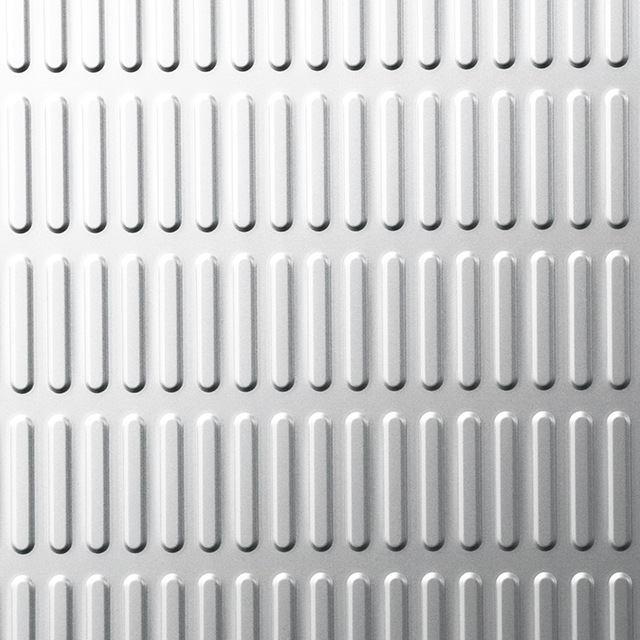

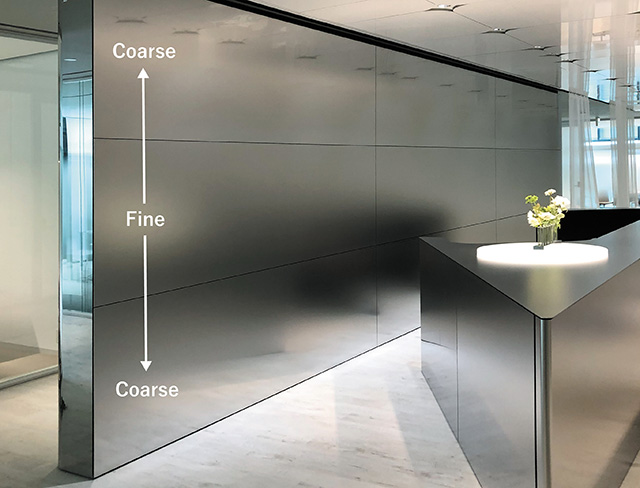

The featured samples have been selected as a visual showcase of the diversity of our aluminium finishes and represent some of the most decorative finish options we offer. Ten of the samples are new additions to the Aluminium Sample Book, including: finishes from our Alumiére®* range, which are designed to add shine and texture to luminous aluminium alloys; a perforated finish, which makes maximum use of the high processability of aluminium; and an embossed finish that evokes cast metal.

Popular finishes from the previous version of the Aluminium Sample Book, including those used in projects such as the Sumida Hokusai Museum and the Tokyo Metropolitan Teien Art Museum, are also listed in this new edition.

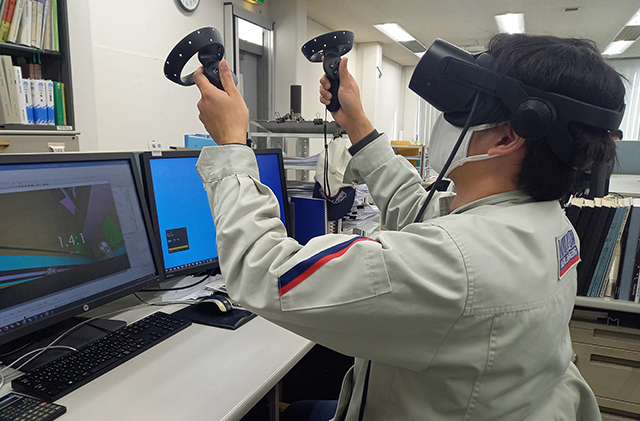

Through our extensive experience to date of projects tailored to client specifications, KIKUKAWA is able to propose various combinations from our wide range of finishes and processing options to best meet client needs. We are also highly adaptable, which enables us to make tailored adjustments to colour tone and shine. Aluminium finishes are a great choice for both interior and exterior applications.

Through this new edition of the Aluminium Sample Book, we intend to widen the selection of aluminium as a building material with various potential looks and in doing so increase the breadth of design options available to clients such as project owners, developers, architects and designers.

*Alumiére®: a Kikukawa original range of finishes designed to add gentle shine and polished textures to aluminium.

■Aluminium Sample Book: The new line-up of finishes

・Defined PHL (vibration) + Anodization (silver / silver tone / black)

・Bright Aluminium alloy + Electrolytic polishing + Anodization

・Anodization + Dyeing (gold) + Clear Coating

・Anodization (black) + Clear Coating

● Alumiére® (6 finishes)

● Tsuchime (Hammertone) + Clear Coating

● Bespoke perforation + Anodization (white)

● Defined PHL + Colour Clear Coating

● ‘Rough Tone Metal’ R Series + Anodization (light brown)

● denotes new additions to the listed finishes.

*Please note that workable panel thickness and size differs for each finish.

Click here to learn more about Kikukawa’s Finish Samples -Aluminium